A kind of temperature-resistant and salt-resistant anti-swelling clay stabilizer and its synthesis method

A technology of clay stabilizer and synthesis method, which is applied in the direction of chemical instruments and methods, drilling compositions, preparation of organic compounds, etc., which can solve the problem of limiting application range, reducing formation permeability, and clay stabilizer's heat and salt resistance To achieve the effect of wide range of raw material sources, good compatibility and strong reservoir adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Clay Stabilizer A 1 and its preparation method

[0027] (1) Clay Stabilizer A 1 The composition, components and molecular formula are as follows:

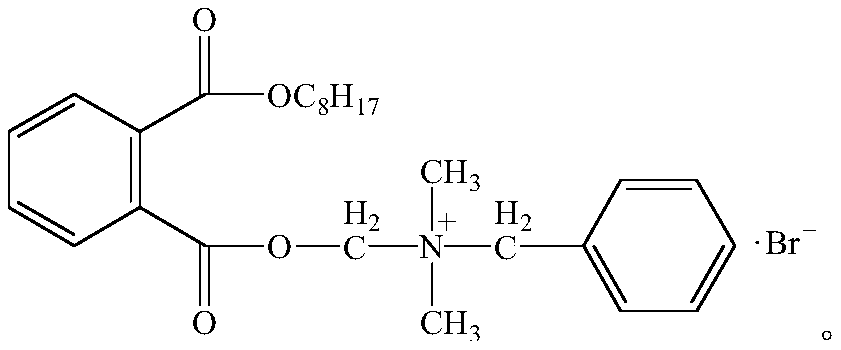

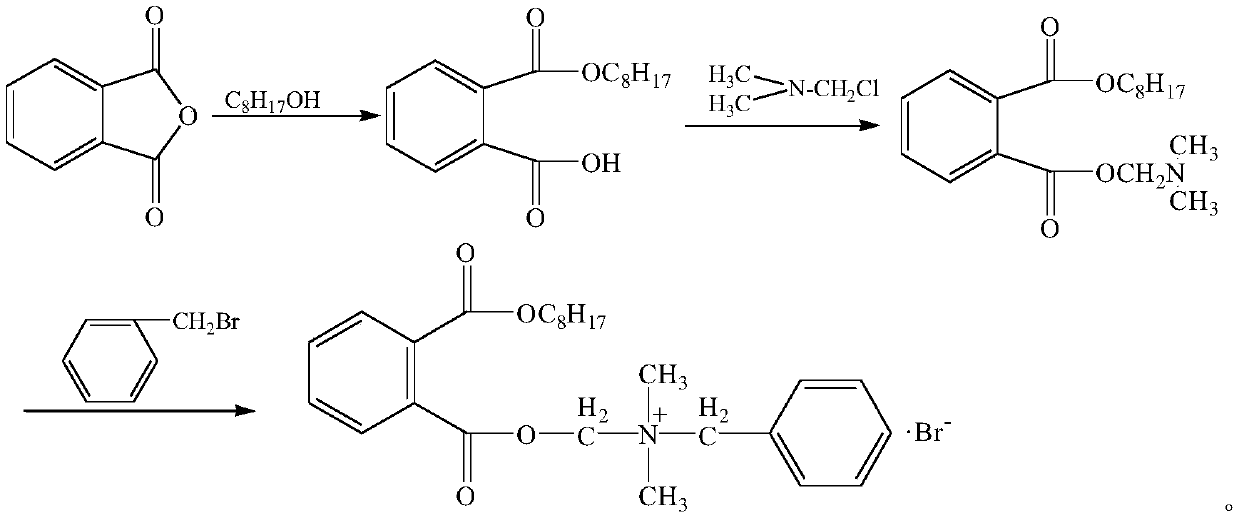

[0028] Clay Stabilizer A 1 It is obtained by reacting phthalic anhydride, n-octanol, dimethylaminomethane chloride and benzyl bromide in a molar ratio of 1:0.9:1.1:1.3. Its molecular formula is as follows:

[0029]

[0030] (2) Clay Stabilizer A 1 The synthesis method is as follows:

[0031] ① Add 1mol of phthalic anhydride and 0.9mol of n-octanol into a four-neck flask, heat to 60°C, stir at 200rpm, and react for 1h, then add 1481.1g of n-heptane, react for 2h, then Cool down to room temperature and stir for 15 minutes to obtain n-octyl phthalic anhydride half ester solution;

[0032] ②Add 1.1 mol of dimethylaminomethane chloride to the above half-octyl phthalic anhydride solution, and react while stirring. The stirring rate is 330rpm, and the reaction time is 5h. Reaction, the stirring rate is 400rp...

