Ecological concrete

A technology of ecological concrete and aggregate, applied in the field of ecological concrete, can solve the problems of resource shortage, water pollution, direct rainwater discharge, etc., and achieve the effect of efficient collection, purification, treatment, recycling, protection of ecological environment, and resource conservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

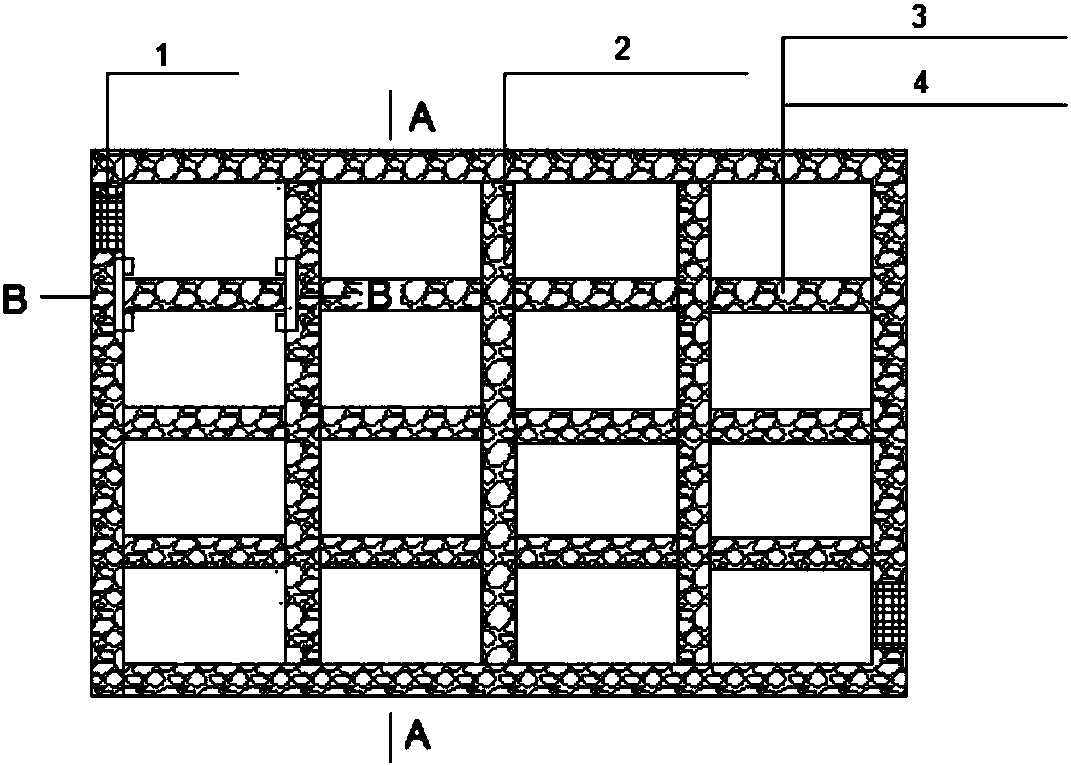

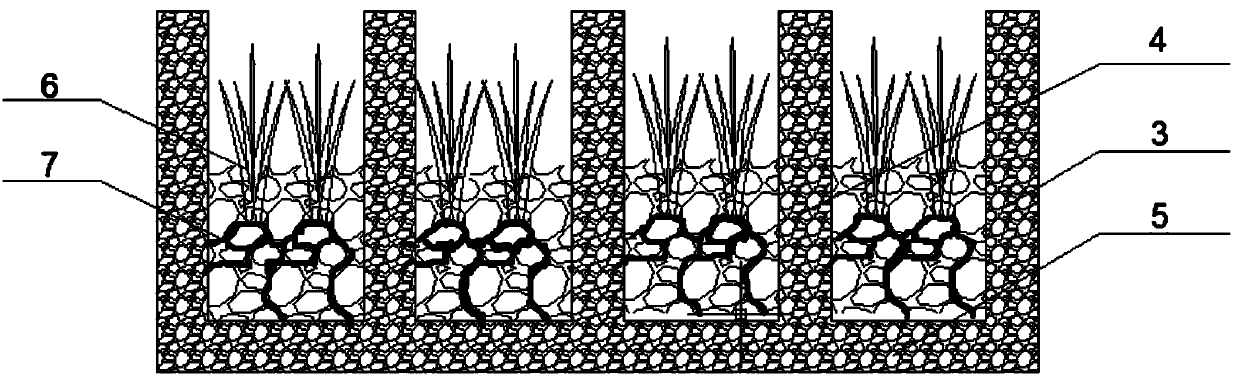

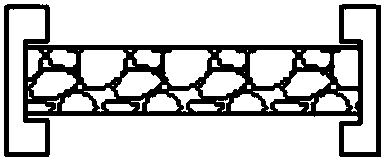

[0023] For further describing the present invention, now in conjunction with accompanying drawing, do following description:

[0024] An ecological concrete comprises 1400-1500Kg of aggregate, 150-300Kg of sand, 250Kg of cement, 5L of admixture and 67.5-110L of water. The cement is P·O 42.5 grade ordinary Portland cement; the sand is natural river sand with a fineness modulus of 2.46 and a bulk density of 1480kg / m 3 ; The aggregate is processed from natural stone, and the particle size of the aggregate is 5-16.5mm. The admixture is composed of materials in parts by weight, 5-10 parts of calcium carbonate, 40-50 parts of silica powder, 5-8 parts of lignin sulfuric acid, 1-3 parts of early strength agent, 0.3-0.4 parts of water-retaining agent, air-entraining Among them, the early strength agent is sodium nitrite, the water reducer is polycarboxylate ether high-efficiency water reducer; the water retaining agent is polyacrylamide; the air-entraining agent is sodium dodecylbenze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com