Method for preparing strontium-doped calcium phosphate coating on surface of magnesium alloy through one-step hydrothermal method

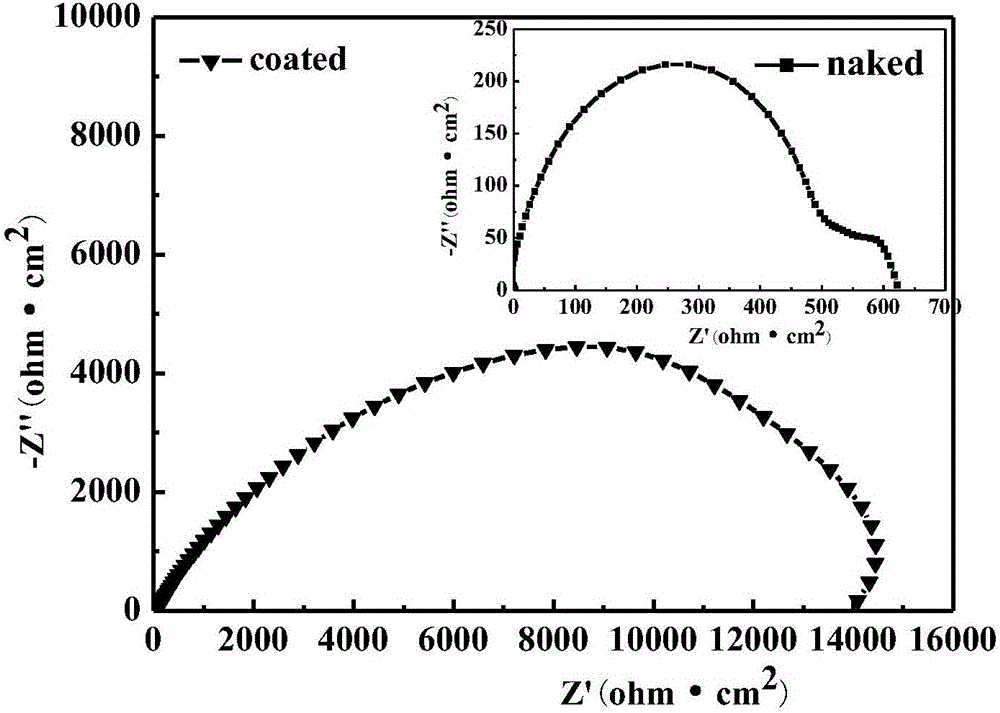

A calcium-phosphorus coating and magnesium alloy technology, which is applied in metal material coating technology, coating, medical science, etc., can solve the problems of limited substrate protection, low coating density, and low production efficiency, and achieve large Commercial promotion value, short time required, effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