Embodiment 2

[0037] Example 2: Clay Stabilizer A 2 and its preparation method

[0038] (1) Clay Stabilizer A 2 The composition, components and molecular formula are as follows:

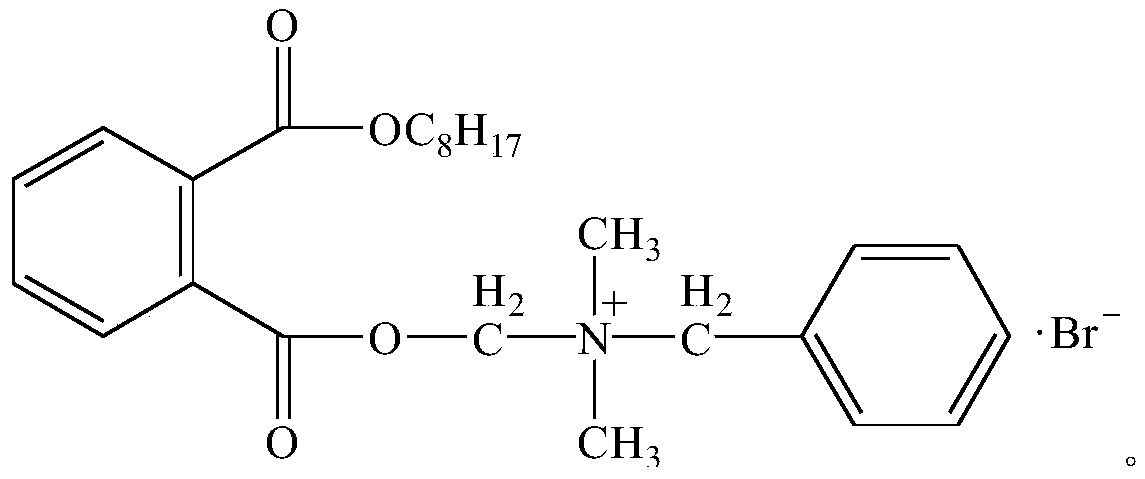

[0039] Clay Stabilizer A 2It is obtained by reacting phthalic anhydride, n-octanol, dimethylaminomethane chloride and benzyl bromide in a molar ratio of 1:1.1:1.3:1.6. Its molecular formula is as follows:

[0040]

[0041] (2) Clay Stabilizer A 2 The synthesis method is as follows:

[0042] ① Add 1mol of phthalic anhydride and 1.1mol of n-octanol into a four-neck flask, heat to 70°C, stir at 220rpm, and react for 1.5h, then add 1856.3g of n-heptane, and react for 4h. Cool to room temperature subsequently, stir 20min, obtain n-octyl phthalic anhydride half ester solution;

[0043] ②Add 1.3 mol of dimethylaminomethane chloride to the n-octyl phthalic anhydride half-ester solution, and react while stirring. The stirring rate is 300rpm, and the reaction time is 10h. Reaction, the stirring rate is 500rpm, the...

Embodiment 3

[0048] Example 3: Clay Stabilizer A 3 and its preparation method

[0049] (1) Clay Stabilizer A 3 The composition, components and molecular formula are as follows:

[0050] Clay Stabilizer A 3 It is obtained by reacting phthalic anhydride, n-octanol, dimethylaminomethane chloride and benzyl bromide in a molar ratio of 1:1.2:1.5:1.8. Its molecular formula is as follows:

[0051]

[0052] (2) Clay Stabilizer A 3 The synthesis method is as follows:

[0053] ①Add 1mol of phthalic anhydride and 1.2mol of n-octanol into a four-neck flask, heat to 80°C, stir at 250rpm, and react for 2h, then add 2221.6g of n-heptane, react for 6h, then Cool down to room temperature and stir for 30 minutes to obtain n-octyl phthalic anhydride half ester solution;

[0054] ② Add 1.5 mol of dimethylaminomethane chloride to the n-octyl phthalic anhydride half-ester solution, and react while stirring. The stirring rate is 350rpm, and the reaction time is 8h. Reaction, the stirring rate is 450rpm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com