A method for constructing anode biofilm of microbial electrochemical system

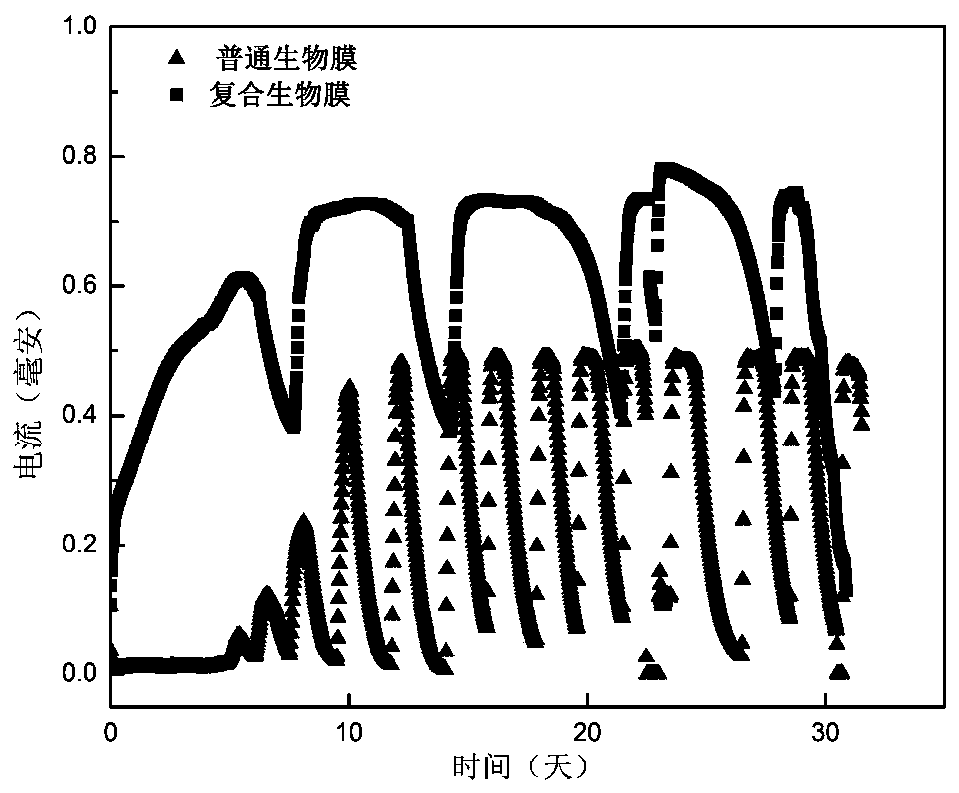

A microbial electrochemistry, biofilm technology, applied in the fields of electrochemical biocombination treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem that the improvement of anode biofilm performance will be limited and increase the uncertainty of successful anode startup. , can not guarantee the quality of the inoculum and other problems, to achieve the effect of improving the electron transfer and substrate transfer capacity, omitting the domestication culture stage, and shortening the start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1. Directional expansion of electrochemically active bacteria. Collect the microbial sample on the anode in the bioelectrochemical reactor that has been in stable operation as the source of bacteria for inoculation, inoculate it in the LB medium Erlenmeyer flask containing 25g / L, feed nitrogen for 30min to create an anaerobic environment, then seal it, Under anaerobic conditions, culture was carried out on a shaker with a rotation speed of 150 rpm and a temperature of 30° C. for 24 hours.

[0026] Step 2, mixing and immobilizing the multi-walled carbon nanotubes and electrochemically active bacteria. Prepare multi-walled carbon nanotube solution, ultrasonically disperse for 30 minutes, then absorb 2mL of 6g / L multi-walled carbon nanotube solution into 25mL of electrochemically active bacteria solution, shake well, and let stand for 3 hours.

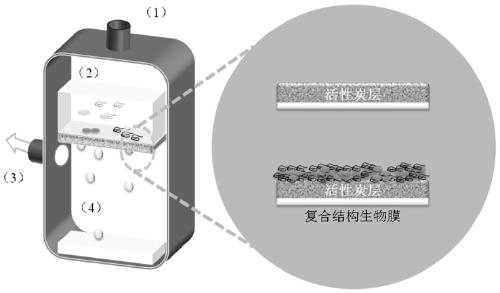

[0027] Step 3: Filtration and immobilization of the composite structure biofilm on the surface of the anode.

[0028] Amon...

Embodiment 2

[0032] Step 1. Directional expansion of electrochemically active bacteria. Collect the microbial sample on the anode in the bioelectrochemical reactor that has been in stable operation as the source of bacteria for inoculation, inoculate it in an LB medium Erlenmeyer flask containing 30g / L, feed nitrogen for 30min to create an anaerobic environment, and then seal it. Under anaerobic conditions, culture was carried out on a shaker with a rotation speed of 150 rpm and a temperature of 30° C. for 24 hours.

[0033] Step 2, mixing and immobilizing graphene and electrochemically active bacteria. Prepare graphene solution, ultrasonically disperse for 30 minutes, then absorb 2mL8g / L graphene solution and add it to 25mL electrochemically active bacteria solution, shake well, and let stand for 3 hours.

[0034] Step 3: Filtration and immobilization of the composite structure biofilm on the surface of the anode.

[0035] Among them, the first step is to prepare the filter-type activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com