Linear temperature-sensitive polyurethane and preparation method thereof

A polyurethane and temperature-sensitive technology, applied in the field of linear temperature-sensitive polyurethane and its preparation, can solve the problems of complex synthesis method and high production cost, and achieve the effects of simple synthesis method, cost saving and good temperature-sensitive effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

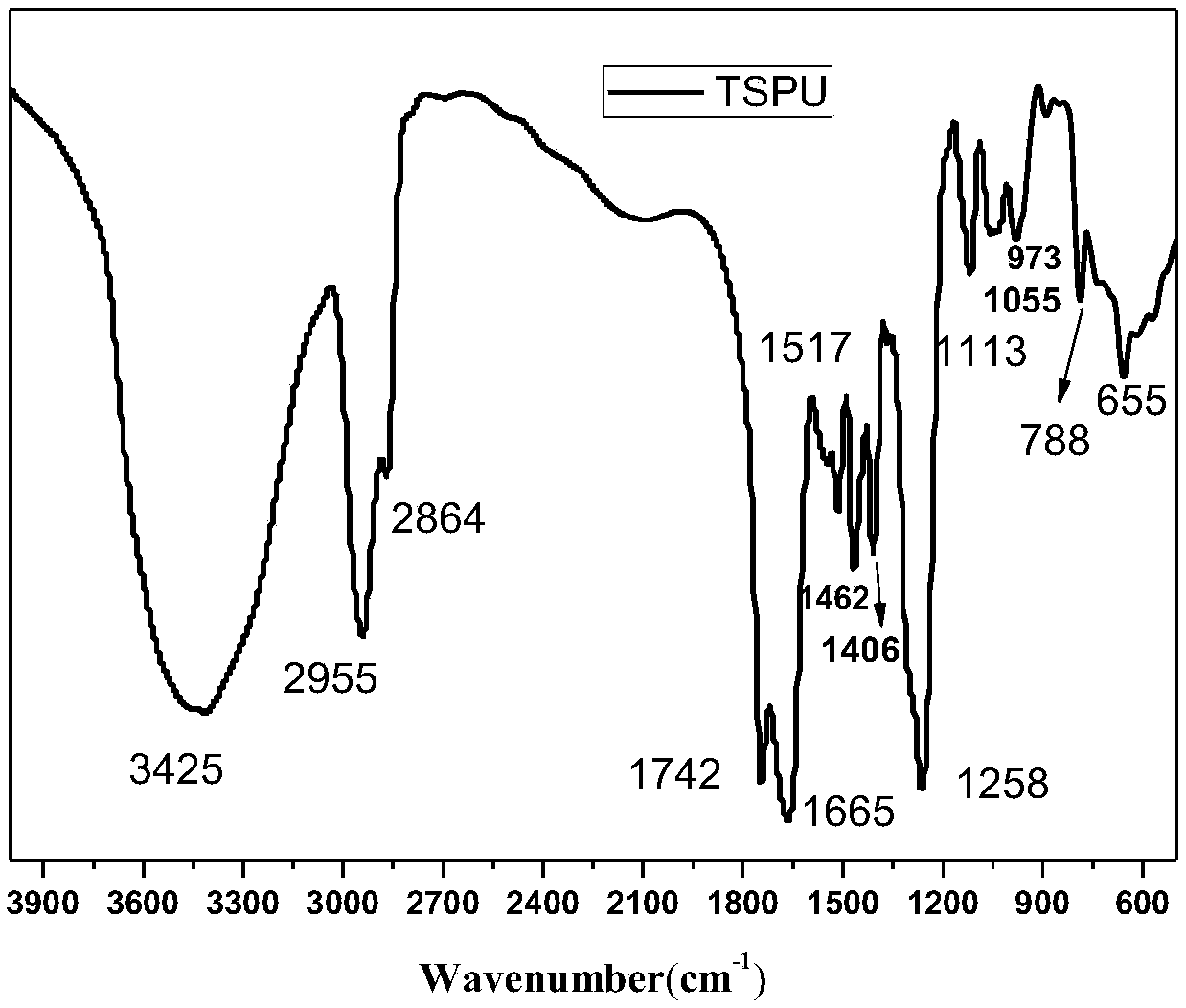

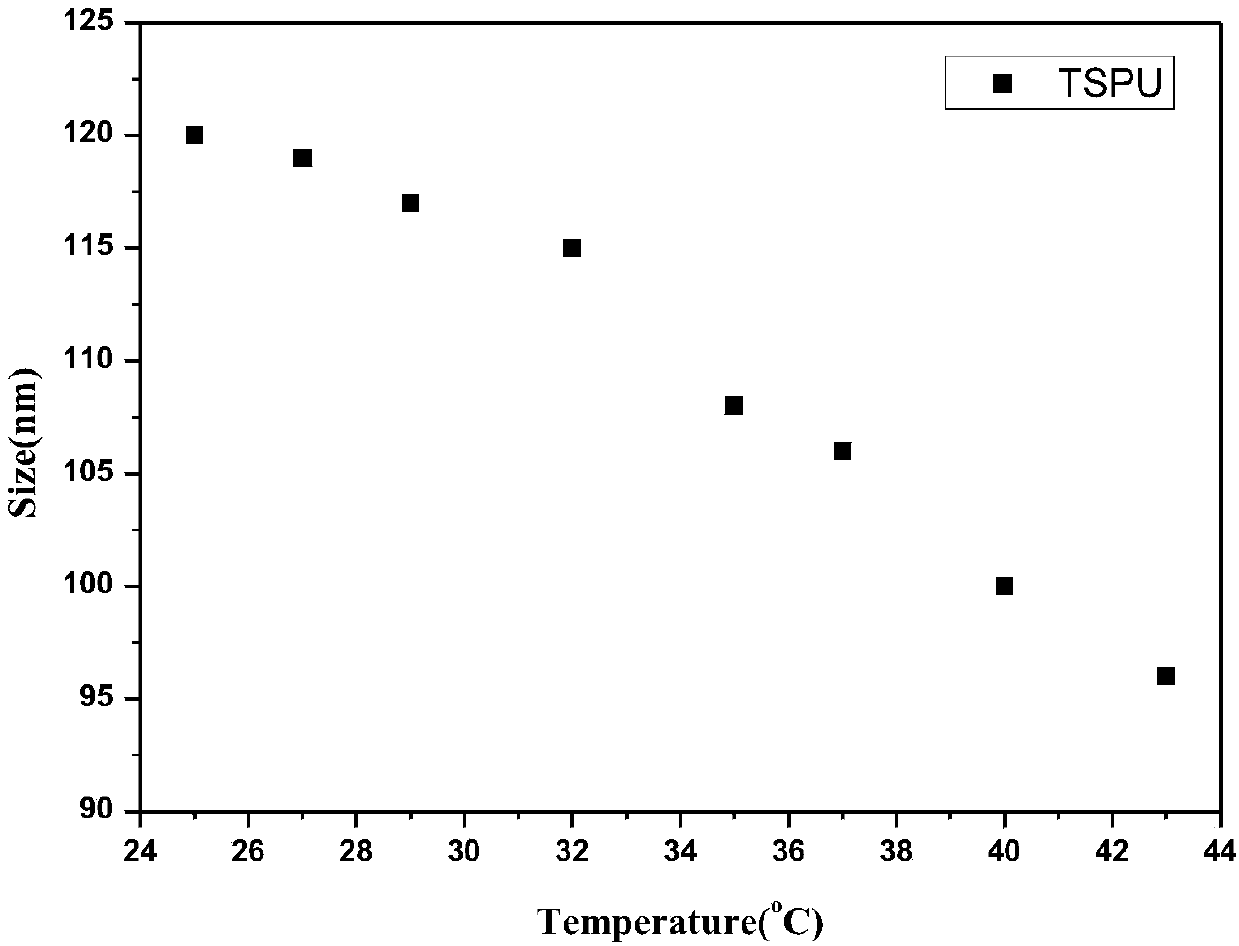

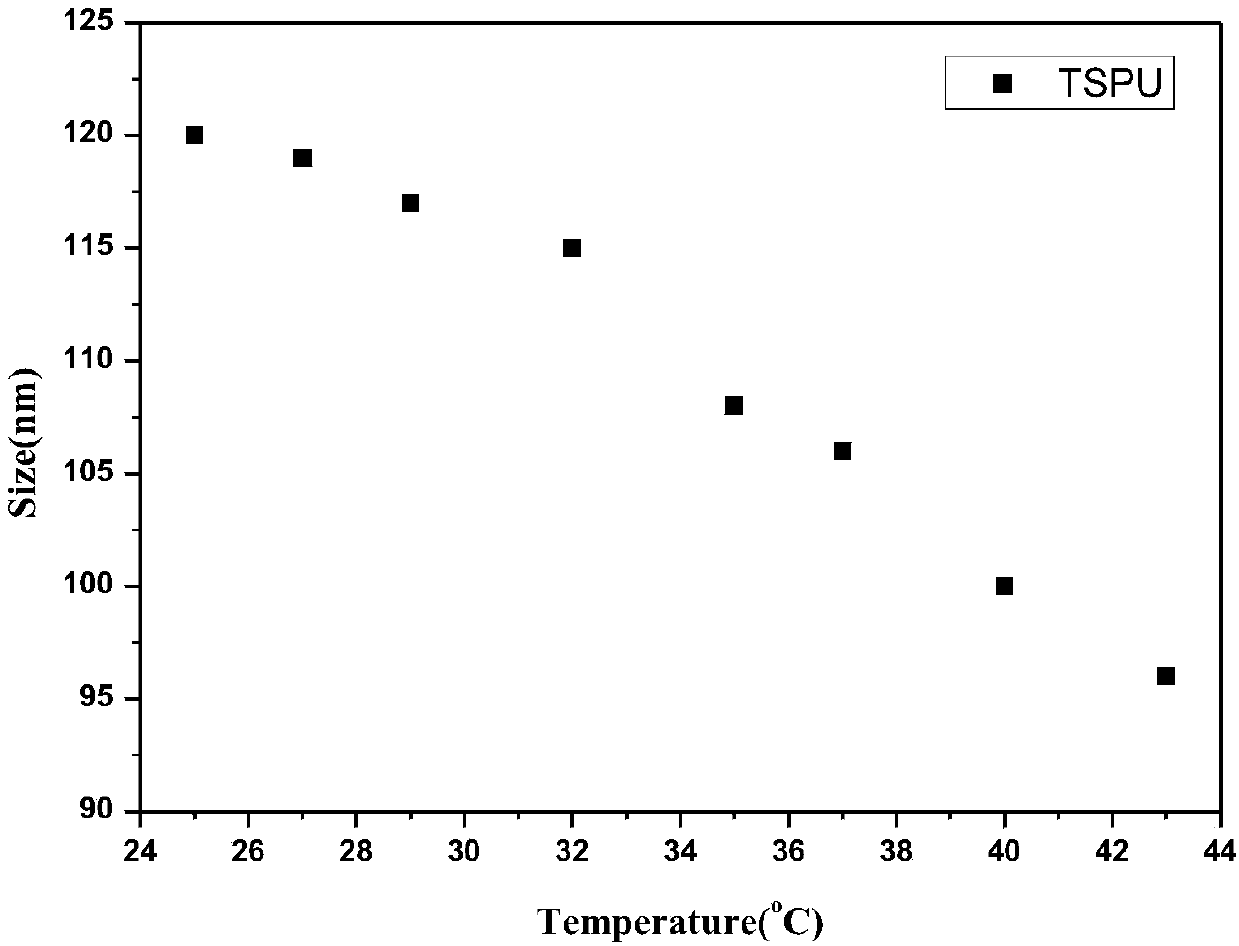

[0025] A kind of linear thermosensitive polyurethane, its preparation method is as follows:

[0026] S1. In a 100mL two-necked bottle, add 0.02mol (2.2632g) N-isopropylacrylamide, 0.02mol (1.2217g) ethanolamine, 2 1. Under the condition of 65°C and magnetic stirring for 36 hours, the monomer molecule M containing a hydroxyl group and having a temperature-sensitive effect can be obtained.

[0027] S2. Polycarbonate diol (PCDL-1000, indicating a molecular weight of 1000) was dewatered in a vacuum at -0.095MPa and 130°C for 2 hours, and set aside. Equipped with a condensing reflux device, a mechanical stirrer and a N 2 0.006mol (6g) PCDL-1000, 0.004mol (0.5365g) dimethylolpropionic acid (DMPA), 10mL N-methylpyrrolidone and 40mL acetone were added to a 250mL four-necked flask after dehydration treatment, and at 75°C Stir evenly under the conditions, then add 0.012mol (2.0183g) hexamethylene diisocyanate (HDI) and 0.0005mol (0.3g) catalyst dilaurate and butyltin, at this time NCO...

Embodiment 2

[0029] A kind of linear thermosensitive polyurethane, its preparation method is as follows:

[0030] S1. In a 100mL two-necked bottle, add 0.02mol (2.2632g) N-isopropylacrylamide, 0.02mol (1.2217g) ethanolamine, 2 1. Under the condition of 65°C and magnetic stirring for 36 hours, the monomer molecule M containing a hydroxyl group and having a temperature-sensitive effect can be obtained.

[0031] S2. Polycarbonate diol (PCDL-2000) was dehydrated under vacuum at -0.095MPa and 130°C for 2 hours, and set aside. Equipped with a condensing reflux device, a mechanical stirrer and a N 2 0.0056mol (11.2g) PCDL-2000, 0.004mol (0.5365g) dimethylolpropionic acid (DMPA), 10mL N-methylpyrrolidone and 30mL acetone were added to the 250mL four-necked bottle after dehydration treatment, and at 75 Stir evenly under the condition of ℃, then add 0.016mol (2.6911g) hexamethylene diisocyanate (HDI) and 0.0005mol (0.3g) catalyst dilaurate and butyltin, at this time NCO / OH=1.67:1. After reacting ...

Embodiment 3

[0033] A kind of linear thermosensitive polyurethane, its preparation method is as follows:

[0034] S1. In a 100mL two-necked bottle, add 0.02mol (2.2632g) N-isopropylacrylamide, 0.02mol (1.2217g) ethanolamine, 2 1. Under the condition of 65°C and magnetic stirring for 36 hours, the monomer molecule M containing a hydroxyl group and having a temperature-sensitive effect can be obtained.

[0035] S2. Polycarbonate diol (PCDL-500) was dewatered under vacuum at -0.095MPa and 130°C for 2 hours, and set aside. Equipped with a condensing reflux device, a mechanical stirrer and a N 2 0.0064mol (3.2g) PCDL-500, 0.004mol (0.5365g) dimethylolpropionic acid (DMPA), 10mL N-methylpyrrolidone and 40mL acetone were added to the 250mL four-necked bottle after dehydration treatment, at 75 Stir evenly under the condition of ℃, then add 0.012mol (2.0183g) hexamethylene diisocyanate (HDI) and 0.0005mol (0.3g) catalyst dilaurate and butyltin, at this time NCO / OH=1.15:1. After reacting for 3 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com