A kind of particle reinforced lightweight microlattice composite material and preparation method thereof

A composite material and micro-lattice technology, which is applied in the direction of additive processing, metal material coating technology, liquid chemical plating, etc., can solve the problems of difficult control of molding pressure, many manual operations, complicated process flow, etc. Strong design, good film adhesion and fast deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

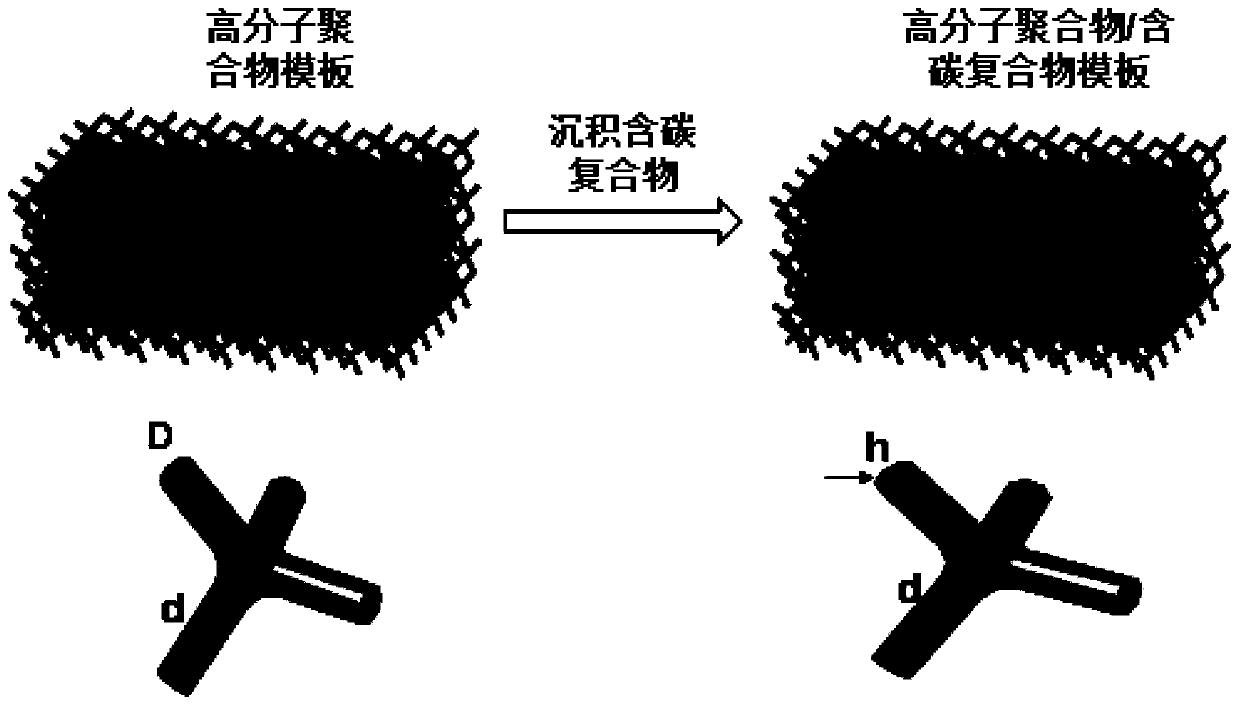

[0058] Such as figure 1 As shown, the preparation method of the particle-reinforced lightweight microlattice composite material according to the present invention includes the following steps:

[0059] 1) Using different rapid prototyping technologies to prepare templates of different materials, different lattice structures and parameters,

[0060] among them:

[0061] a) The rapid prototyping technology includes (at least) one selected from the following processes: light curing three-dimensional molding technology (SLA), digital light processing (DLP), selective laser sintering (SLS), fusion molding (FDM) );

[0062] In an embodiment of the present invention, the process parameters of SLA are: filling scanning speed: 200-500mm / s, scanning pitch: 0.1-0.5mm, spot compensation diameter: 0.1-0.3mm, supporting scanning Speed: 80~120mm / s, jumping speed: 300~800mm / s, waiting time between layers: 1~5s, table feed speed: 2~10mm / s, table immersion depth: 5~10mm;

[0063] In an embodiment of th...

Embodiment 1

[0085] 1) Preparation of three-dimensional microlattice polymer template

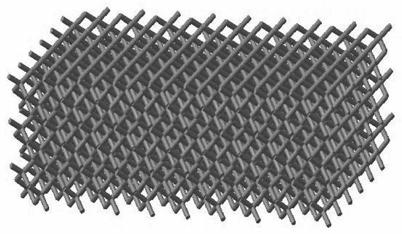

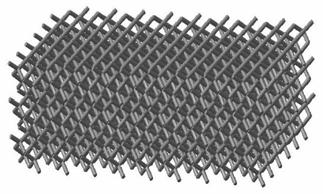

[0086] Using Digital Light Processing (DLP) to prepare diamonds

[0087] Template of regular tetrahedron structure, such as figure 2 Shown.

[0088] The process parameters of digital light processing (DLP) are: projection resolution 768×480, projection light band 405nm, slice thickness 30μm, curing at room temperature, curing time per layer 6s, and each movement time of the stepper motor is 2s.

[0089] The template material used in digital light processing (DLP) is: composite photosensitive resin DXZ-100, the main component of which is methacrylic resin.

[0090] The size of the diamond lattice structure template is: the length is 28.03mm, the width is 18.94mm, and the height is 9.54mm. The diameter of each column is 0.3mm, and the length of the column is 1mm. This structure has high structural stability, elasticity and physical stability against destruction.

[0091] 2) Depositing a Ni-P-diamond film on the s...

Embodiment 2

[0103] 1) Preparation of three-dimensional microlattice polymer template

[0104] The template of diamond regular tetrahedron structure is prepared by light-curing three-dimensional molding technology (Stereo Lithography Appearance, SL or SLA).

[0105] In this embodiment, the process parameters of SLA are: filling scanning speed is 300mm / s, scanning distance is 0.1mm, spot compensation diameter is 0.2mm, supporting scanning speed is 100mm / s, and jumping speed It is 600mm / s, the waiting time between layers is 5s, the table feed speed is 5mm / s, and the table immersion depth is 6mm.

[0106] The template material used in light-curing molding technology (SLA) is: composite photosensitive resin EX-200, whose main component is acrylic resin.

[0107] The size of the diamond lattice structure template is: the length is 28.94mm, the width is 19.68mm, and the height is 10.05mm. The diameter of each column is 0.6mm, and the length of the column is 2mm.

[0108] 2) Depositing a Ni-P-boron nitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com