Refreshing filter paper for automobile air conditioner filter element and preparation method thereof

A technology of automobile air conditioner and filter paper, which is applied in the direction of filter paper, separation methods, chemical instruments and methods, etc., and can solve the problems of no refreshing effect and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

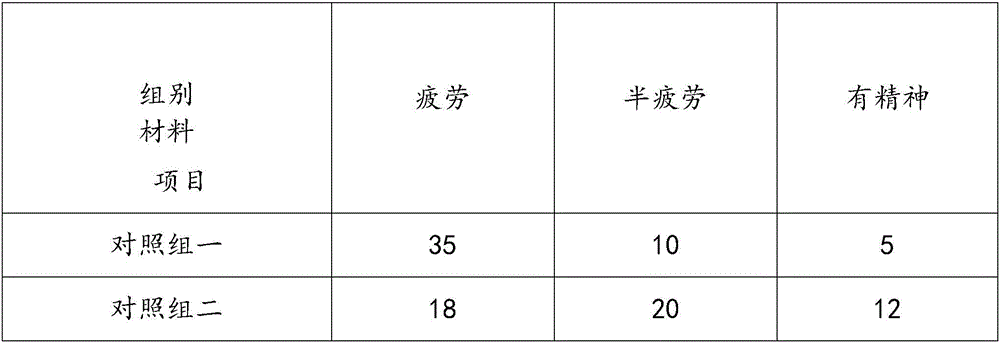

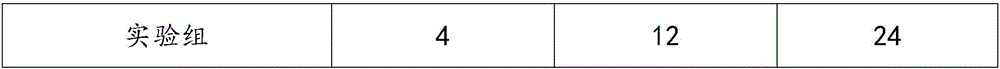

Examples

Embodiment 1

[0018] A refreshing filter paper for automobile air conditioner filter elements, made of the following materials in proportion by weight, including 60 parts of polypropylene fiber filter paper, 8 parts of epimedium, 7 parts of curculigo, 8 parts of leek seeds, and 6 parts of purple river car 13 parts of peppermint, 14 parts of Chaotianzi, 20 parts of Asparagus, 6 parts of Uncaria uncariae, 9 parts of Ligusticum edulis, 2 parts of Asparagus, 1 part of spearmint, 6 parts of Luhuo, 8 parts of Perrin , coral grass 9 parts, musk 13 parts and clove oil 15 parts.

[0019] A preparation method of refreshing filter paper for automobile air-conditioning filter element, comprising the following steps:

[0020] 1) Put 60 parts of polypropylene fiber filter paper into a drying oven, keep the heating temperature at 55-58°C and dry for 16-18 minutes for later use;

[0021] 2) Mix 8 parts of Epimedium, 7 parts of Curculigo, 8 parts of Chive Seed, 6 parts of Ziheche, 13 parts of Mint, 14 part...

Embodiment 2

[0026] A refreshing filter paper for automobile air conditioner filter elements, made of the following materials in parts by weight, including 62.5 parts of polypropylene fiber filter paper, 9 parts of epimedium, 9 parts of curculigo, 11 parts of chive seeds, and 10 parts of purple river car 15.5 parts of peppermint, 16.5 parts of Astragalus, 20.5 parts of Asparagus, 6.5 parts of Uncaria, 11.5 parts of Ligusticum edulis, 3.5 parts of Asparagus, 2.5 parts of Spearmint, 7.5 parts of Deerweed, 11 parts of Perrin , coral grass 11.5 parts, musk 14 parts and clove oil 17.5 parts.

[0027] A preparation method of refreshing filter paper for automobile air-conditioning filter element, comprising the following steps:

[0028] 1) Put 62.5 parts of polypropylene fiber filter paper into a drying oven, keep the heating temperature at 55-58°C and dry for 16-18 minutes for later use;

[0029] 2) Take 9 parts of Epimedium, 9 parts of Curculigo, 11 parts of Chive Seed, 10 parts of Ziheche, 15...

Embodiment 3

[0034] A refreshing filter paper for automobile air conditioner filter elements, made of the following materials in proportion by weight, including 65 parts of polypropylene fiber filter paper, 10 parts of epimedium, 11 parts of curculigo, 14 parts of chive seeds, and 14 parts of Ziheche 18 parts of peppermint, 19 parts of Chaotianzi, 21 parts of Asparagus, 7 parts of Uncaria uncariae, 14 parts of Ligusticum edulis, 5 parts of Asparagus, 4 parts of spearmint, 9 parts of deerwort, 14 parts of Perrin , 14 parts of coral grass, 15 parts of musk and 20 parts of clove oil.

[0035] A preparation method of refreshing filter paper for automobile air-conditioning filter element, comprising the following steps:

[0036] 1) Put 65 parts of polypropylene fiber filter paper into a drying oven, keep the heating temperature at 55-58°C and dry for 16-18 minutes for later use;

[0037] 2) Take 10 parts of Epimedium, 11 parts of Curculigo, 14 parts of Chive Seed, 14 parts of Ziheche, 18 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com