A high-brightness and high-stiffness reflective film and its preparation method

A high-stiffness, reflective film technology, applied in the direction of instruments, optics, optical components, etc., can solve the problems of scratching the light guide plate and low stiffness of the reflective film, achieve uniform luminance of reflected light, improve luminance and its uniformity , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] A preparation method of a high-brightness and high-stiffness reflective film provided by the present invention comprises the following steps:

[0063] (1) Prepare inorganic particle resin masterbatch, mix and granulate inorganic particles and carrier resin materials to obtain inorganic particle resin masterbatch; use three-layer co-extrusion for casting, longitudinal stretching, transverse stretching, heat setting, cooling , traction, winding and slitting to obtain the reflective thin layer.

[0064] (2) Coat one side of the reflective layer with a hardened layer online, and dry in an oven at 100°C-120°C for 1min-2min.

[0065] (3) Wet coating method is used to coat the prepared coating solution containing scattering particles on the other side of the reflective layer, and use a high-pressure mercury lamp to 2 Radiation curing.

[0066] The reflective film prepared by the present invention is tested according to the following method:

[0067] Reflectance: According t...

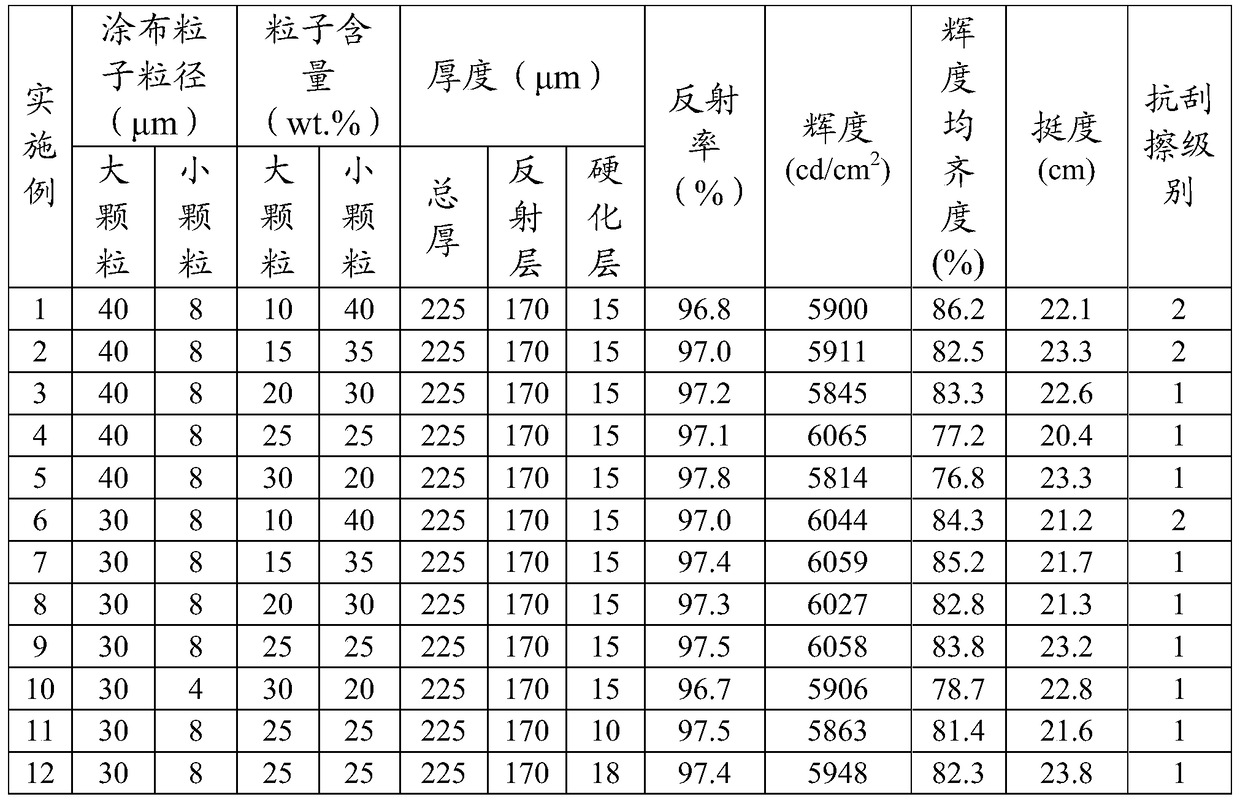

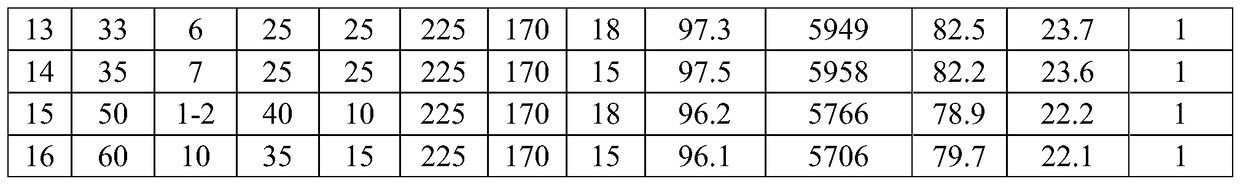

Embodiment 1

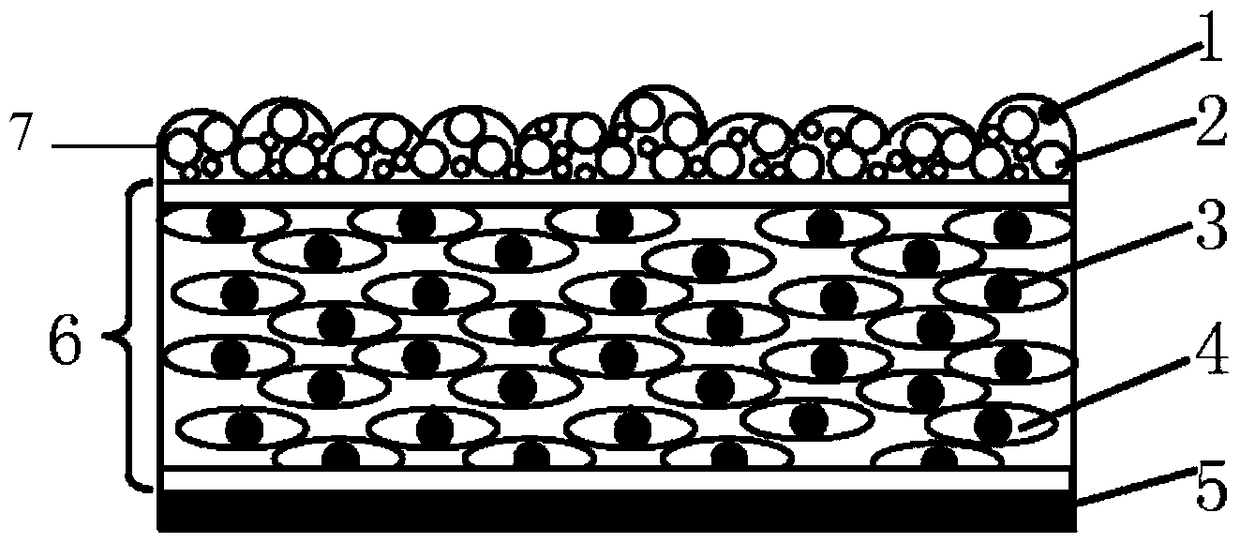

