A kind of multi-layer through-hole high permeability polymer microfiltration membrane and preparation method thereof

A multi-layer through-hole and polymer technology, applied in the field of membrane materials, can solve the problems of low microfiltration membrane strength, poor permeability, irregular distribution of multi-layer microfiltration membrane through-holes, etc., and achieve strong order , film-making time is short, the effect of improving pollution resistance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

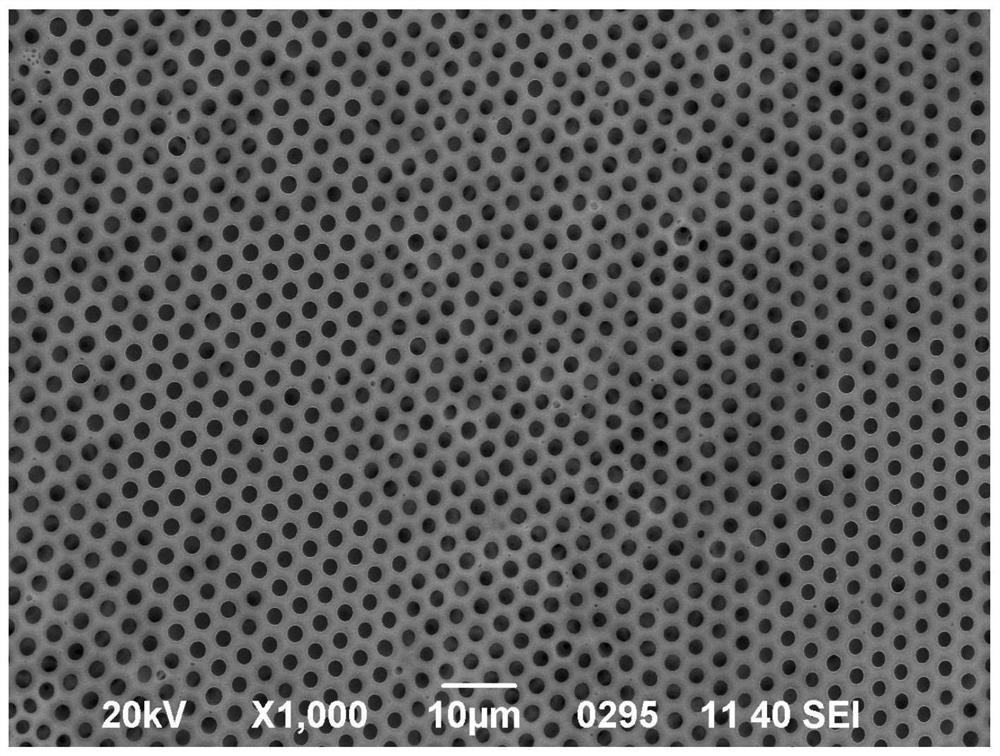

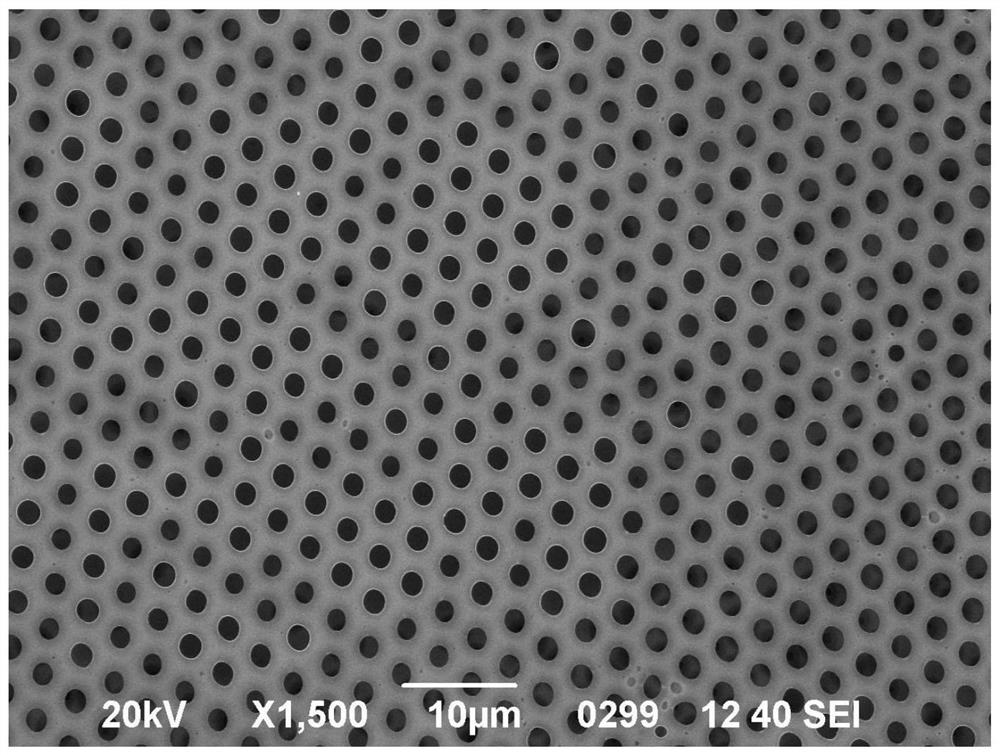

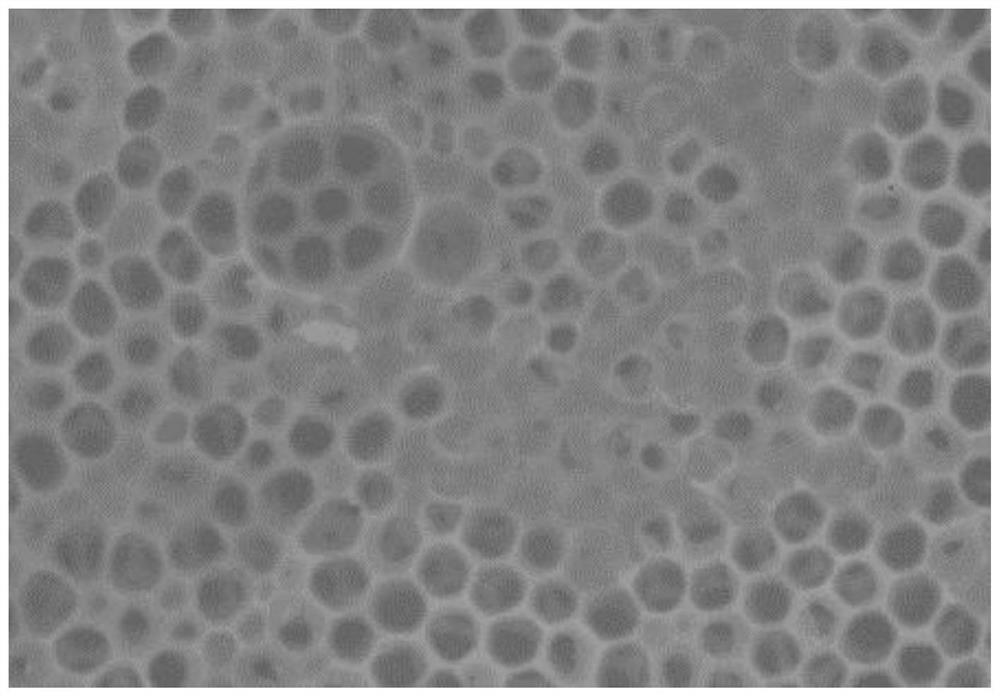

[0036] A two-layer through-hole high-permeability brominated polyphenylene ether microfiltration membrane, comprising a brominated polyphenylene ether microfiltration membrane body, a multi-layer pore structure in the brominated polyphenylene ether microfiltration membrane body, and the pores distributed on the pore walls Silica microspheres with a multi-layer porous structure have a single layer thickness of 4 μm, a pore diameter of 2 μm, and a particle size of the silica microspheres of 30 nm.

[0037] The preparation method of brominated polyphenylene ether microfiltration membrane is:

[0038] 1) Preparation and modification of silica microspheres: Dissolve 40g of ethanol, 3.85ml of 13mol / L ammonia water, and 0.5g of potassium chloride into 0.12g of water, mix evenly, then transfer to a three-necked flask, stir at a constant temperature of 20°C, and Add 40ml of ethanol and 2.1g of TEOS into the beaker, mix them evenly, drop them into the three-neck flask drop by drop with ...

Embodiment 2

