Self-moisture-absorption cold-forming polyvinyl chloride composite material for packaging drugs and preparation method of self-moisture-absorption cold-forming polyvinyl chloride composite material

A polyvinyl chloride and composite material technology, applied in the field of pharmaceutical packaging, can solve the problems of small bubbles and can not put desiccant, etc., and achieve the effects of improving hygroscopicity, reasonable composition and strong reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

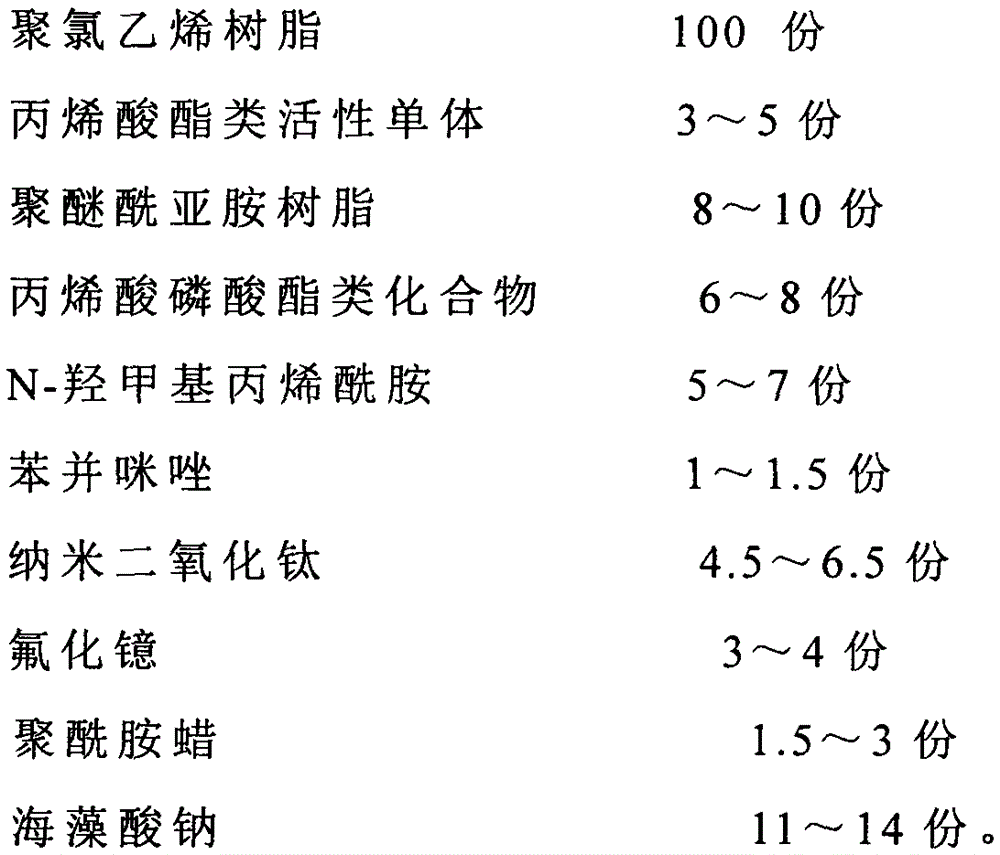

Method used

Image

Examples

Embodiment 1

[0030] Add 60g of phosphate methacrylate, 30g of 2-hydroxyethyl acrylate, and 50g of N-methylolacrylamide into the container, and react at 90°C for 2 hours; then add 10g of benzimidazole, 30g of polyamide wax, ℃ for 1 hour; then add 45g of nano-titanium dioxide and 140g of sodium alginate, and react at 140°C for 0.5 hours; naturally cool to obtain a modified product; the above modified product, 1000g of polyvinyl chloride resin, 80g of polyetherimide resin and adding 30g of ytterbium fluoride into a screw extruder for mixing and extruding to obtain polyvinyl chloride composite particles; the above polyvinyl chloride composite particles are calendered to obtain self-hygroscopic cold stamping polyvinyl chloride composite materials for pharmaceutical packaging.

[0031] When calendering, use a four-roller calender, the two-roller refining temperature is 165-170 ° C, the refining time is 12-15 minutes; the calendering temperature is 202-205 ° C, the calendering speed is 8.5-11 m / mi...

