Method for preparing ceramic bond superfine abrasive polishing disk through electrophoresis codeposition

A technology of electrophoretic co-deposition and ceramic binder, applied in electrolytic coatings, coatings, etc., can solve the problems of easy agglomeration of abrasives, and achieve the effect of low cost, simple process and solving agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

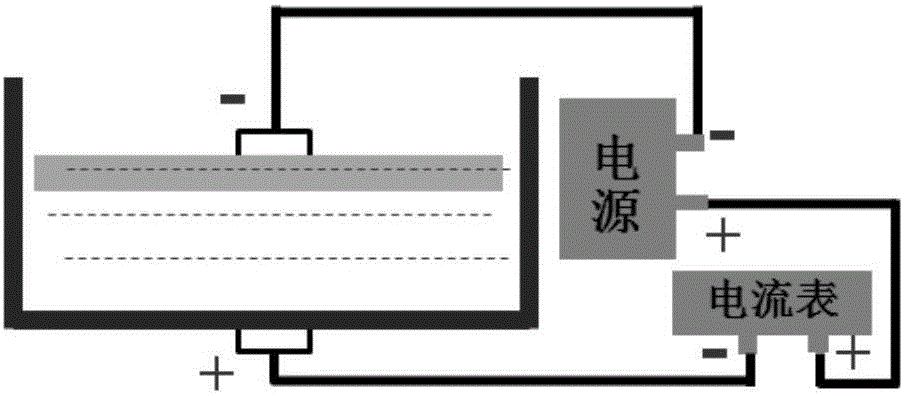

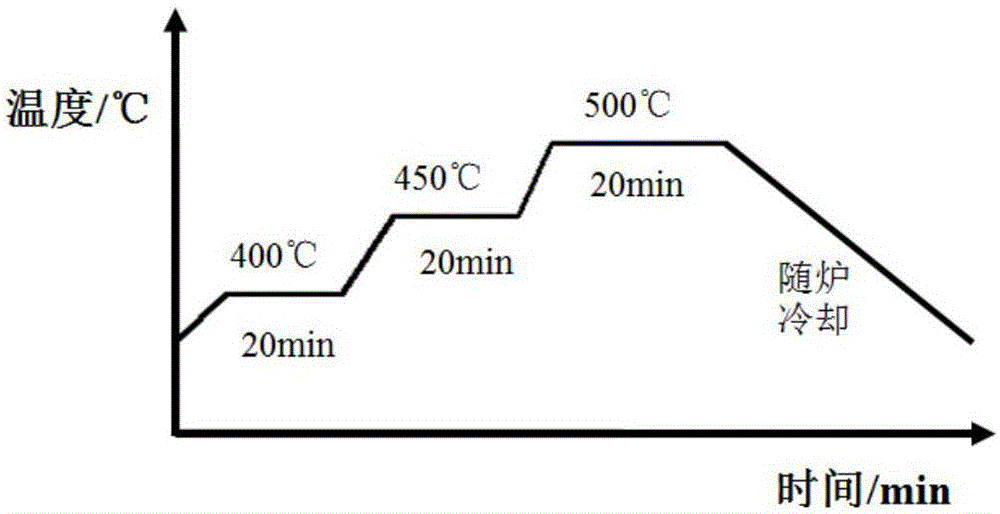

[0026] Preparation of electrophoretic co-deposited vitrified bond superfine diamond abrasive polishing disc: the abrasive concentration in the composite coating on the prepared polishing disc is preset to be 50%, and the volume ratio of prepared diamond and ceramic powder is calculated to be 1:1, suspended Liquid concentration 0.1wt%. The particle size of diamond is 100nm, and the particle size of ceramic powder is 3 solution. Magnetically stir and ultrasonically disperse the configured composite suspension for 10 minutes each to make it evenly dispersed, and then pour it into the electrophoresis tank of the self-made electrophoresis device, wherein the bottom plate of the electrophoresis tank itself is used as the anode plate, and the stainless steel substrate is used as the cathode plate, Electrophoretic co-deposition. In the experiment, the deposition voltage was selected as 50V, the distance between the plates was 2cm, and the deposition time was 10min. After the electro...

Embodiment 2

[0028] Preparation of electrophoretic co-deposited vitrified bond ultrafine alumina polishing disc: the volume ratio of alumina abrasive and ceramic powder in the prepared composite coating is preset to be 1:2, and the concentration of the suspension is 1 wt%. Alumina has a particle size of 1 μm and ceramic powder has a particle size of 3 solution. Magnetically stir and ultrasonically disperse the configured composite suspension for 10 minutes each to make it evenly dispersed, and then pour it into the electrophoresis tank of the self-made electrophoresis device, wherein the bottom plate of the electrophoresis tank itself is used as the anode plate, and the stainless steel substrate is used as the cathode plate, Electrophoretic deposition. In the experiment, the deposition voltage was selected as 40V, the distance between the plates was 1.5cm, and the deposition time was 15min. After the electrophoretic deposition was completed, the circular substrate with the deposited coati...

Embodiment 3

[0030] Preparation of electrophoretic co-deposited vitrified bond ultrafine diamond alumina mixed abrasive polishing disc: pre-set the volume ratio of diamond, alumina and ceramic powder in the prepared composite coating to 1:1:5, and the suspension concentration is 0.5wt% . The particle size of the abrasive is 600nm, and the particle size of the ceramic powder is 3 ) 3 solution. Magnetically stir and ultrasonically disperse the configured composite suspension for 10 minutes each to make it evenly dispersed, and then pour it into the electrophoresis tank of the self-made electrophoresis device, wherein the bottom plate of the electrophoresis tank itself is used as the anode plate, and the stainless steel substrate is used as the cathode plate, Electrophoretic deposition. In the experiment, the deposition voltage was selected as 60V, the distance between the plates was 2cm, and the deposition time was 20min. After the electrophoretic deposition was completed, the circular su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com