[0042] A 3-layer through-hole high-permeability cellulose acetate microfiltration membrane, including a cellulose acetate microfiltration membrane body, a multilayer pore structure in the body, and silica microspheres distributed on the pore wall, the multilayer pore structure is single The layer thickness is 6 μm, the pore size is 1.8 μm, and the particle size of silica microspheres is 40 nm.

[0043] The preparation method of cellulose acetate microfiltration membrane is:

[0044] 1) Preparation and modification of silica microspheres: Dissolve 40g of ethanol, 3.85ml of 13mol / L ammonia water, and 0.5g of potassium chloride into 0.15g of water, mix well and then transfer to a three-necked flask, stir at a constant temperature of 20°C, Add 40ml of ethanol and 2.1g of TEOS into the beaker, mix them evenly, drop them into the three-neck flask drop by drop with a dropper, filter after reacting for 3 hours, centrifuge the filtered solid and wash it with ethanol to obtain a silica ...

Embodiment 3

[0048] A 4-layer through-hole high-permeability polyethylene glycol-modified polystyrene microfiltration membrane, including a polyethylene glycol-modified polystyrene microfiltration membrane body, a multi-layer pore structure in the body, and the pores distributed on the pore wall Silica microspheres with a multi-layer porous structure have a single layer thickness of 8 μm, a pore diameter of 1.6 μm, and a particle size of the silica microspheres of 50 nm.

[0049] The preparation method of polyethylene glycol modified polystyrene microfiltration membrane is:

[0050] 1) Preparation and modification of silica microspheres: 1) Preparation and modification of silica microspheres: dissolve 40g of ethanol, 3.85ml of 13mol / L ammonia water, and 0.5g of potassium chloride into 0.2g of water, mix After uniformity, move it into a three-necked flask, stir at a constant temperature of 20°C, add 40ml of ethanol and 2.1g TEOS to the beaker, mix evenly, drop it into the three-necked flask...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com