Graphite sealing material and preparation method thereof

A graphite sealing and graphite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as sealing failure, meson leakage, continuous or intermittent high temperature, meson pressure, meson corrosion, pre-tightening stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention also provides a kind of preparation method of graphite sealing material, comprises the following steps:

[0064] 1) After mixing fibers, rubber, rubber additives, non-asbestos fibers and fillers, a masterbatch is obtained;

[0065] 2) Rolling and vulcanizing the masterbatch obtained in the above steps to obtain a sealing material.

[0066] The selection and optimization principles of raw materials in the above preparation method in the present invention can correspond to the selection and optimization principles of raw materials in the aforementioned graphite sealing material, and will not be repeated here.

[0067] The present invention has no special restrictions on the pretreatment process of rubber in the preparation process, and the rubber pretreatment steps well known to those skilled in the art can be used. Those skilled in the art can select and adjust according to actual production conditions, product quality and use requirements. , the r...

Embodiment 1

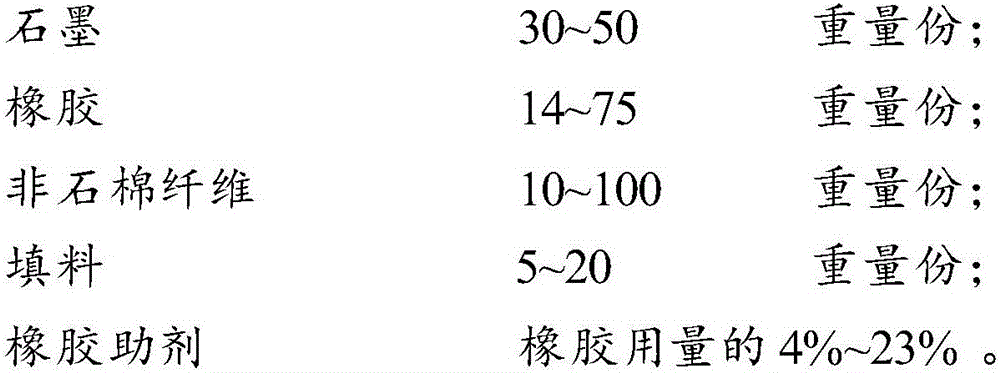

[0098] Refer to Table 1 for the production formula of graphite sealing liner plate type I.

[0099] Table 1

[0100] Thickness: 0.25~3.00mm Graphite sealing liner plate type I Raw material name Actual dosage (kg) Nitrile rubber 28.00 total 28.00 sulfur powder 0.96 Accelerator 0.90 Zinc oxide 1.80 plasticizer 0.50 Antiaging agent 0.80 total 4.96 Silica 10.00 Kaolin 13.00 graphite powder 45.00 Man-made mineral fiber 44.00 Aramid pulp 10 total 122.00 total 154.96 Toluene 85L Alcohol 22L

[0101] Preparation steps:

[0102] Process 1: Mastication of nitrile rubber

[0103] According to the dosage specified in the formula, weigh the nitrile rubber (tolerance ± 0.2kg);

[0104] The weighed nitrile rubber is masticated twice on a rubber mixing machine with a roller temperature of 42°C, thinned and then punched into a film for later use.

...

Embodiment 2

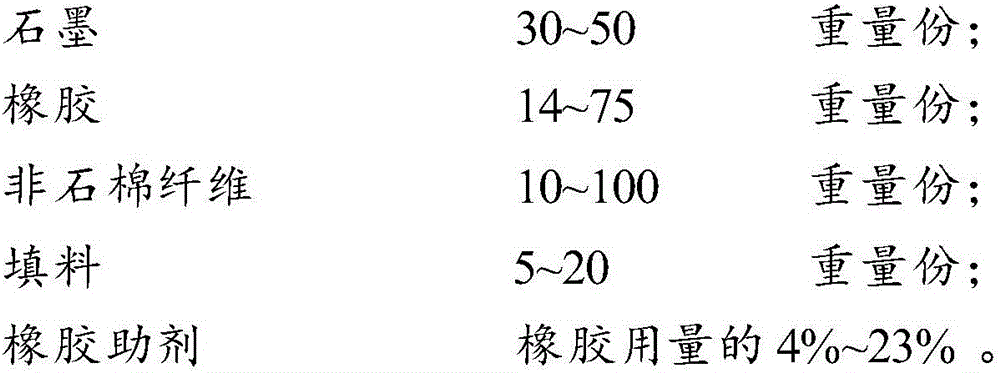

[0135] Refer to Table 3 for the production formula of graphite sealing backing plate Type II.

[0136] table 3

[0137] Thickness: 0.25~3.00mm Graphite sealing backing plate type II Raw material name Actual dosage (kg) Hydrogenated nitrile rubber 32.00 total 32.00 sulfur powder 1.11 Accelerator 0.94 Zinc oxide 1.50 plasticizer 0.90 Antiaging agent 0.60 total 5.05 Silica 12.00 carbon black 5.00 graphite powder 50.00 Man-made mineral fiber 36.00 Aramid pulp 15.00 total 118.00 total 155.05 Toluene 98L Alcohol 43L

[0138] Preparation steps:

[0139] Process 1: mastication of hydrogenated nitrile rubber

[0140] Weigh the hydrogenated nitrile rubber (tolerance ± 0.2kg) according to the dosage specified in the formula;

[0141] The weighed hydrogenated nitrile rubber is masticated twice on a rubber mixing machine with a roller temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com