Polyester self-nucleating agent as well as preparation method and application thereof

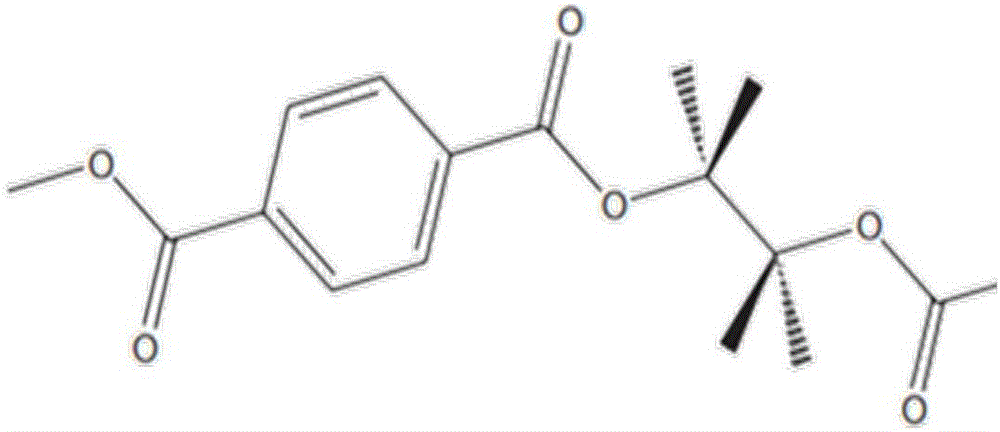

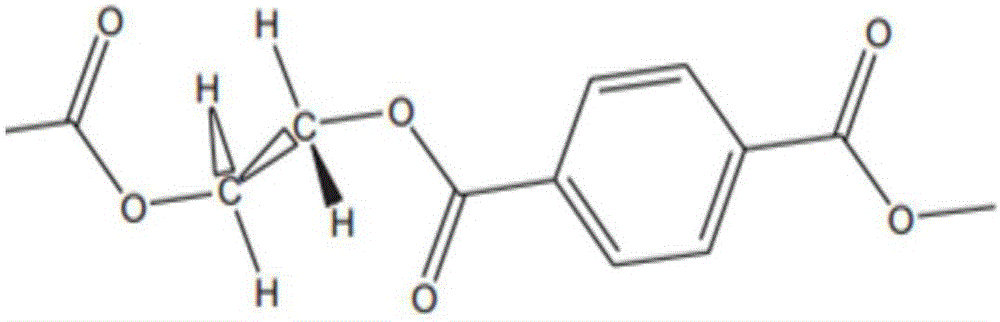

A self-nucleating, polyester technology, applied in the field of resin materials, can solve the problems of PET molecular weight reduction, high price of trifluoroacetic acid, strong volatility and corrosion, etc., achieve rapid crystallization ability, do not cause molecular weight drop, and promote crystallization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

