Continuous screen printing machine for ceramic substrate and printing method thereof

A technology for screen printing machines and ceramic substrates, which is applied in screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of inability to cure printing materials, brittle ceramic films, and inability to directly obtain finished substrates, etc. Productivity, the effect of reducing electrical resistance and thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the objects, technical solutions and advantages of the present invention more clear and understandable, the present invention will be described below in conjunction with exemplary embodiments and with reference to the accompanying drawings.

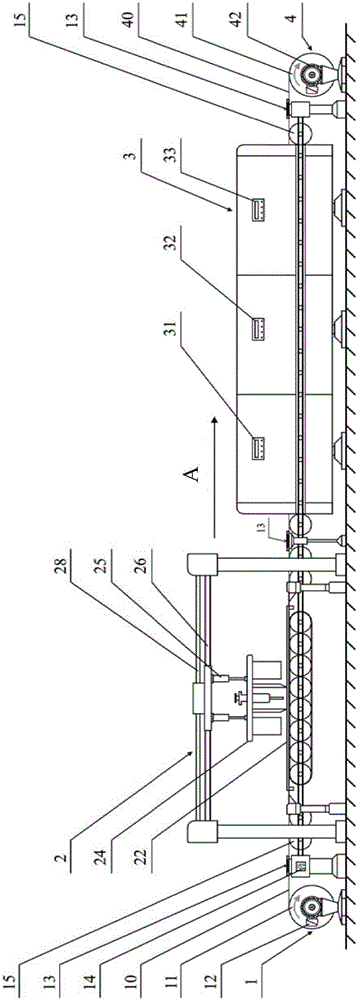

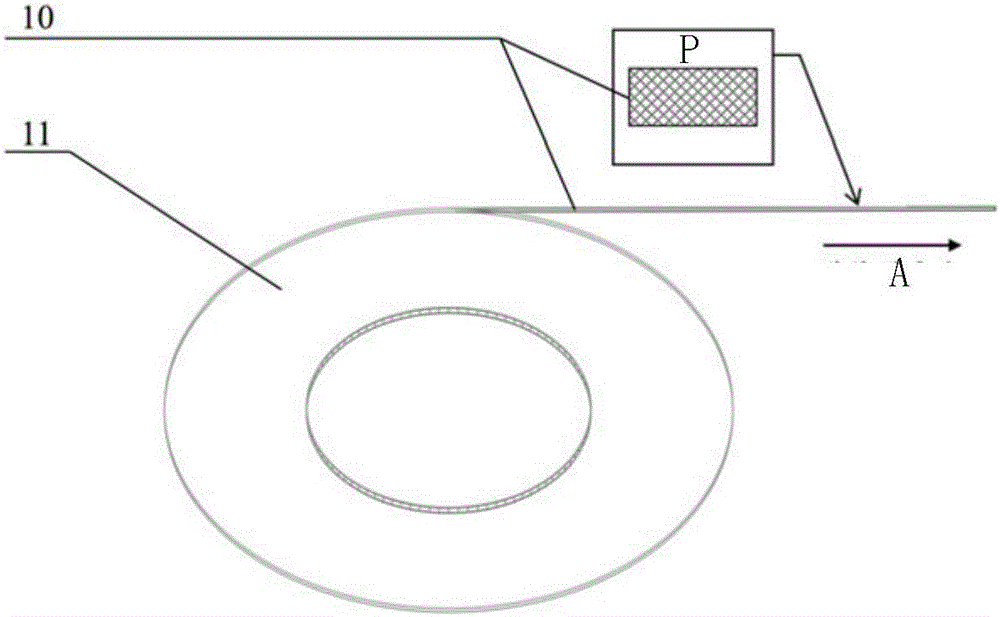

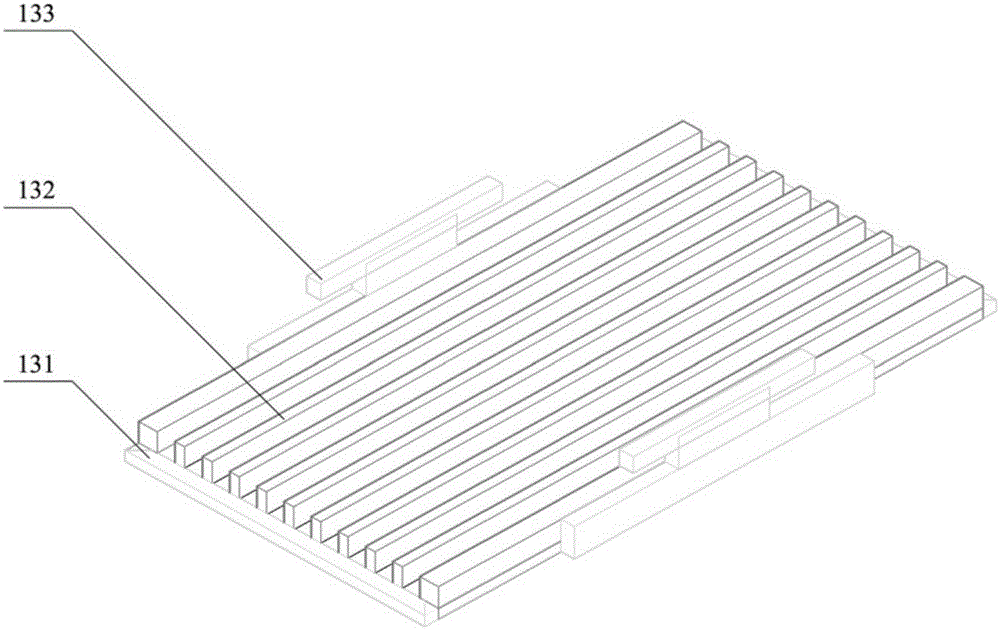

[0038] This screen printing machine provided by the invention, such as figure 1 As shown, it includes: a film feeding system 1 , a printing system 2 , a heat treatment system 3 , and a substrate film collecting system 4 . In the film feeding system 1, it includes the silicon carbide ceramic film 10 to be printed circuit, the horizontal motor 12 that drives the silicon carbide ceramic film reel 11 to rotate, the positioning mechanism 13 for determining the position where the film 10 enters the printing system 2, and drives The transmission mechanism 14 that the film 10 advances and the stainless steel roller 15 with a rough surface. The printing system 2 mainly includes a film template 22, a scraper device 24, a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com