A kind of polyimide self-porous polymer membrane containing crown ether micropores and preparation method thereof

A microporous polymer and polyimide technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of wide pore size distribution, difficult control of micropore size, unfavorable gas selectivity, etc. Achieve the effect of increasing free volume, easy synthesis, and improving sieving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

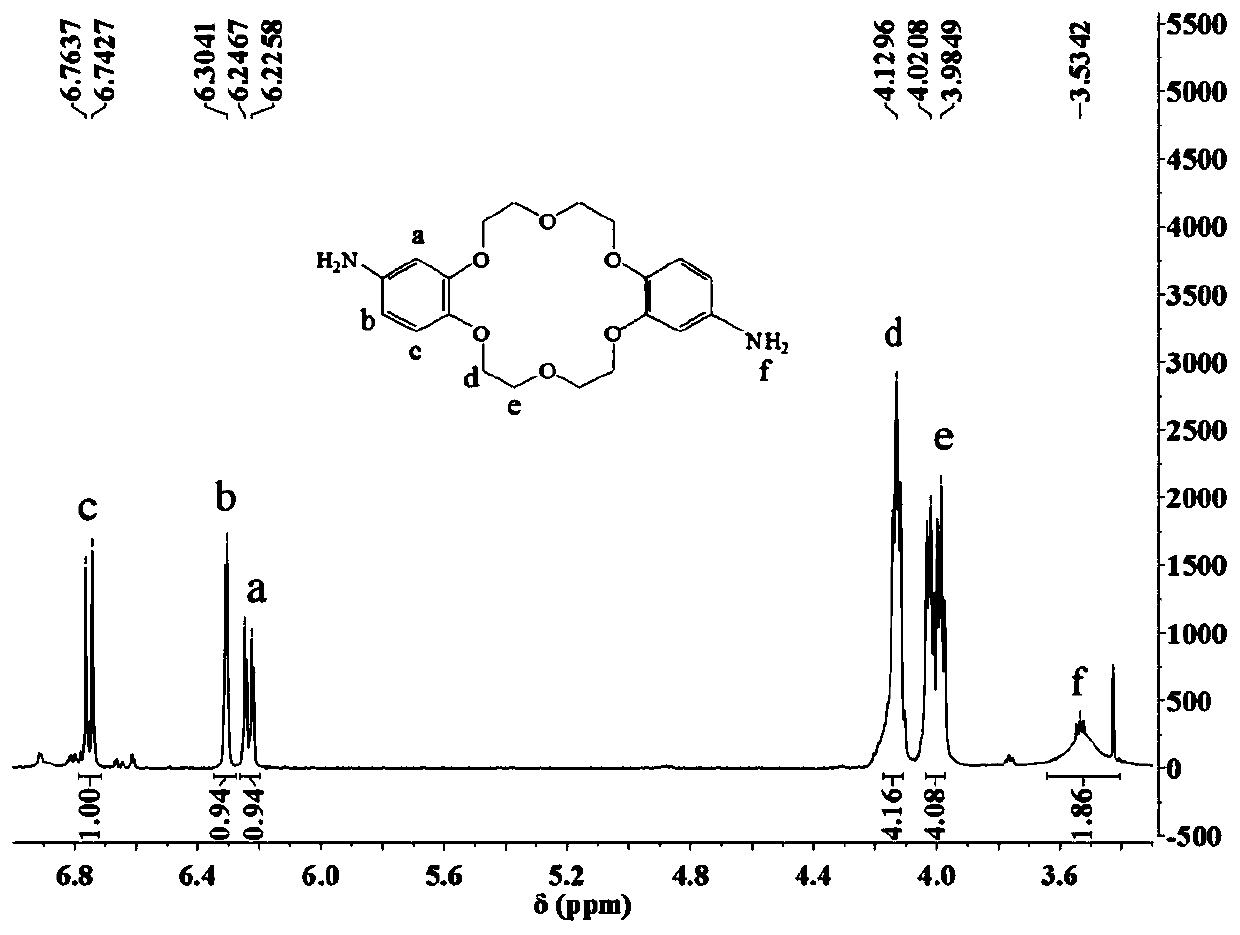

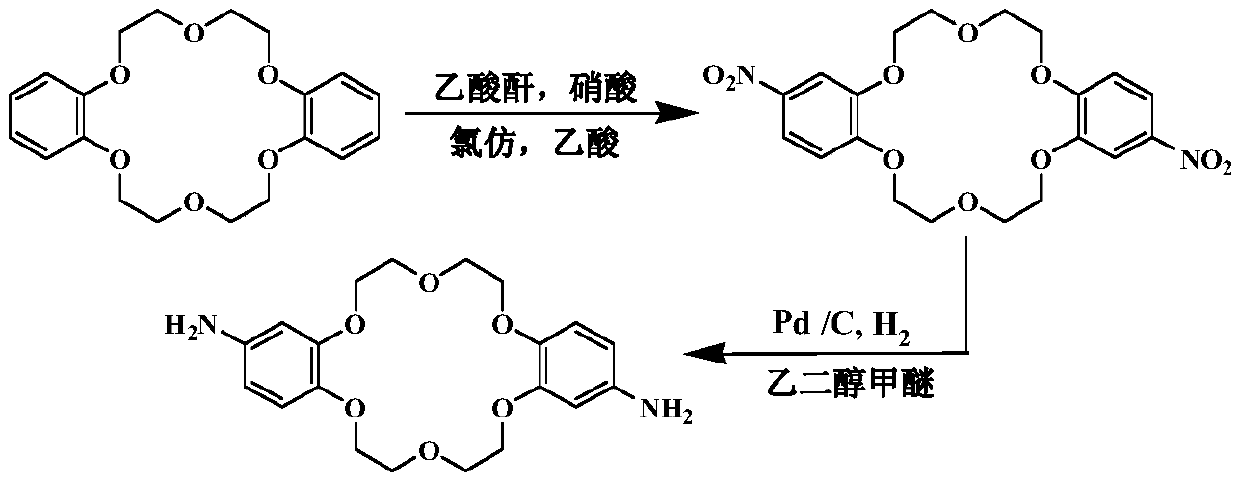

[0030] (1) Preparation of crown ether compounds; Crown ether compounds include diaminodibenzo-15-crown-5, diaminodibenzo-18-crown-6 or diaminodibenzo-21-crown-7, the following Taking the preparation of diaminodibenzo-18-crown-6 as an example to illustrate, when preparing other crown ether compounds, replace the dibenzo-18-crown-6 in the raw material with dibenzo-15-crown-5 or Dibenzo-21-crown-7 is sufficient.

[0031] Dissolve dibenzo-18-crown-6 in a mixed solvent composed of chloroform and glacial acetic acid to obtain dibenzo-18-crown-6 solution; add nitric acid and acetic anhydride mixture to dibenzo-18 -Crown-6 solution, wherein the ratio of dibenzo-18-crown-6, chloroform, glacial acetic acid, nitric acid and acetic anhydride is (0.0125~0.0153)mol:(95~115)mL:(70~80) mL: (3~4.5)mL: (13.5~15.5)mL; react at 10~25°C for 1~1.5h, raise the temperature to 40~80°C and continue to react for 5~6h, filter the yellow precipitate, recrystallize, and vacuum dry, namely Trans-dinitrodi...

Embodiment 1

[0042] (1) Preparation of diaminodibenzo-18-crown-6

[0043] Dissolve 0.0142mol of dibenzo-18-crown-6 in a mixed solvent consisting of 105mL of chloroform and 75mL of glacial acetic acid, and add 3.6mL of nitric acid and 14.25mL of acetic anhydride to dibenzo-18-crown-6 dropwise. In the solution, react at -17°C for 1.2h, raise the temperature to 50°C and continue to react for 5.5h, filter the yellow precipitate, recrystallize at 150°C, and dry in vacuum to obtain trans-dinitrodibenzo- 18-Crown-6, its yield can reach 62.9mol%; the filtrate stands still, and almost no cis product is precipitated.

[0044] Dissolve the prepared 0.0037mol of dinitrodibenzo-18-crown-6 in 100mL of ethylene glycol methyl ether to prepare a reaction solution with a concentration of 0.037mmol / mL, and add the reaction solution to the reaction kettle; Base dibenzo-18-crown-6 mass 4% Pd / C catalyst, then filled with H 2 to 0.35MPa, stir and heat up, and react at 75°C for 2.5h; filter the solution in the ...

Embodiment 2

[0055] (1) The preparation method of diaminodibenzo-18-crown-6 is the same as step (1) in Example 1.

