Coal mine underground acoustic wave transmission device and method

A technology of a transmission device and a transmission method, which is applied in the field of mining drilling instruments, can solve the problems of increasing the difficulty of orifice signal demodulation, the possibility of realization is small, and the signal frequency is high, so as to improve battery utilization efficiency and reduce signal attenuation , The effect of extending the transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

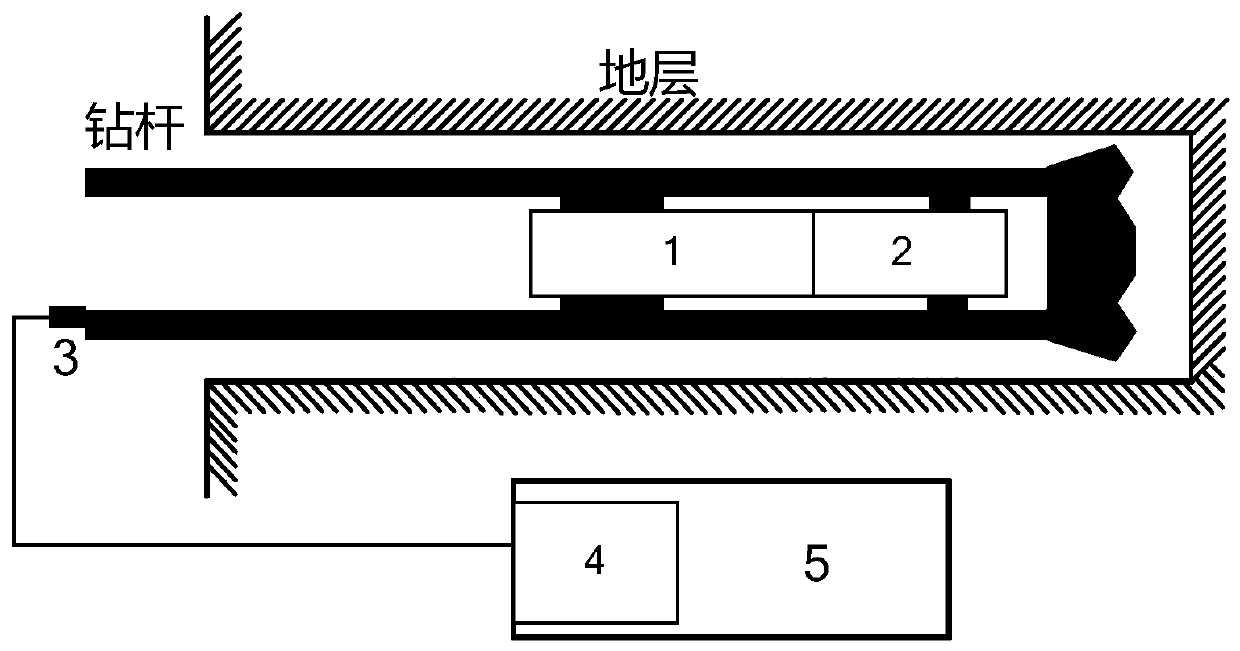

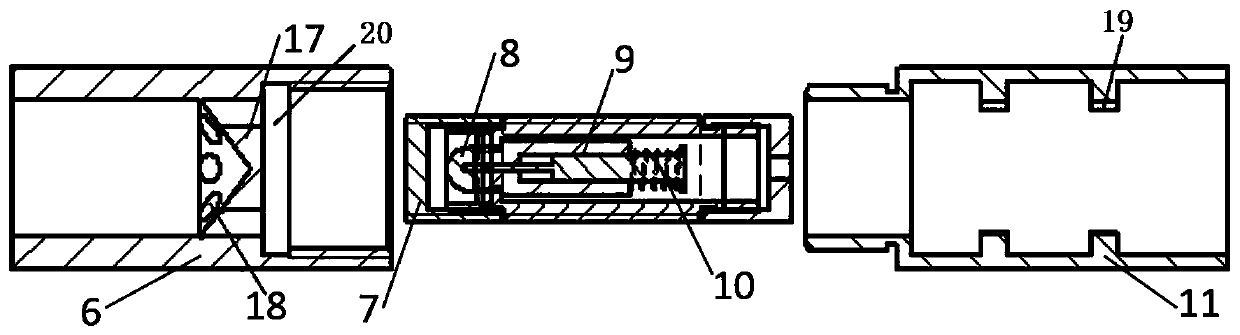

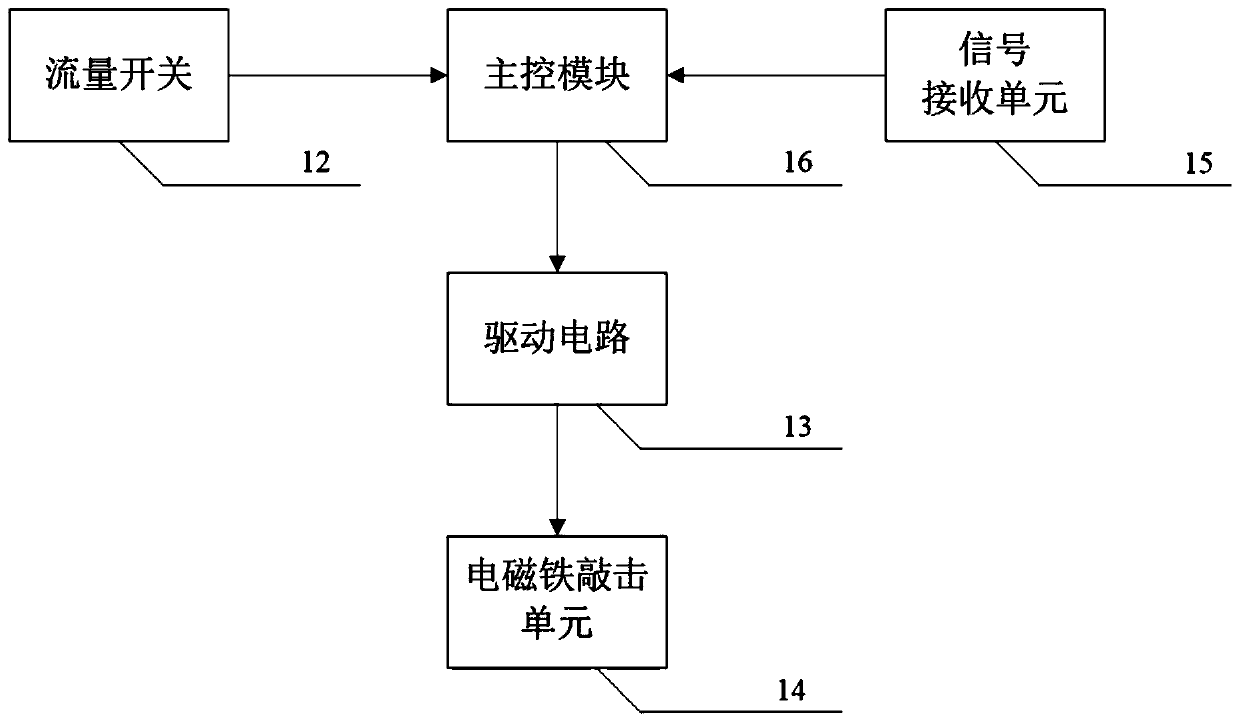

[0033] see figure 1 , The mining acoustic wave measurement while drilling system consists of a data percussion sending module 1, a sensor group 2, an orifice sensor 3, a data decoding module 4 and a computer 5, all of which are explosion-proof designed and can be used in explosive gas environments in coal mines. When the measurement data is uploaded while drilling, the sensor group 2 sends the collected engineering parameters inclination angle, azimuth angle and tool face angle to the data knocking sending module 1, and the data knocking sending module 1 compresses and encodes the engineering parameters into binary codes, and transmits them through the coil The sound wave signal generated by driving the iron core to strike the explosion-proof shell of the instrument sends out the binary code, and the sound wave signal is transmitted to the orifice along with the drill pipe body, received by the orifice sensor 3 and converted into an electrical signal, and then transmitted to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com