Preparation method for phycocyanin polypeptide

A technology of phycocyanin and papain, which is applied in the field of protein enzymatic hydrolysis, can solve the problems of singleness and low efficiency of proteolysis, and achieve the effect of improving enzymatic hydrolysis efficiency and solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

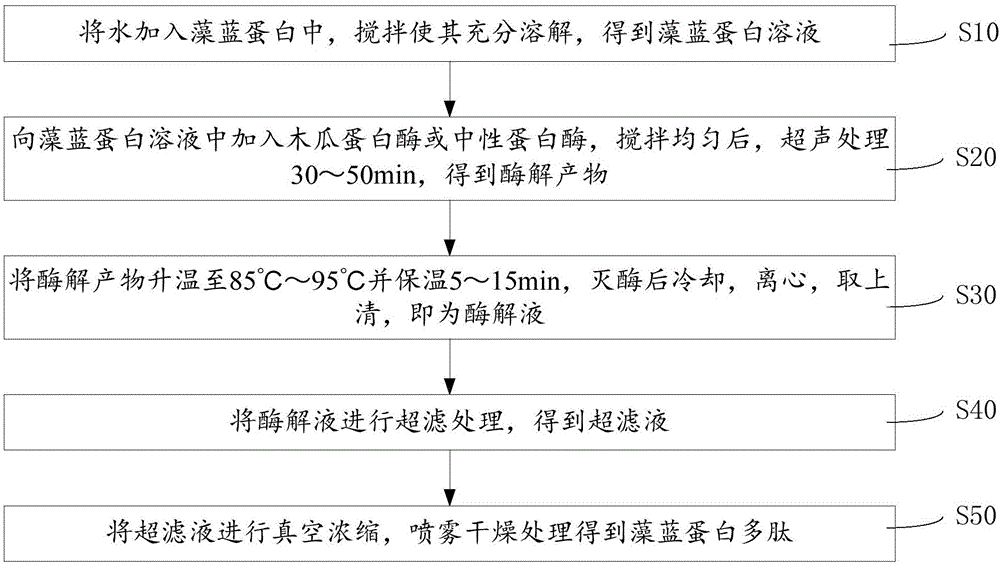

[0023] Please refer to figure 1 , the preparation method of the phycocyanin polypeptide of one embodiment, comprises the following steps:

[0024] S10, adding water into the phycocyanin, stirring to fully dissolve it, and obtaining a phycocyanin solution.

[0025] Among them, the purity of phycocyanin A 620 / A 280 >2. The solid-liquid ratio of phycocyanin and water can be 1:10-1:50.

[0026] In the operation of S10, the phycocyanin is dissolved by magnetic stirring at a constant temperature, and the temperature may be 50° C. to 55° C. The stirring time may be 20-40 minutes.

[0027] S20. Add papain or neutral protease to the phycocyanin solution, stir evenly, and ultrasonically treat for 30-50 minutes to obtain an enzymatic hydrolysis product.

[0028] Wherein, the ultrasonic treatment can be carried out in a water bath ultrasonic device.

[0029] Wherein, the enzyme activity of papain can be 5×10 5 ~10×10 5 U / g. The mass ratio of papain and phycocyanin may be 1:100-...

Embodiment 1

[0041] (1) Weigh 5g phycocyanin (A 620 / A 280 >2) Put it into a container, add 200mL of distilled water, and stir on a constant temperature magnetic stirrer for 30 minutes to fully dissolve it to obtain a phycocyanin solution;

[0042] (2) The phycocyanin solution obtained in step (1) is adjusted to pH 6.0, and then 1.5g of papain (enzyme activity 8×10 5 U / g), after stirring evenly, ultrasonically treat in a water bath ultrasonic device, the ultrasonic power is 600W, the reaction temperature is 55°C, and the reaction time is 50min, to obtain the enzymatic hydrolysis product;

[0043] (3) Rapidly raise the temperature of the enzymolysis reaction product to 90°C for 10 minutes, cool to 30°C after inactivating the enzyme, centrifuge at 10,000 r / min for 10 minutes, take the supernatant, which is the enzymolysis solution, and the degree of hydrolysis of phycocyanin is 13.68 %;

[0044] (4) The enzymolysis solution obtained in step (3) is subjected to ultrafiltration treatment by...

Embodiment 2

[0047] (1) Weigh 5g phycocyanin (A 620 / A 280>2) Put it into a container, add 50mL of distilled water, and stir on a constant temperature magnetic stirrer until fully dissolved to obtain a phycocyanin solution;

[0048] (2) the pH of the phycocyanin solution obtained in step (1) is adjusted to 5.0, then add papain by 5% of the phycocyanin weight (enzyme activity 10 × 10 5 U / g), after stirring evenly, ultrasonic treatment in a water bath ultrasonic device, the ultrasonic power is 300W, the reaction temperature is 50°C, and the reaction time is 30min, to obtain the enzymatic hydrolysis product;

[0049] (3) Rapidly raise the temperature of the enzymolysis reaction product to 85°C and keep it warm for 15 minutes, cool it down to 30°C after inactivating the enzyme, centrifuge at 10,000r / min for 10 minutes, take the supernatant, which is the enzymolysis solution, and the hydrolysis degree of phycocyanin is measured as 12.97 %;

[0050] (4) using a molecular weight cut-off of 10k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com