Organosilicone modified epoxy resin packaging material and LED packaging adhesive

A technology of epoxy resin and packaging material, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of low surface tension, performance degradation, surface pollution, etc., and achieve high light transmittance and high refractive index , The effect of good high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

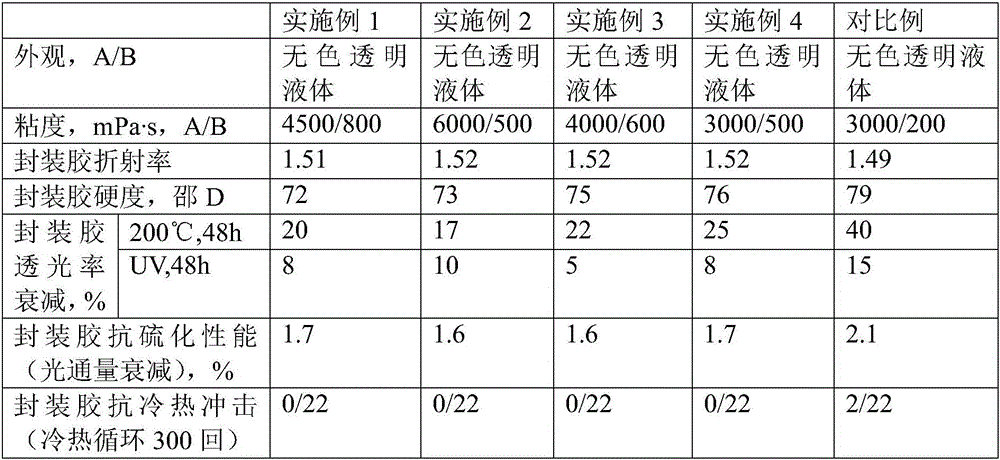

Examples

preparation example 1

[0070] Preparation Example 1: Preparation of Epoxy- and Vinyl-Containing Organosilicon Compounds—Epoxy Propoxy Propyl-Vinyl-Phenyl Silicone Resin

[0071] In a 2L four-necked flask with a stirring bar, a thermometer, and a condenser tube, drop 266.4g of KH560, 292.8g of diphenyldimethoxysiloxane, 216g of dimethyldimethoxysiloxane, 162g of Hexamethyldisiloxane and 37.2g of divinyltetramethyldisiloxane were stirred evenly, then 0.8336g of tetramethylammonium hydroxide and 216g of deionized water were added, and reacted in an ice-water bath for 2 hours. Then the temperature was raised to 90°C for 5h. After standing for stratification, the lower liquid was washed with water until neutral. Then, under vacuum, the temperature was raised to 100° C. to remove low molecules for 3 hours, and the target silicone resin product in the form of a colorless and transparent liquid was obtained. The measured viscosity of the product is 8000 mPa·s, the refractive index is 1.53, the vinyl conte...

preparation example 2

[0072] Preparation Example 2: Preparation of Epoxy- and Vinyl-Containing Organosilicon Compounds—Epoxycyclohexylethyl-Vinyl-Phenyl Silicone Resin

[0073] In a 2L four-necked flask with a stirring bar, a thermometer, and a condenser tube, drop 240.8g of 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane, 93g of phenyltrimethoxysilane Oxane, 162g hexamethyldisiloxane, 37.2g divinyltetramethyldisiloxane, stir evenly, add 0.8336g tetramethylammonium hydroxide and 216g deionized water, react in ice water bath for 2h . Then the temperature was raised to 90°C for 5h. After standing for stratification, the lower liquid was washed with water until neutral. Then, under vacuum, the temperature was raised to 100° C. to remove low molecules for 3 hours, and the target silicone resin product in the form of a colorless and transparent liquid was obtained. The measured viscosity of the product is 11000 mPa·s, the refractive index is 1.53, the vinyl content is 1.1%, and the epoxy group content is...

preparation example 3

[0074] Preparation Example 3: Preparation of Epoxy- and Vinyl-Containing Organosilicon Compounds—Epoxycyclohexylethyl-Vinyl-Phenyl Silicone Oil

[0075] Add 200g of octaphenylcyclotetrasiloxane, 50g of octamethylcyclotetrasiloxane, 20g of tetraepoxycyclohexylethyl-tetramethylsiloxane in the four-necked reaction flask equipped with stirring, thermometer and condenser Cyclotetrasiloxane (silane coupling agent X-40-2670, Japan Shin-Etsu Co.), 2.4g vinyl capping agent, then add 0.1g of potassium silanolate catalyst and 1g of dimethyl sulfoxide, heat up after closed reaction Stir, react at 150°C for 6 hours, cool down to 40°C and use excess propionic acid to neutralize, pressurize and filter to remove impurities, heat the filtrate to 200°C to remove low molecules in a vacuum to obtain a colorless, transparent, slightly odorous epoxy group Cyclohexylethyl-vinyl-phenyl silicone oil product. The measured viscosity of the product is 6000 mPa·s, the refractive index is 1.53, the mass c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com