Polypropylene fiber-reinforced alkali slag cementing material

A technology of polypropylene fiber and cementitious materials, which is applied in the field of polypropylene fiber reinforced alkali slag cementitious materials, and can solve the problems of high brittleness and high brittleness of alkali slag cementitious materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

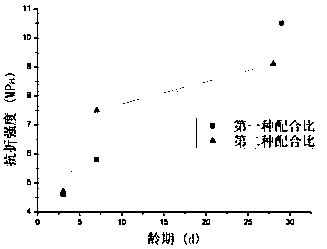

Examples

Embodiment 1

[0028] A polypropylene fiber reinforced alkali slag cementitious material and a preparation method thereof, the method comprising the steps of:

[0029] (1) Raw materials and ratio:

[0030] The main chemical components of slag are: silicon dioxide 36.9%, aluminum oxide 15.66%, calcium oxide 37.57%, magnesium oxide 9.3%, iron oxide 0.36%. The main activity indicators are: the quality coefficient is 1.69, the alkalinity coefficient is 0.97, and the activity coefficient is 0.42. This test mainly uses potassium silicate with two moduli of M=1.0 and M=2.0, sodium hydroxide with a mass fraction ≥96.0%, polypropylene fiber with an elastic modulus of 42GPa, and tap water.

[0031] (2) Determine the size of the test piece for testing:

[0032] A compressive and flexural specimen of 40mm×40mm×160mm is used, and a specimen of 40mm×40mm×160mm is used for the flexural test, and the compressive strength of the specimen is measured after the specimen is broken.

[0033] Cubic compressive...

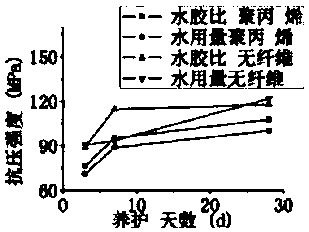

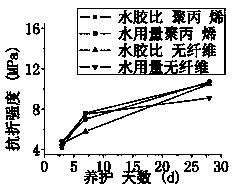

Embodiment 2

[0039] The main parameters of potassium silicate are shown in Table 1, and the mixing ratio parameters of alkali slag cementitious materials are shown in Table 2.

[0040] Table 1 Main parameters of potassium silicate

[0041]

[0042] Water glass parameter

[0043] Table 2 Mixing ratio of alkali slag cementitious material

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com