[0056] (2) Preparation of crown ether microporous polyimide self-porous polymers

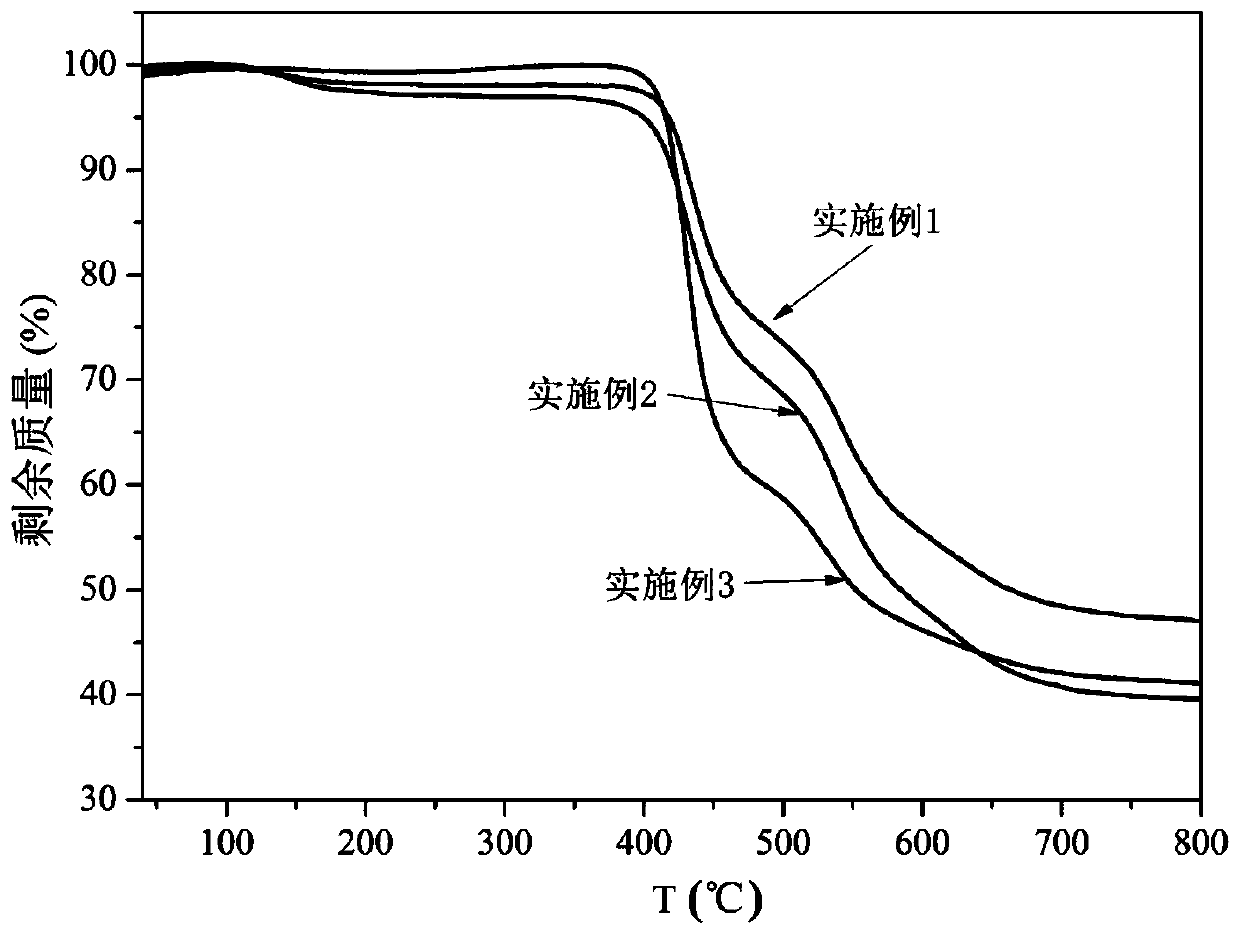

[0057] Under nitrogen protection, mix diaminodibenzo-18-crown-6 with commercial 4,4'-diaminodiphenylmethane at a molar ratio of 0.33, add N,N-dimethylacetamide, and magnetically stir Dissolved to obtain a diamine solution; according to the molar ratio of aromatic diamine to aromatic dianhydride as 1:1, add 4,4'-hexafluoroisopropylphthalic anhydride solid directly into the diamine solution to prepare Prepare a solution with a total mass fraction of aromatic diamine and aromatic dianhydride of 18wt%, and stir at room temperature for 9 hours; The ratio is 2:1, add a mixture of acetic anhydride and triethylamine, stir at 50°C for 3h; cool to room temperature, desolventize the final reaction solution, remove impurities, and vacuum dry at 90°C for 24h to obtain the Porous polyimides are microporous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com