Environment-friendly filling oil preparation method

A filling oil, environmental protection technology, applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc., can solve the problems of no environmental protection treatment of polycyclic aromatic hydrocarbon oil, TDAE is not green and environmental protection, can not further enhance the value, etc. Superior processing performance, improved resource utilization, good wet skid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

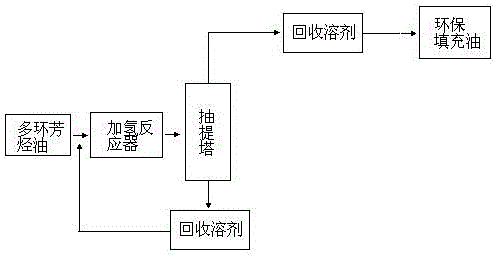

[0023] Use the extracted oil of high aromatic oil used for tire rubber filling as raw material, put it in a hydrogenation reactor for hydrogenation treatment, obtain hydrogenation treatment oil, and remove a small amount of hydrogen sulfide, ammonia, etc. dissolved in the hydrogenation treatment oil by air stripping Light component, hydrotreated oil is extracted with solvent to obtain raffinate and extract, the raffinate is desolventized to be environmentally friendly filler oil, the extract is desolventized to obtain extracted oil, and the extracted oil is sent to hydrogenation reaction Hydrotreating in the device, and then placed in the extraction tower for solvent extraction, and so on.

[0024] The reaction conditions in the hydrogenation reactor are: temperature 350°C, pressure 10MPa, volume fraction ratio of hydrogen to the polycyclic aromatic hydrocarbon oil 1000:1, space velocity 1h -1 .

[0025] The solvent used for solvent extraction is dimethyl sulfoxide, the numbe...

Embodiment 2

[0028] Use the extracted oil of high aromatic oil used for tire rubber filling as raw material, put it in a hydrogenation reactor for hydrogenation treatment, obtain hydrogenation treatment oil, and remove a small amount of hydrogen sulfide, ammonia, etc. dissolved in the hydrogenation treatment oil by air stripping Light component, hydrotreated oil is extracted with solvent to obtain raffinate and extract, the raffinate is desolventized to be environmentally friendly filler oil, the extract is desolventized to obtain extracted oil, and the extracted oil is sent to hydrogenation reaction Hydrotreating in the device, and then placed in the extraction tower for solvent extraction, and so on.

[0029] The reaction conditions in the hydrogenation reactor are: temperature 300°C, pressure 12MPa, volume fraction ratio of hydrogen to the polycyclic aromatic hydrocarbon oil 1500:1, space velocity 1.5h -1 .

[0030] The solvent for solvent extraction is N-methylpyrrolidone, the number ...

Embodiment 3

[0033] Use the extracted oil of high aromatic oil used for tire rubber filling as raw material, put it in a hydrogenation reactor for hydrogenation treatment, obtain hydrogenation treatment oil, and remove a small amount of hydrogen sulfide, ammonia, etc. dissolved in the hydrogenation treatment oil by air stripping Light component, hydrotreated oil is extracted with solvent to obtain raffinate and extract, the raffinate is desolventized to be environmentally friendly filler oil, the extract is desolventized to obtain extracted oil, and the extracted oil is sent to hydrogenation reaction Hydrotreating in the device, and then placed in the extraction tower for solvent extraction, and so on.

[0034] The reaction conditions in the hydrogenation reactor are: temperature 370°C, pressure 8MPa, volume fraction ratio of hydrogen to the polycyclic aromatic hydrocarbon oil 600:1, space velocity 0.7h -1 .

[0035] The solvent for solvent extraction is phenol, the extraction stage is 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com