Method for separating and recovering waste cotton-polyester blended fabric under subcritical water condition

A polyester-cotton blended, subcritical water technology is applied in the field of separation and recycling of waste polyester-cotton fabrics, which can solve the problems of inability to separate cotton fibers and polyester fibers, unsatisfactory separation effect, and high recycling cost, and achieves less environmental pollution and less corrosiveness. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

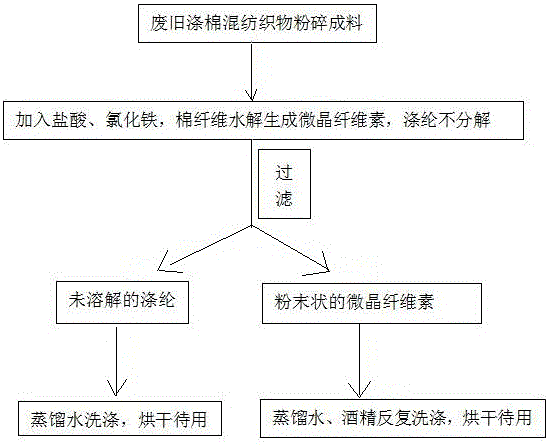

Image

Examples

Embodiment 1

[0029] Embodiment 1: the dilute hydrochloric acid of different mass fraction concentration is used for the recycling of waste polyester-cotton blended fabric

[0030] (1) Raw materials

[0031] 1. Waste polyester-cotton blended fabric, the blending ratio is 65:35;

[0032] 2. Hydrochloric acid and ferric chloride;

[0033] (2) Method

[0034] 1. Crush waste polyester-cotton blended fabrics into materials, add hydrochloric acid solutions with mass fractions of 0.5%, 1%, 1.5%, 2%, and 2.5% respectively, and keep the solid-liquid ratio at 1:25, and keep the temperature constant at 150 ℃ to start the reaction, the reaction time is 5h.

[0035] 2. Stir the reacted solution, and filter it with a medium-speed filter paper, wash the solid product on the sieve with water and alcohol for several times, rinse it and dry it for use.

[0036] The principle in the reaction process is that cotton fiber is a cellulose fiber formed by cellulose macromolecules, and the 1-4β glycoside bonds ...

Embodiment 2

[0039] Embodiment 2: Different reaction times are used for the recycling of waste polyester-cotton blended fabrics

[0040] (1) Raw materials

[0041] 1. Waste polyester-cotton blended fabric, the blending ratio is 75:25;

[0042] 2. Hydrochloric acid and ferric chloride.

[0043] (2) Method

[0044] 1. Crush the waste polyester-cotton blended fabric into materials, add hydrochloric acid solution with a mass fraction of 0.5% and 0.3g ferric chloride respectively, and keep the solid-liquid ratio at 1:25, keep the temperature constant at 150°C to start the reaction, and the reaction time It is 2h, 3h, 4h, 5h, 6h.

[0045] 2. Stir the reacted solution, and filter it with a medium-speed filter paper, wash the solid product on the sieve with water and alcohol for several times, rinse it and dry it for use.

[0046] (3) Experimental results

[0047] It was determined that after the reaction time was 2h, 3h, 4h, 5h, and 6h, the recovery rate of polyester reached 100%, and the yi...

Embodiment 3

[0048] Embodiment 3: Different reaction temperatures are used for the recycling of waste polyester-cotton blended fabrics

[0049] (1) Raw materials

[0050] 1. Waste polyester-cotton blended fabric, the blending ratio is 75:25.

[0051] 2. Hydrochloric acid and ferric chloride

[0052] (2) Method

[0053] 1. Crush the waste polyester-cotton blended fabric into materials, add hydrochloric acid solution with a mass fraction of 1% and 0.2g ferric chloride respectively, and keep the solid-liquid ratio at 1:25, and keep the temperature constant at 130°C, 140°C, 150°C ℃, 160℃, 170℃, and the reaction time is 5h.

[0054] 2. Stir the reacted solution, and filter it with a medium-speed filter paper, wash the solid product on the sieve with water and alcohol for several times, rinse it and dry it for use.

[0055] (3) Experimental results

[0056] It was determined that after the reaction temperatures were 130°C, 140°C, 150°C, 160°C, and 170°C, the recovery rates of polyester reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com