asphalt pavement structure

A technology for asphalt pavement and asphalt surface layer, applied in the field of traffic engineering, can solve the problems of unsatisfactory comprehensive performance of asphalt mixture of thermal insulation layer, limited effect of pavement temperature control, easy wear and loss of thermal insulation coating, etc. The effect of ventilation and heat dissipation, preventing the downward conduction of heat, and enhancing the resistance to water damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The asphalt pavement structure in this embodiment is suitable for areas where the annual average temperature is below 10°C.

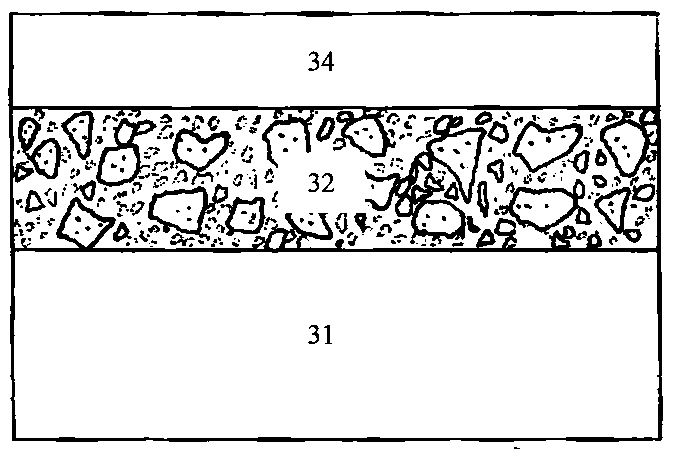

[0039] Such as Figures 9 to 11 As shown, a kind of asphalt pavement structure of the present embodiment comprises an asphalt pavement 3, and the asphalt pavement 3 includes a lower layer 31, a middle surface layer 32, a drainage heat insulation layer 33 and an upper layer 34 arranged sequentially from bottom to top, The drainage heat insulation layer 33 is an asphalt mixture layer with a porosity of 8% to 20%. The asphalt pavement structure of this embodiment has both drainage and temperature control functions, and a drainage and heat insulation layer 33 is set between the upper layer 34 and the middle layer 32 of the asphalt surface layer 3, compared with setting a drainage asphalt concrete PAC or PAC on the road surface. The open-graded asphalt wear layer OGFC not only drains the asphalt surface layer 3 that is most affected by external water...

Embodiment 2

[0055] The asphalt pavement structure of this embodiment is suitable for areas with an annual average temperature of 10°C to 15°C.

[0056] In this embodiment, the structure of the asphalt pavement is roughly the same as that of Embodiment 1, except that the middle surface layer 32 also serves as the drainage and heat insulation layer 33, and the drainage and heat insulation layer 33 is fine-grained asphalt with a porosity of 15% to 20%. The mixture layer (this example is the open-graded asphalt wear course OGFC-13), the middle surface layer 32 is a medium-grained asphalt mixture layer with a void ratio of 8% to 15% (this example is the open-graded asphalt wear course OGFC-16), the thickness of the middle surface layer 32 is T3, wherein, 50mm≤T3≤70mm.

[0057] After selecting the specific values of T1, T2, T3, and T4 within the above range, determine the thickness of the remaining layers of the asphalt pavement structure according to the method of my country's highway asphal...

Embodiment 3

[0060] The asphalt pavement structure in this embodiment is suitable for areas where the average temperature is above 15° C. and where the cooling effect of natural ventilation and drainage is limited.

[0061] The structure of the asphalt pavement in this embodiment is substantially the same as that in Embodiment 2, except that: the drainage heat insulation layer 33 contains water-retaining materials, and the water-retention materials are poured into the drainage heat insulation layer 33 after paving.

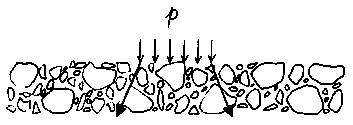

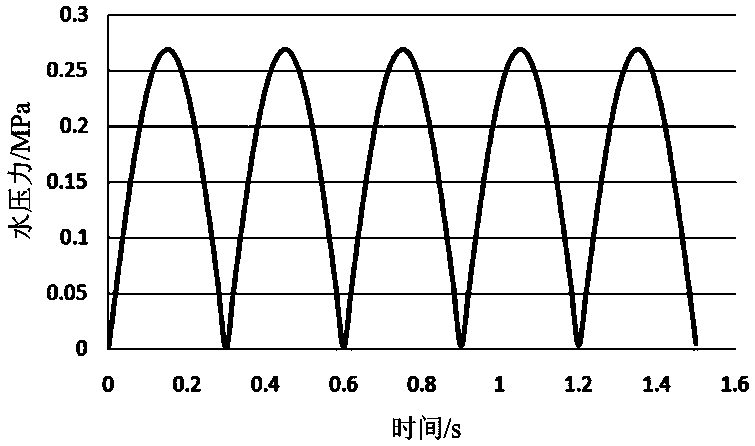

[0062] The drainage heat insulation layer 33 implements partial water retention to improve the cooling effect, so that part of the pores of the drainage heat insulation layer 33 are filled with water retention materials, and its temperature control ability is stronger, so as to prevent the formation of pore water pressure in the drainage heat insulation layer 33 under the action of the wheel load , can further actively control moisture, help to reduce the pore water pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com