Method for making biological fertilizer by utilizing livestock and poultry waste

A technology of livestock and poultry manure and manure, which is applied in the field of biological fertilizer production from livestock and poultry manure, can solve pollution and other problems, and achieve the effect of easy production, good effect and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

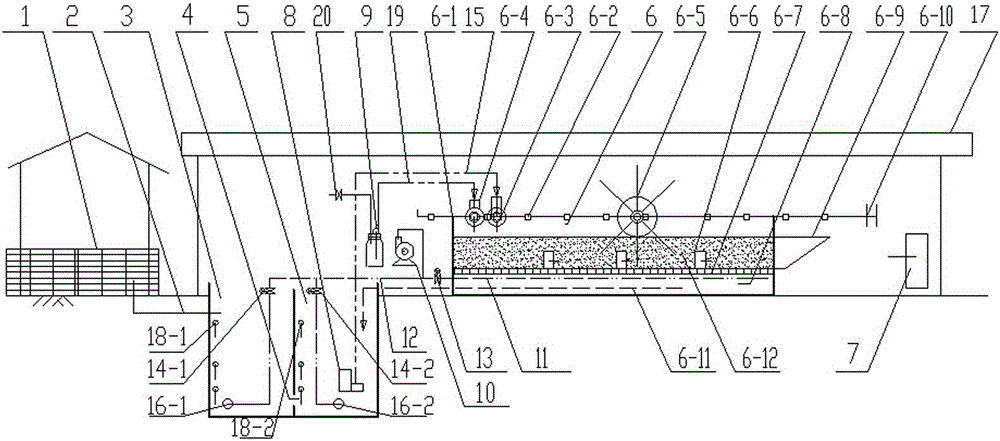

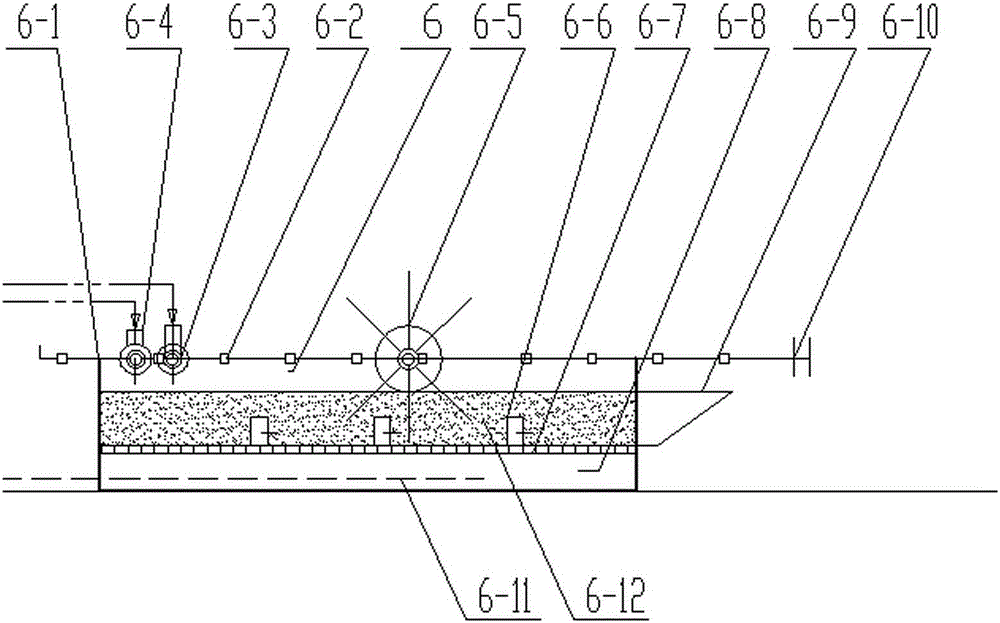

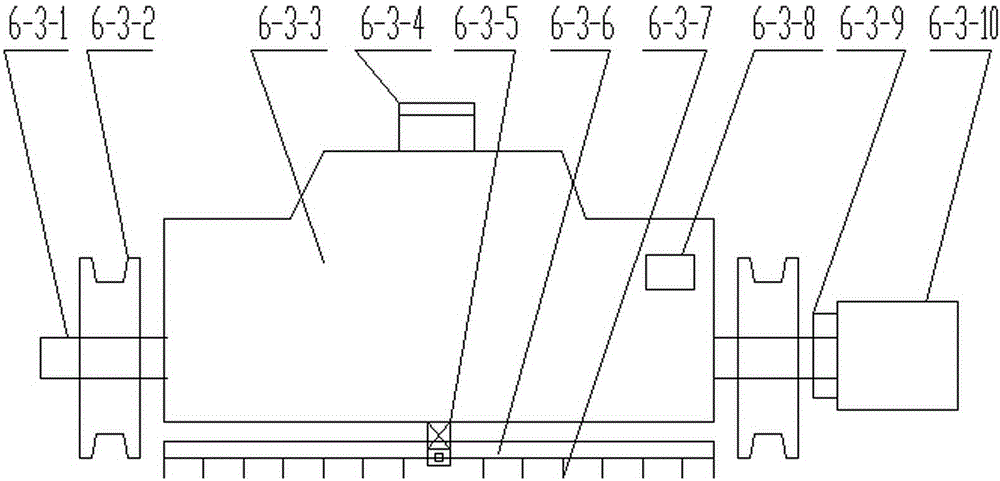

Method used

Image

Examples

Embodiment 1

[0028] A 100-head pig farm in Zhengzhou City produces about 2000kg of feces every day. Two septic tanks have been built in the farm area, and the size of each tank is 5000x3000x2000mm. We installed a liquid level controller in the pool, the height limit is 15000mm, and the actual volume of a single pool is 22.5m 3 , Change one of the two septic tanks into a biochemical hydrolysis tank, and install air ducts and wind jets in the tanks. Next to the biochemical hydrolysis tank, we installed a set of livestock and poultry manure bio-fertilization device with an overall size of 6000x2500x1500mm. In the device, we laid 1 meter thick crushed corn straw and wheat straw at a ratio of 1:1, with a total volume of about 15m 3 . After the fan installed on the livestock and poultry manure biological fertilizer plant is started, the manure in the two ponds is fully stirred through the air duct and the wind jet, and the measured solid-liquid ratio is 1:52. According to the ratio of crushed ...

Embodiment 2

[0033] In a dairy farm with 100 cows in the southern suburb of Jiyuan City, the daily manure production is about 3000kg, and there are four 4000x3000x2000mm manure collection tanks connected together. We selected two pools to transform into a fecal storage pool and a biochemical hydrolysis pool, and installed liquid level controllers in the pools respectively, with a height limit of 15000mm and an actual volume of 18m 3 , A set of 6000x2500x1500mm livestock and poultry manure biological fertilizer device was installed next to the biochemical hydrolysis tank, and 0.8 meters thick crushed crop straw was laid in the device, with a total amount of about 12m 3 . Start the PLC controller, fully stir the manure in the manure storage tank and biochemical hydrolysis tank according to the set program, and the solid-liquid ratio test in the laboratory is 1:4.8. According to the ratio of 6:4 of crushed crop straw and manure, the submersible sewage pump is used to extract 8 m of waste wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com