Microbial carrier for wrapping biological coating on ceramic hollow rod and preparation method

A microbial carrier and bio-coating technology, applied in the field of environmental protection, can solve the problems of fiber filaments not having physical and mechanical properties, microorganisms are not easy to attach, secondary pollution, etc., to shorten the time of stable maturation, excellent physical and mechanical properties, The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

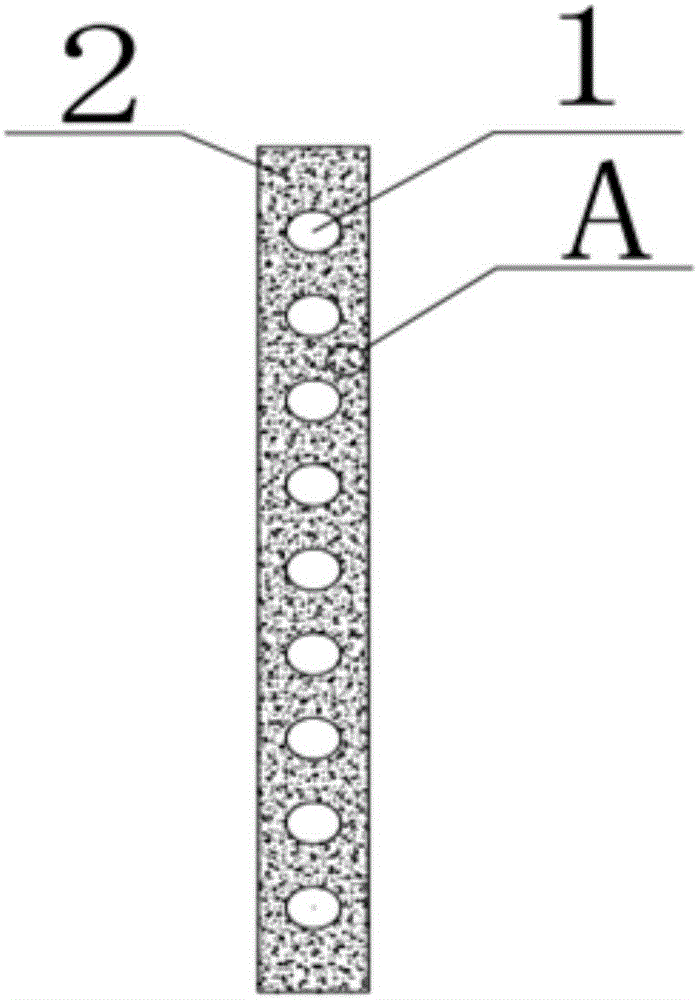

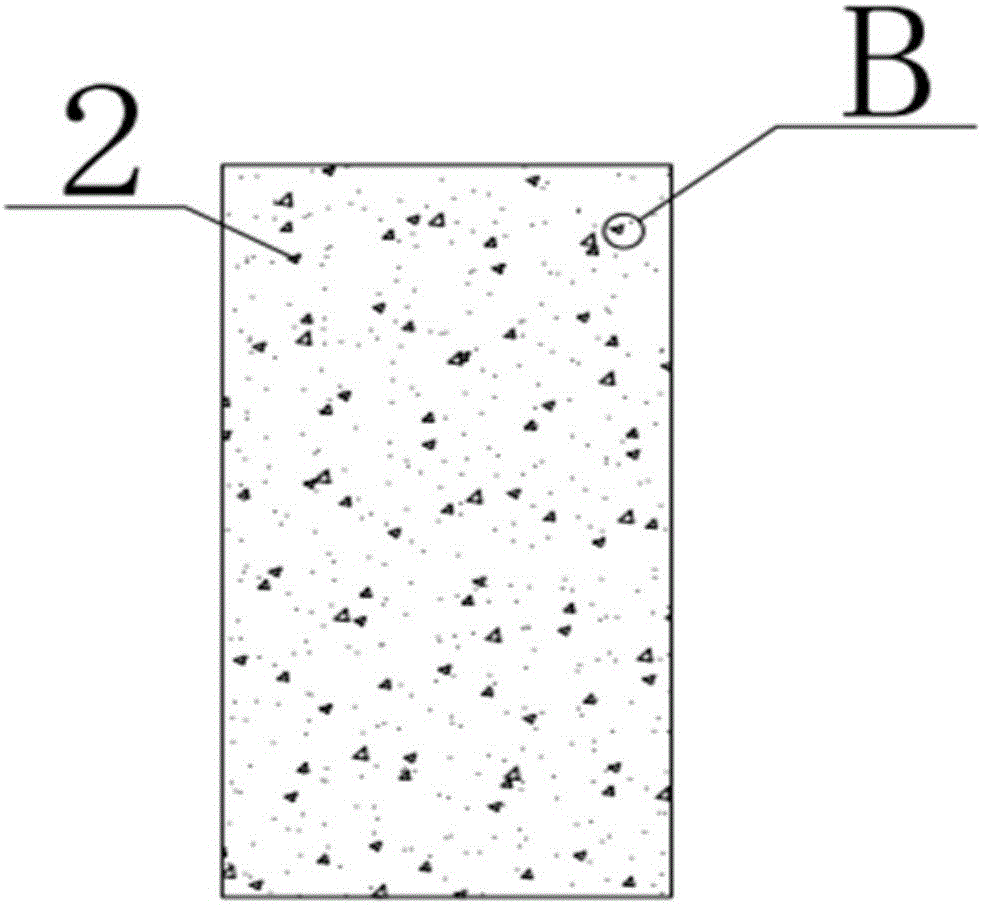

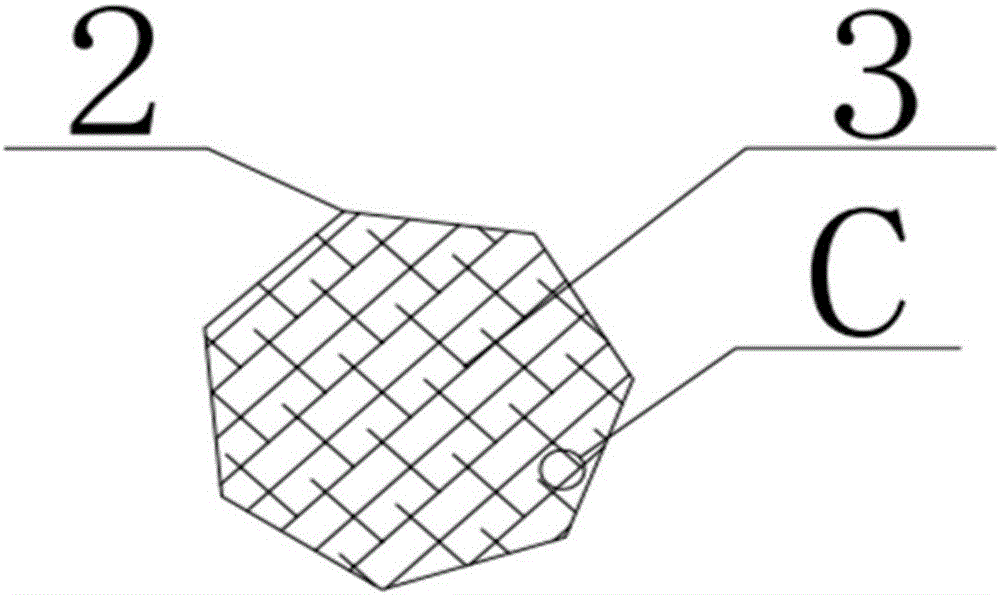

[0027] please see Figure 1-Figure 4 The present invention provides a microbial carrier wrapped with a biological coating on a ceramic hollow rod. The ceramic hollow rod is fired from modified iron tailings, regenerated activated carbon, expanded perlite, and gypsum mixed materials to form several hollows 1 and multiple Pore 2 structure; the pores 2 of the ceramic hollow rod are filled with bio-coating, and the surface of the ceramic hollow rod is covered with a biological coating 3; both the pores 2 and the bio-coating 3 of the ceramic hollow rod are attac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com