Preparation method of enhanced chlorinated polyvinyl chloride hollow fiber membrane

A technology of chlorinated polyvinyl chloride and fiber membrane, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as broken wires and degraded effluent water quality, and achieve reduced process costs, low prices, and solutions The effect of easy wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

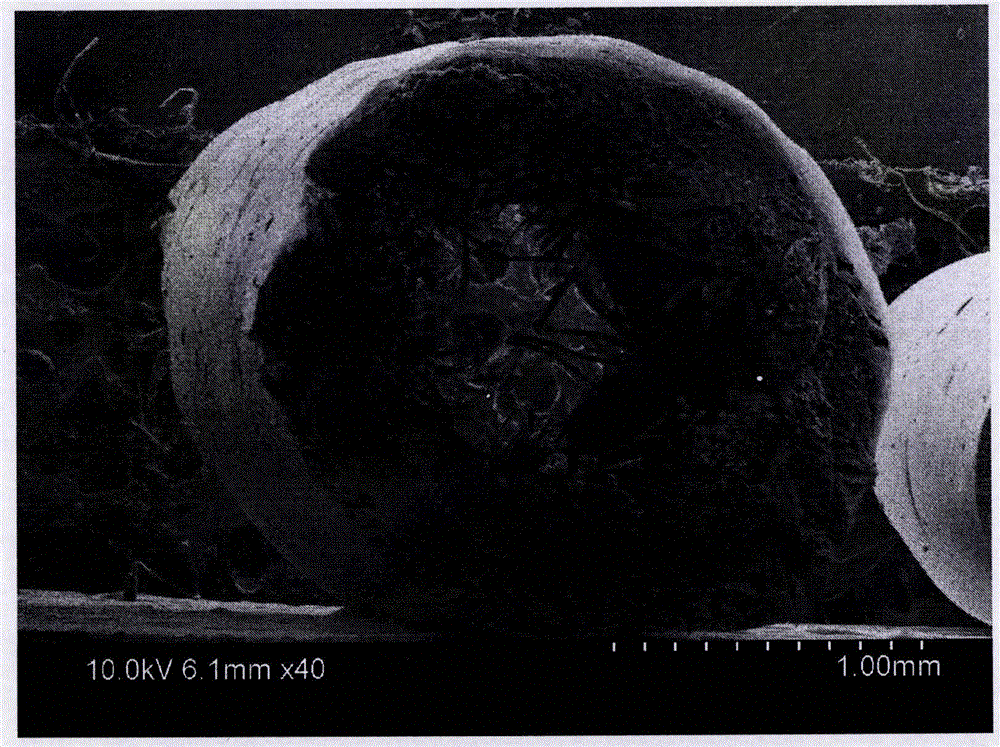

[0023] (1) A two-dimensional braiding machine is used to weave CPVC filaments into a CPVC hollow braided tube with a diameter of 1.4 mm.

[0024] (2) 20wt% CPVC (weight average molecular weight is 160000 Daltons, chlorine content is 64.5%), 17wt% polyethylene glycol and 2wt% methyltin maleic anhydride are dissolved in 61wt% at 65°C In the N,N-dimethylformamide, after stirring and vacuum defoaming for 24 hours, the CPVC casting solution was obtained.

[0025] (3) Adopt co-extrusion composite spinning process, the hollow braided pipe that step (1) obtains and the CPVC cast film solution that step (2) obtains are co-extruded through annular spinneret, and make described cast film solution uniform coated on the surface of the hollow braided tube, after a 10 cm dry spinning process, immersed in water at 50° C., and fully cured, the reinforced CPVC hollow fiber membrane was obtained.

[0026] After testing, the obtained reinforced CPVC hollow fiber membrane has a diameter of 2.0mm ...

Embodiment 2

[0028] (1) A two-dimensional braiding machine is used to weave CPVC filaments into a CPVC hollow braided tube with a diameter of 1.4 mm.

[0029] (2) 20wt% CPVC (weight average molecular weight is 160000 Daltons, chlorine content is 64.5%), 17wt% polyethylene glycol and 2wt% methyltin maleic anhydride are dissolved in 61wt% at 65°C In the N,N-dimethylformamide, after stirring and vacuum defoaming for 24 hours, the CPVC casting solution was obtained.

[0030] (3) Use γ-methacryloxypropyltrimethoxysilane (KH570) to infiltrate the hollow fiber tube prepared in step (1), so that the outer surface of the hollow braided tube is fully infiltrated, and the infiltration time is 0.5h*

[0031] (4) Adopt co-extrusion composite spinning process, the hollow braided pipe that step (3) obtains and the CPVC cast film liquid that step (2) obtains are co-extruded through annular spinneret, and make described cast film liquid evenly coated on the surface of the hollow braided tube, after a 10 c...

Embodiment 3

[0034] (1) A two-dimensional braiding machine is used to weave CPVC filaments into a CPVC hollow braided tube with a diameter of 1.6 mm.

[0035](2) 20wt% CPVC (weight average molecular weight is 160000 Daltons, chlorine content is 64.5%), 17wt% polyethylene glycol and 2wt% methyltin maleic anhydride are dissolved in 61wt% at 65°C In the N,N-dimethylformamide, after stirring and vacuum defoaming for 24 hours, the CPVC casting solution was obtained.

[0036] (3) Adopt co-extrusion composite spinning process, the hollow braided pipe that step (1) obtains and the CPVC cast film solution that step (2) obtains are co-extruded through annular spinneret, and make described cast film solution uniform coated on the surface of the hollow braided tube, after a 10 cm dry spinning process, immersed in water at 50° C., and fully cured, the reinforced CPVC hollow fiber membrane was obtained.

[0037] After testing, the obtained reinforced CPVC hollow fiber membrane has a diameter of 2.2mm a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com