Technological method and system for producing freshwater fish feed by using kitchen waste

The technology of a kitchen waste and a process method is applied in the field of resource recycling of kitchen waste, which can solve the problems of less resource utilization and the like, and achieve the effects of low fat content, low salt content, and increased fermentation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

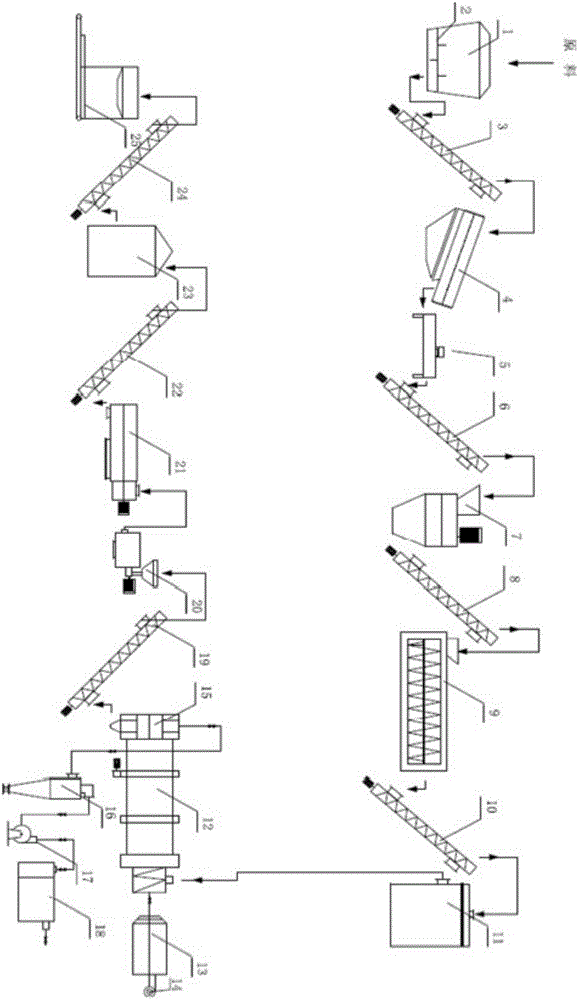

[0027] Below in conjunction with accompanying drawing, the processing method of the present invention for producing freshwater fish feed from food waste will be described in detail.

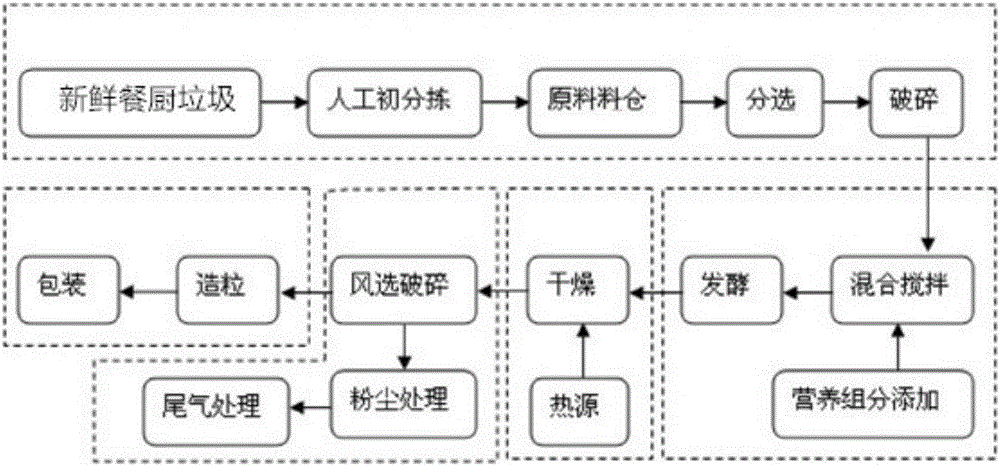

[0028] Such as figure 1 Shown, the operation of food waste production freshwater fish feed of the present invention mainly comprises five major operations:

[0029] Process 101: sorting and crushing process. Fresh kitchen waste from canteens and restaurants is manually sorted to remove impurities such as wood, bamboo, plastic, and metal, and is collected and stored in the storage silo. The garbage is transported from the storage silo to the roller screen by a screw conveyor to further remove impurities. Then it is transported to the crusher by the screw conveying device and crushed into clean kitchen waste with a particle size of ≤30mm.

[0030] First of all, guide the staff in the canteens of schools, enterprises and institutions to roughly classify the kitchen waste, and remove large debris s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com