Compound glass cutting fluid

A composite glass and cutting fluid technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of easily corroded printed circuits, etc., and achieve the effects of ensuring safety, reducing corrosion rate, and improving lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

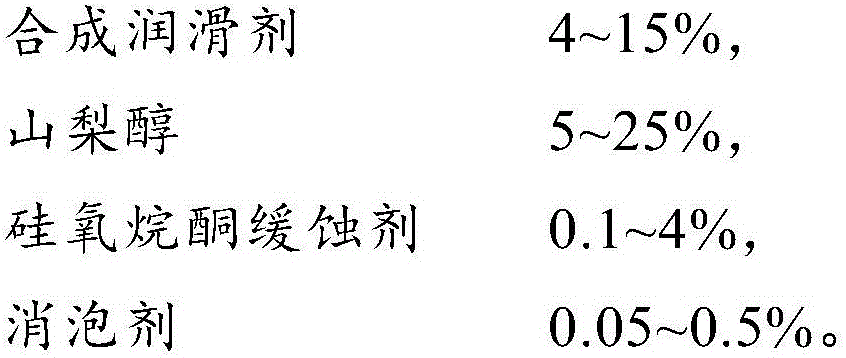

[0023] A kind of composite glass cutting fluid, the raw material composition by mass percentage is as follows:

[0024]

[0025]

[0026] Heat the 5% dilution of the composite glass cutting fluid of this embodiment and keep the temperature constant at 50±2°C, soak the OGS glass workpiece for 24 hours, take it out and observe, the metal printed circuit is bright without corrosion and discoloration, and the electrical performance of the test is not affected, indicating that the Composite glass cutting fluid is safe for OGS glass.

Embodiment 2

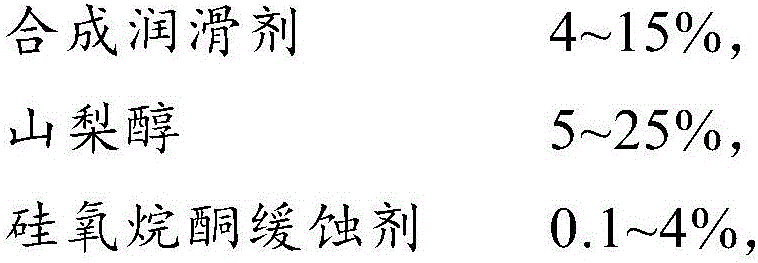

[0028] A kind of composite glass cutting fluid, the raw material composition by mass percentage is as follows:

[0029]

[0030] Heat the 5% dilution of the composite glass cutting fluid of this embodiment and keep the temperature constant at 50±2°C, soak the OGS glass workpiece for 24 hours, take it out and observe, the metal printed circuit is bright without corrosion and discoloration, and the electrical performance of the test is not affected, indicating that the Composite glass cutting fluid is safe for OGS glass.

Embodiment 3

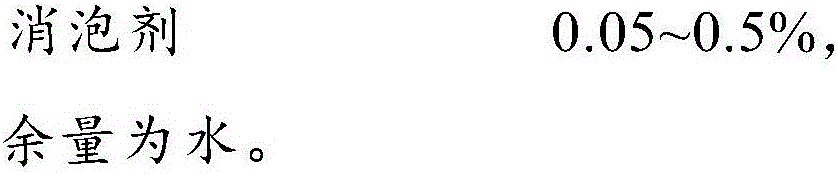

[0032] A kind of composite glass cutting fluid, the raw material composition by mass percentage is as follows:

[0033]

[0034] Heat the 5% dilution of the composite glass cutting fluid of this embodiment and keep the temperature constant at 50±2°C, soak the OGS glass workpiece for 24 hours, take it out and observe, the metal printed circuit is bright without corrosion and discoloration, and the electrical performance of the test is not affected, indicating that the Composite glass cutting fluid is safe for OGS glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com