Process of removing sulfur and ammonia from coke gas to prepare ammonia water

A coke oven gas and ammonia water technology, applied in the chemical industry, can solve problems such as high production management requirements, low sulfur purity, and poor ammonia purification effect, and achieve the effects of reducing waste water discharge, saving steam consumption, and reducing environmental protection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

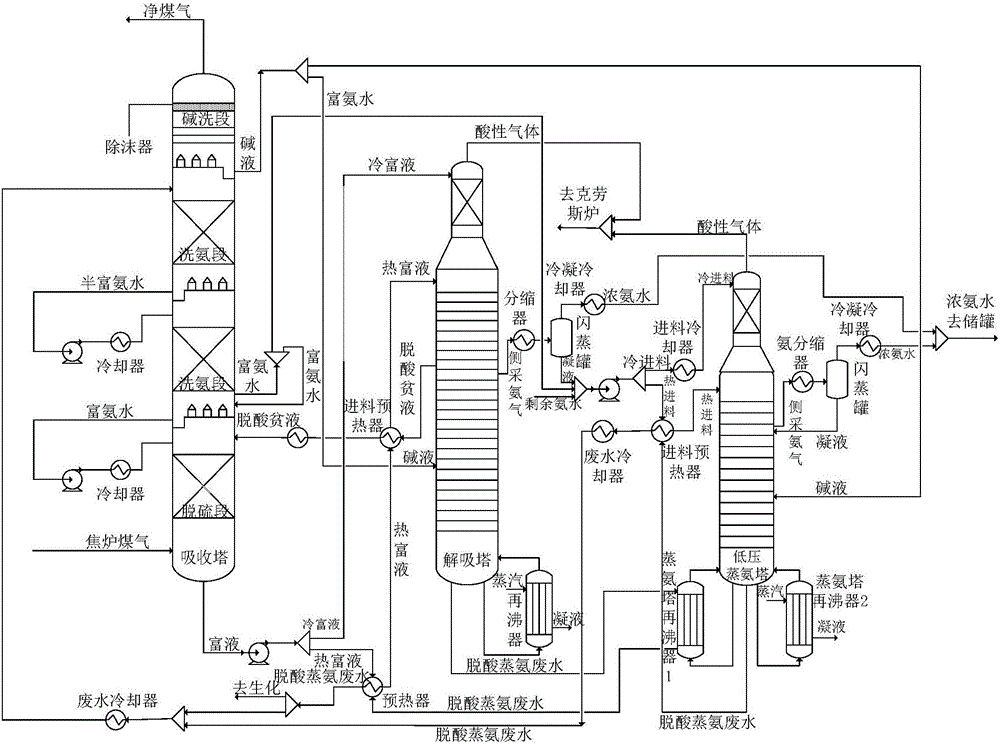

[0018] The invention provides a process for preparing ammonia water by desulfurization and deammonification of coke oven gas (see figure 1 ), characterized in that the process comprises the following steps:

[0019] (1) Absorption part of ammonia and hydrogen sulfide: the main equipment of the absorption part includes absorption tower, supporting heat exchanger, storage tank, etc. The absorption tower is composed of desulfurization section, ammonia washing section and alkali washing section from bottom to top. The temperature is 22~25℃, the ammonia content is 6~8g / Nm 3 , hydrogen sulfide content is 6 ~ 8g / Nm 3 The coke oven gas first enters the desulfurization section in the lower part of the absorption tower, and all or part of the amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com