Embodiment 2

[0033] Add 80g of phosphate methacrylate, 30g of 2-hydroxyethyl acrylate, and 70g of N-methylolacrylamide into the container in sequence, and react at 90°C for 2 hours; then add 15g of benzimidazole and 15g of polyamide wax, ℃ for 1 hour; then add 45g of nano-titanium dioxide and 140g of sodium alginate, and react at 140°C for 0.5 hours; naturally cool to obtain a modified product; the above modified product, 1000g of polyvinyl chloride resin, 100g of polyetherimide resin and adding 30g of ytterbium fluoride into a screw extruder for mixing and extruding to obtain polyvinyl chloride composite particles; the above polyvinyl chloride composite particles are calendered to obtain self-hygroscopic cold stamping polyvinyl chloride composite materials for pharmaceutical packaging.

[0034] When calendering, use a four-roller calender, the two-roller refining temperature is 165-170 ° C, the refining time is 12-15 minutes; the calendering temperature is 202-205 ° C, the calendering spee...

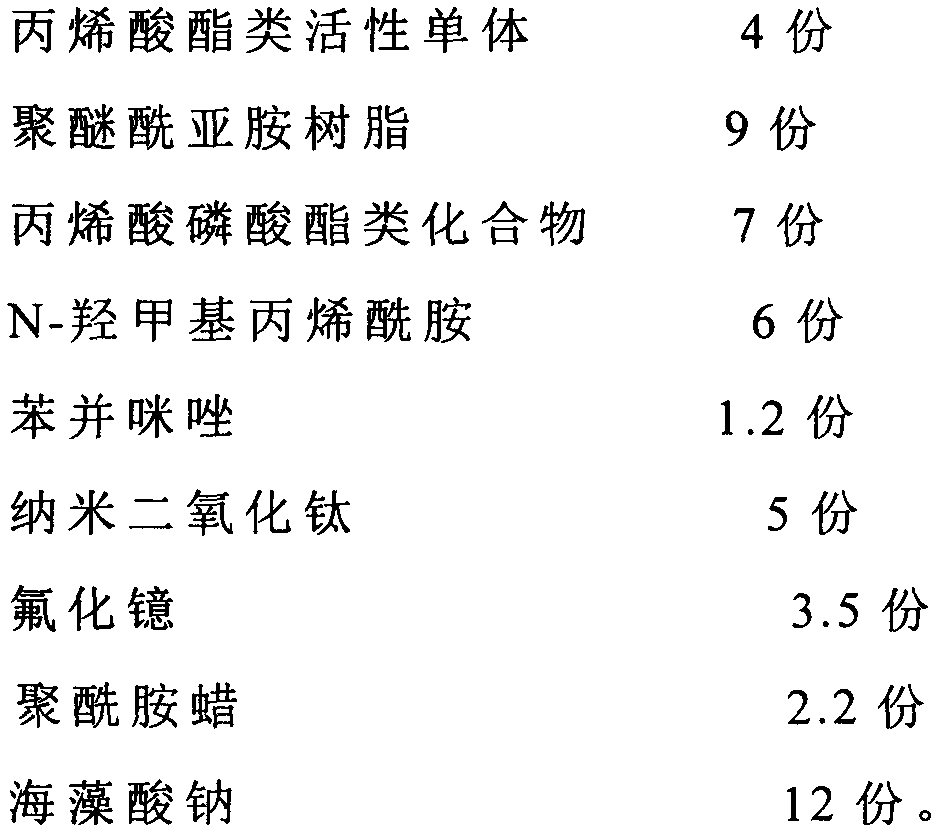

Embodiment 3

[0036] Add 70g of phosphate methacrylate, 40g of 2-hydroxyethyl acrylate, and 60g of N-methylolacrylamide into the container in turn, and react at 90°C for 2 hours; then add 12g of benzimidazole and 22g of polyamide wax, ℃ for 1 hour; then add 50g of nano-titanium dioxide and 120g of sodium alginate, and react at 140°C for 0.5 hours; naturally cool to obtain a modified product; the above modified product, 1000g of polyvinyl chloride resin, 90g of polyetherimide resin and adding 35g of ytterbium fluoride into a screw extruder for mixing and extruding to obtain polyvinyl chloride composite particles; the above polyvinyl chloride composite particles are calendered to obtain self-hygroscopic cold stamping polyvinyl chloride composite materials for pharmaceutical packaging.

[0037] When calendering, use a four-roller calender, the two-roller refining temperature is 165-170 ° C, the refining time is 12-15 minutes; the calendering temperature is 202-205 ° C, the calendering speed is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com