Method and device for anti-freezing and heat preservation of alkali-adding pipelines in plateau wastewater treatment systems

A technology for waste water treatment system and horizontal pipeline, applied in pipeline heating/cooling, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of inability to meet heat tracing requirements, high cost of use, short service life, etc., and achieve savings Heat tracing source, low cost, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The content of the present invention will be described below in conjunction with specific embodiments, so that those skilled in the art can further understand the present invention. It should be noted that the present invention is not limited to the following examples.

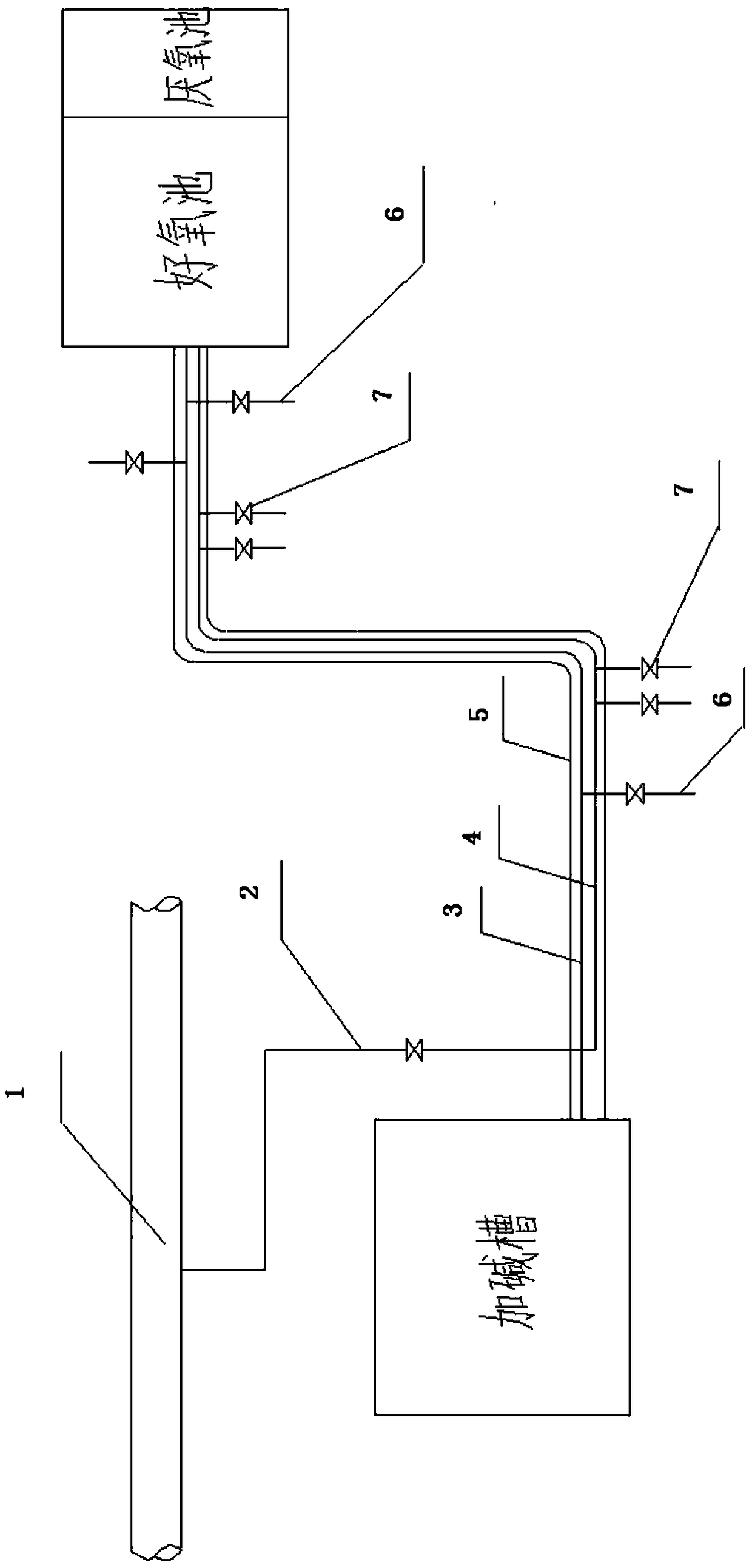

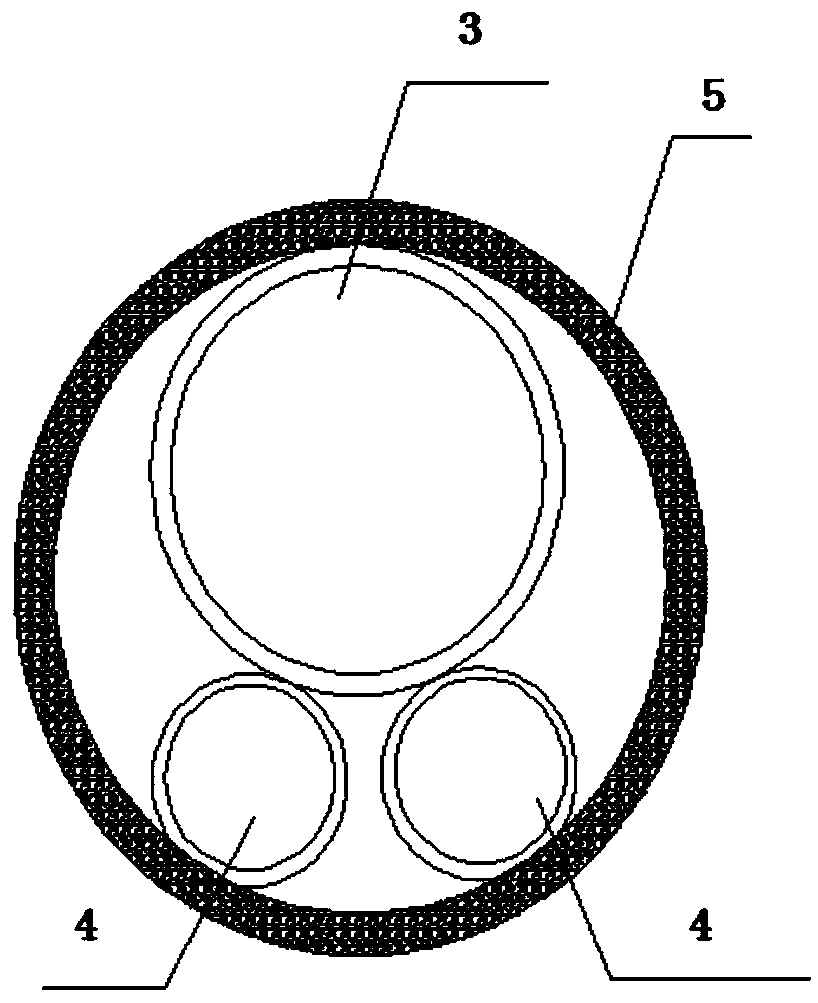

[0024] A method for anti-freezing and heat preservation of alkali-adding pipelines in a plateau wastewater treatment system. A steam-tracing pipeline is led out from the steam waste heat main pipe, and the steam-tracing pipeline is close to the outer wall of the alkali-adding pipeline, and the steam-tracing pipeline and the alkali-adding pipeline are bundled together ;During the process of pumping the lye to the aerobic pool, the heat is transferred to the lye through the steam waste heat transfer, and the temperature of the liquid alkali will not kill the microorganisms in the wastewater treatment system, so as to realize the antifreeze and heat preservation of the alkali addition pipeline of the platea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com