Mesoporous activated carbon/titanium dioxide photocatalyst for degrading colored sewage and preparation method and application thereof

A technology of mesoporous activated carbon and titanium dioxide, which is used in physical/chemical process catalysts, water/sewage treatment equipment, catalyst carriers, etc., can solve the problems of low efficiency, difficult recovery and high cost, improve economy and enhance photocatalytic efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

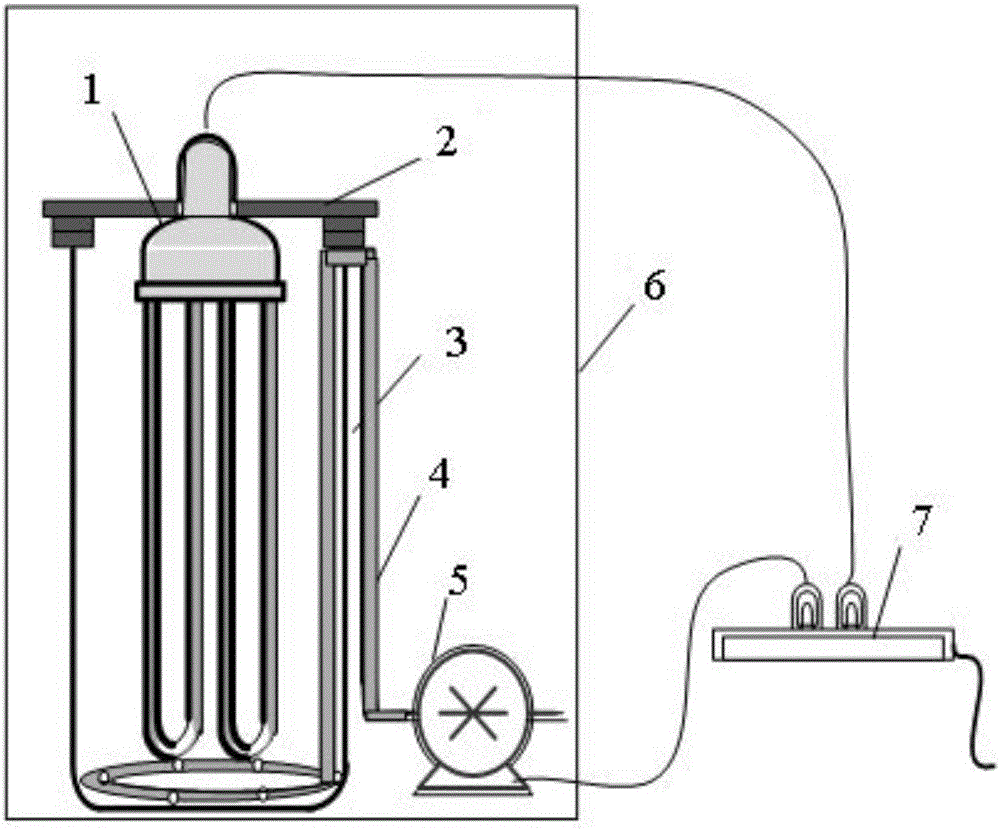

[0058] (1) Carbonization and activation of raw materials: The raw materials are mainly camellia oleifera shells. The carbonization / activation integrated muffle furnace designed by our laboratory is used for carbonization / activation experiments. Nitrogen and water vapor are introduced during the activation process, and the flow rates of steam are 0.3mL / min, 0.5mL / min, activated carbon with different specific surface and pore structure can be obtained.

[0059] (2) The activated carbon prepared in step (1) with a steam flow rate of 0.3 mL / min was pretreated differently from the purchased commercial bamboo activated carbon. Type A: Take 20.0g of biomass activated carbon in a beaker, add 1mol / L NaOH solution, soak for 30min, filter, and rinse with deionized water for 3 times. Add about 8% HNO to the rinsed and filtered activated carbon 3 (Add 20mL65%~68%HNO from 140mL water 3 Prepared), boiled for 1h. Suction filtration, and wash with deionized water until neutral, put into ove...

Embodiment 2

[0068] (1) The pretreated bamboo charcoal was loaded with titanium dioxide by the sol-gel method, and calcined by temperature programming in tube furnaces at 400°C, 500°C, and 600°C, respectively. From the XRD pattern ( Figure 4 ) It can also be seen that with the increase of calcination temperature, the crystal form of anatase gradually becomes perfect and sharp, and the grain size increases rapidly at the same time.

[0069] (2) The calcined catalyst was subjected to photocatalytic experiments under the same conditions to explore the influence of different calcination temperatures on the photocatalytic effect of the catalyst. Through experiments, it is possible to establish an image of the degradation of methylene blue solution (indicated by solution concentration) at different calcination temperatures over time, such as Figure 5 .

[0070] pass Figure 5 It can be seen that the calcination temperature of 500°C has the best catalytic performance. By experiment, get F...

Embodiment 3

[0072] (1) Methylene blue is prepared into a solution of 30 mg / L, and other experimental conditions remain unchanged;

[0073] (2) Investigating different amounts of bamboo charcoal / TiO 2 (Calcination at 500°C) Effect of photocatalyst on degradation rate at different time periods. Photocatalyst refers to: sample 4-500, that is, calcined bamboo charcoal / TiO at 500°C 2 .

[0074] Depend on Figure 6 It can be seen that at the same concentration of the reaction solution, the higher the concentration of the reaction catalyst in the solution, the higher the adsorption efficiency and photodegradation efficiency. At the same time, when the amount of catalyst added is 2g / L, the degradation efficiency is basically twice that of 1g / L. However, if the catalyst reaction concentration continues to increase at this time, the photodegradation effect does not increase by multiples but increases very slowly. Therefore, it is the best choice to add a catalyst amount of 2g / L to the actual 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com