[0072] The high-brightness and high-stiffness reflective film provided by the present invention is composed of a reflective layer, a hardened layer, and a coated particle layer; the upper surface of the reflective layer is coated with a coated particle layer , the lower surface of the reflective layer is coated with a hardened layer; the coating particle layer includes adhesive resin and diffusion particles, and the diffusion particles are bonded to the surface of the reflective layer through the adhesive resin; the diffusion particles include large Particles and small particles. Wherein, the thickness of the hardened layer is 15 μm, the thickness of the reflective layer is 170 μm, and the total thickness of the reflective film is 225 μm.

[0073] The polyester resin in the reflective layer is PET with a content of 70%, the incompatible carrier resin is polyolefin with a content of 15%, and the inorganic particles are rutile titanium dioxide with a content of 15%;

[0074] Th...

Embodiment 2

[0081] High-brightness high-stiffness reflective film as provided in Example 1, wherein,

[0082] The thickness of the hardened layer is 15 μm, the thickness of the reflection layer is 170 μm, and the total thickness of the reflection film is 225 μm.

[0083] The polyester resin in the reflective layer is PET with a content of 70%, the incompatible carrier resin is polyolefin with a content of 15%, and the inorganic particles are rutile titanium dioxide with a content of 15%;

[0084] The reflective layer is an ABA three-layer co-extruded structure, wherein the thickness of the A layer accounts for 10% of the total thickness of the reflective layer, and the thickness of the B layer accounts for 90% of the total thickness of the reflective layer.

[0085] The hardened layer comprises a UV-curable resin glue and a UV curing agent, the UV-curable resin glue is selected from acrylic resin with a content of 75%, and the UV curing agent is selected from an epoxy resin curing agent w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com