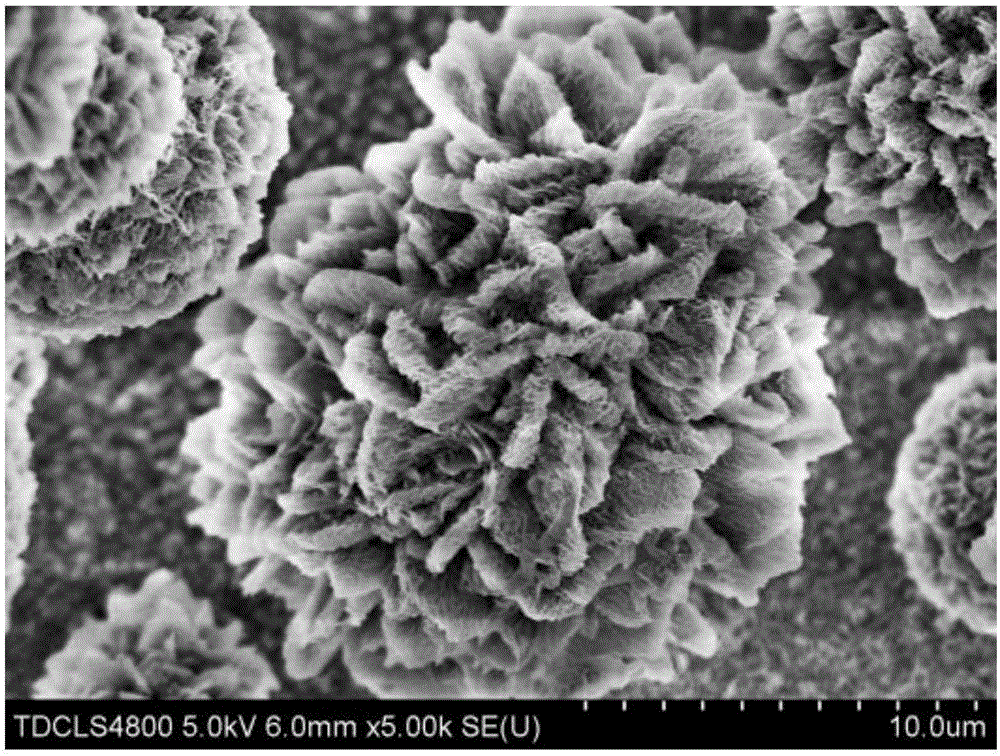

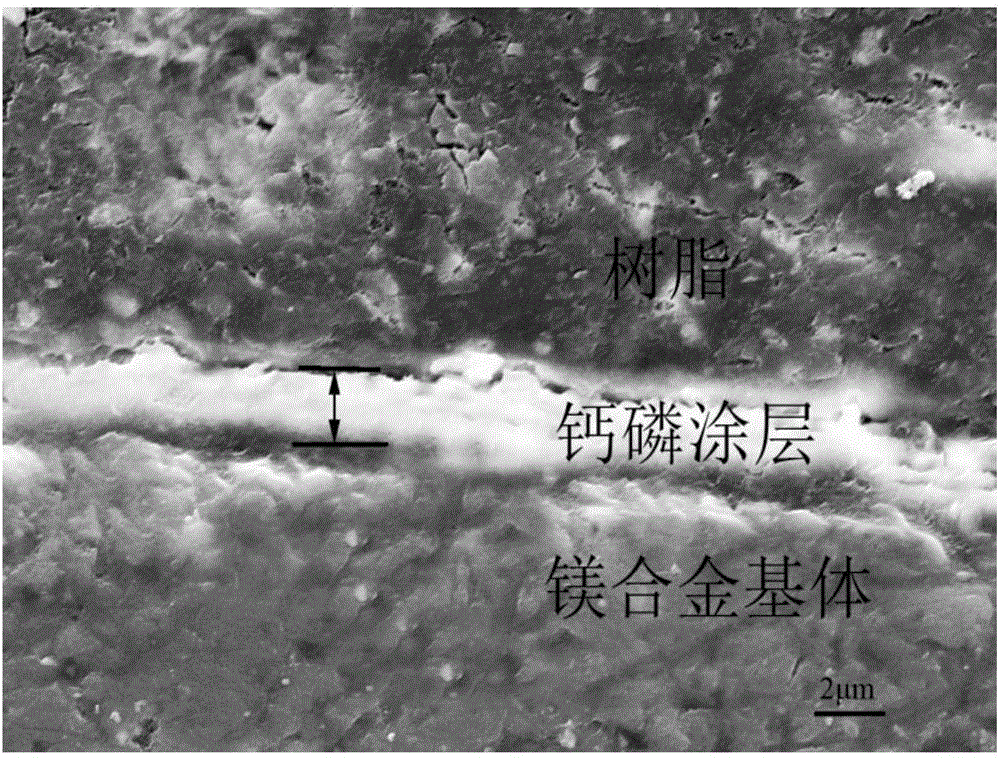

[0028] Process the AZ31 magnesium alloy into a block of 10mm×10mm×2mm, and use 600 # , 1200 # , 2000 # Polished with SiC sandpaper, then ultrasonically cleaned in acetone, deionized water, and absolute ethanol for 10 minutes, and dried with hot air. Prepare 150 mL of 3 mol / L NaOH deionized aqueous solution. Soak the polished magnesium alloy in NaOH solution at 60°C for 3 hours, then rinse the magnesium alloy sample with deionized water and dry it. With Ca(NO 3 ) 2 Prepare Ca for Ca source 2+ Aqueous solution, as Na 2 HPO 4 Preparation of PO for P source 4 3- Aqueous solution, with Sr(NO 3 ) 2 Preparation of Sr for Sr source 2+ aqueous solution. Then Sr 2+ and PO 4 3- The aqueous solution was added dropwise with Ca 2+ In the aqueous solution, finally the pH value of the mixed solution was adjusted to 6 with 20 M dilute hydrochloric acid, and stirred by magnetic force for 2 h. Among them, Ca in the mixed solution 2+ The concentration is 6mmol / L, Sr 2+ The con...

Embodiment 2

[0030] Process the AZ91 magnesium alloy into a block of 10mm×10mm×2mm, and use 600 # , 2000 # Polished with SiC sandpaper, then ultrasonically cleaned in acetone, deionized water, and ethanol for 6 minutes, and dried with hot air. Prepare 150 mL of 2 mol / L NaOH deionized aqueous solution. Soak the polished magnesium alloy in NaOH solution at 70°C for 2 hours, then rinse the magnesium alloy sample with deionized water and dry it. with CaCl 2 Prepare Ca for Ca source 2+ Aqueous solution, as NaH 2 PO 4 Preparation of PO for P source 4 3- Aqueous solution, with Sr(NO 3 ) 2 Preparation of Sr for Sr source 2+ aqueous solution. Then Sr 2+ and PO 4 3- Aqueous solution was added dropwise to Ca 2+ In the aqueous solution, the pH value of the mixed solution was finally adjusted to 5.5 with 15M dilute nitric acid, and magnetically stirred for 1.5 h. Among them, Ca in the mixed solution 2+ The concentration is 5.5mmol / L, Sr 2+ The concentration is 0.4mmol / L, PO 4 3- The...

Embodiment 3

[0032] AZ61 is used as the magnesium alloy matrix, followed by 600 # , 1200 # , 1500 # Polished with SiC sandpaper, then ultrasonically cleaned in acetone, deionized water, and ethanol for 8 minutes, and dried with hot air. Prepare 150 mL of 2 mol / L NaOH deionized aqueous solution. Soak the polished magnesium alloy in NaOH solution at 80°C for 1 hour, then rinse the magnesium alloy sample with deionized water and dry it. With Ca(CH 3 COO) 2 Prepare Ca for Ca source 2+ Aqueous solution, as NaH 2 PO 4 Preparation of PO for P source 4 3- Aqueous solution, with Sr(NO 3 ) 2 Preparation of Sr for Sr source 2+ aqueous solution. Then PO 4 3- The aqueous solution was added dropwise with Ca 2+ In the aqueous solution, the pH value of the mixed solution was finally adjusted to 6 with 5M acetic acid, and magnetically stirred for 1.5 h. Among them, Ca in the mixed solution 2+ The concentration is 5mmol / L, Sr 2+ The concentration is 0.2mmol / L, PO 4 3- The concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com