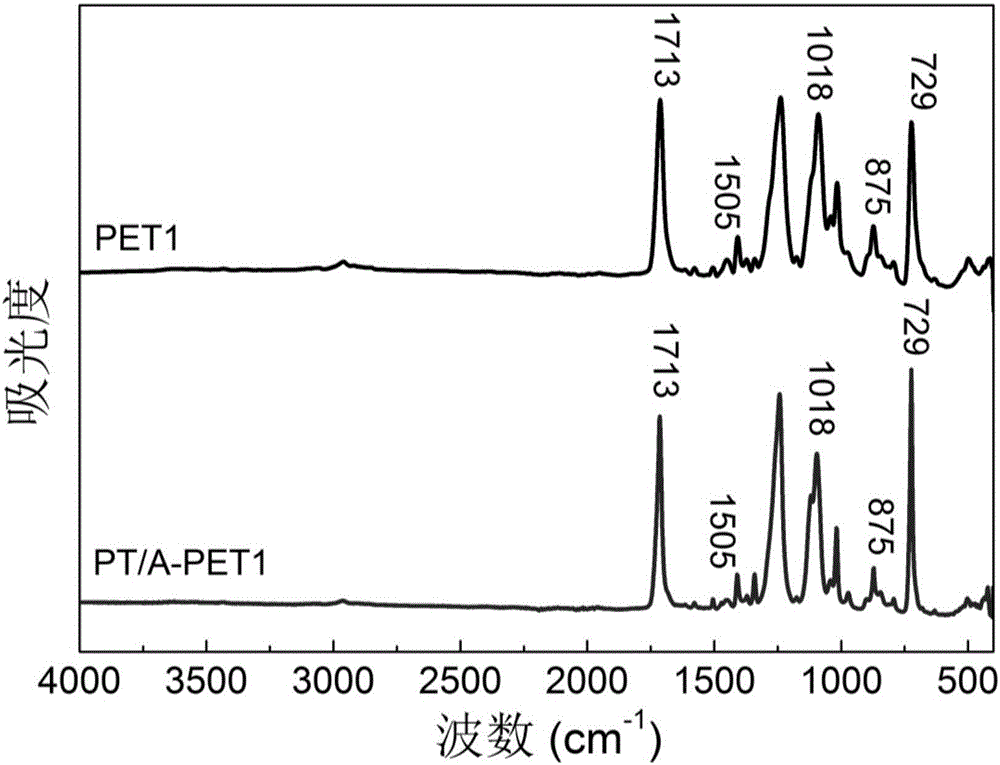

[0058] A kind of PET self-nucleating agent that can crystallize rapidly, its preparation process is as follows:

[0059] (1) Set the intrinsic viscosity to 0.82dL·g -1 The PET1 resin was dissolved in phenol / tetrachloroethane mixed solvent to obtain a PET solution with a concentration of 0.06g / mL. In the phenol / tetrachloroethane mixed solvent, the mass ratio of phenol to tetrachloroethane was 3:2 ;

[0060] (2) at a stirring speed of 600rpm, the PET solution obtained in step (1) is added in acetone to obtain a mixture containing a white precipitate, and the volume ratio of the acetone precipitating agent to the PET solution is 3:1;

[0061] (3) The mixture containing the white precipitate obtained in step (2) is subjected to vacuum suction filtration to obtain a white precipitate; the white precipitate is washed with acetone and distilled water in turn, and then vacuum-dried at 60°C to constant weight to obtain a molecular chain in the form of Kink The conformation-based PET ...

Embodiment 2

[0063] A kind of PET self-nucleating agent masterbatch that can crystallize rapidly, its preparation process is as follows:

[0064] (1) The PET self-nucleating agent (PT / A-PET1) obtained in Example 1 and the intrinsic viscosity are 0.69dL·g -1 The PET2 resin was blended in a Brabender torque rheometer, the temperature of the rheometer was 275°C, the rotation speed was 80r / min, the blending time was 5min, and the dosage of the PET self-nucleating agent was 5wt% of the PET2 resin mass ;

[0065] (2) Dry the blend obtained in step (1) to a constant weight in a vacuum oven at 60°C to obtain a PET self-nucleating agent masterbatch containing 5wt% PT / A-PET1, denoted as PT / A-PET1 The properties of PET masterbatch are shown in Table 1.

Embodiment 3

[0067] A kind of application of the PET self-nucleating agent prepared by embodiment 1:

[0068] (1) The PET self-nucleating agent (PT / A-PET1) obtained in Example 1 and the intrinsic viscosity are 0.69dL·g -1 The PET2 resin was blended in a Brabender torque rheometer, the temperature of the rheometer was 275°C, the rotation speed was 80r / min, the blending time was 5min, and the dosage of the PET self-nucleating agent was 1wt% of the PET2 resin mass ;

[0069] (2) Dry the blend obtained in step (1) to a constant weight in a vacuum oven at 60° C. to obtain a modified PET polyester containing 1 wt % PET self-nucleating agent (PT / A-PET1). It is 1% PT / A-PET1+PET2, and its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com