Method for manufacturing laminated type soft battery cell for in-situ XRD (X-Ray Diffraction) testing

A manufacturing method and a laminated technology, which are applied in electrode manufacturing, electrolyte storage battery manufacturing, circuits, etc., can solve the problems of large influence of XRD diffraction background, complex overall structure, complex manufacturing, etc., and achieve simple and easy opening and preparation method Simple operation and little background effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

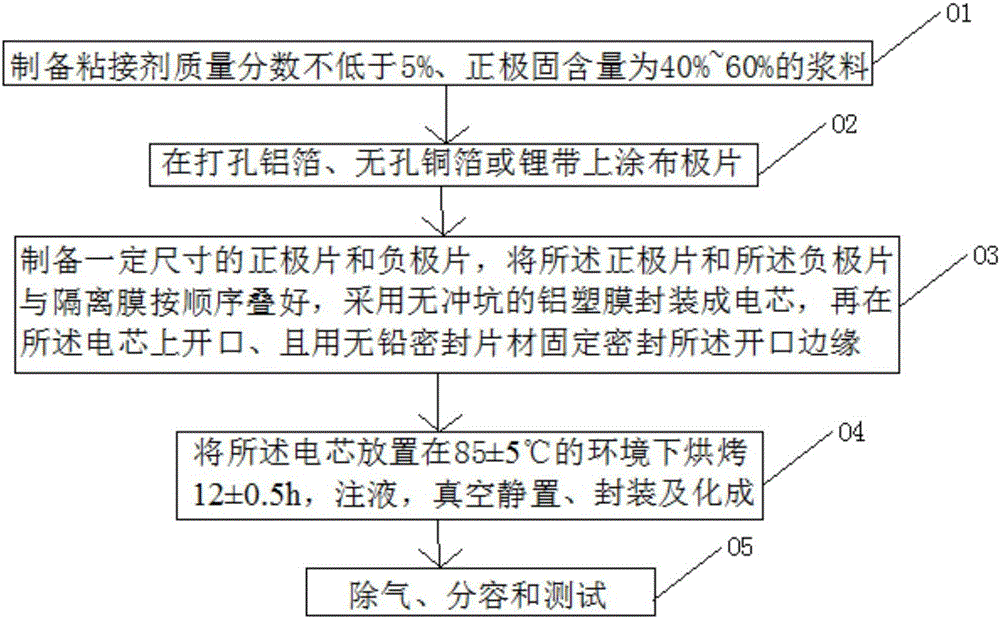

[0025] Please refer to figure 1 and figure 2 , a manufacturing method of a laminated soft-packed battery cell for in-situ XRD testing of the present invention, comprising the following steps:

[0026] 01. Prepare a slurry with a mass fraction of the binder of not less than 5% and a positive electrode solid content of 40% to 60%. Specifically, the active material, conductive carbon SP, binder, and powder are added and mixed evenly, and then an appropriate amount of NMP is added to stir, wherein the active material may be lithium iron phosphate powder. More specifically, in terms of mass fraction, the lithium iron phosphate powder accounts for 80%, the conductive carbon SP accounts for 10%, and the binder accounts for 10%. The solid content of the NMP is controlled at 50%, and the viscosity is 8000 mPa.s. It should be noted that the stirring time can be set to 1-2 hours, and the adhesive is PVDF or PTFE.

[0027] 02. Coat the pole piece on perforated aluminum foil, non-poro...

Embodiment 2

[0033] The only difference between Example 2 and Example 1 is that: the lithium iron phosphate powder in step 01 accounts for 85%, the conductive carbon SP accounts for 10%, and the adhesive PTFE accounts for 5%. For other processes, please refer to Example 1. description, which will not be repeated here.

Embodiment 3

[0035]The only difference between Example 3 and Example 1 is that the lithium iron phosphate powder in step 01 accounts for 70%, the conductive carbon SP accounts for 10%, and the adhesive PVDF accounts for 20%. Referring to the description of Embodiment 1, details are not repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com