Yttrium oxide-ferric oxide composite nano antibacterial material

A technology of ferric oxide and antibacterial materials, applied in the fields of chemicals for biological control, animal repellants, botanical equipment and methods, etc., to achieve enhanced antibacterial performance, excellent antibacterial performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

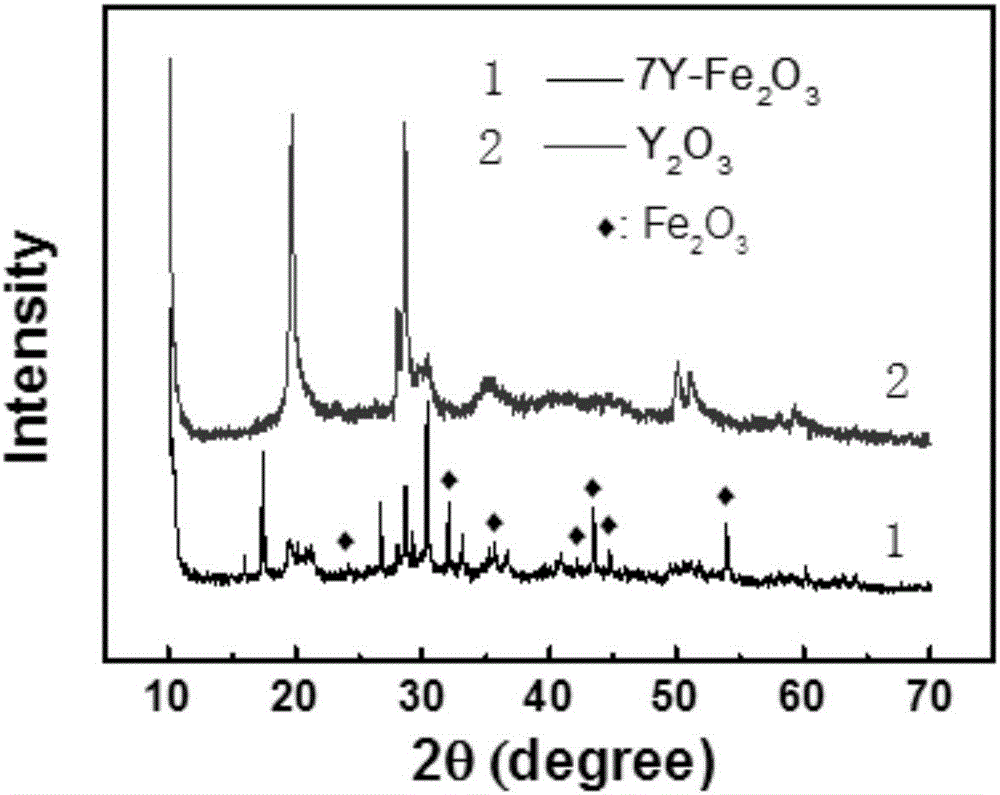

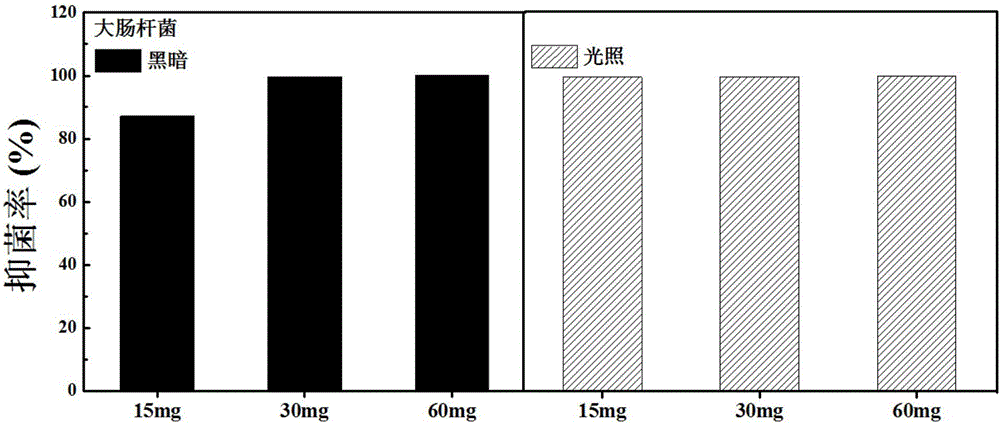

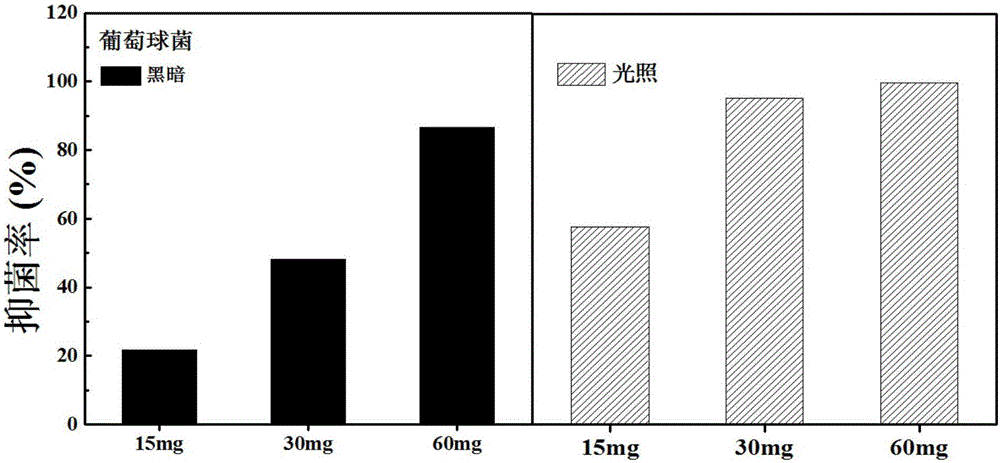

Image

Examples

Embodiment 1

[0038] The preparation and application of a yttrium oxide-ferric oxide composite nano antibacterial material of the present invention includes the following steps in sequence:

[0039] ⑴Add 8mmol FeSO 4 ·7H 2 O was dissolved in 15 mL of deionized water to prepare solution I;

[0040] ⑵ Put 1.6mmol of NaClO 3 Dissolve in 16mL of deionized water to prepare solution II;

[0041] (3) Add solution II to solution I drop by drop, stir while adding, to prepare solution III;

[0042] ⑷ Transfer solution III to the autoclave and react at 180°C for 12 hours;

[0043] ⑸After the solution is cooled, collect the precipitate and wash it with deionized water and absolute ethanol three times, and then dry it in an oven at 60°C for 10 hours to obtain nano-Fe 2 O 3 ;

[0044] ⑹ Weigh 1.552gY(NO 3 ) 3 ·6H 2 O, 0.5 g PVP and weighing 45 mg of the product of step ⑸ into the system containing 14 mL of water and 66 mL of ethanol and stirring uniformly, then transfer the solution to the autoclave, and react at 1...

Embodiment 2

[0055] The preparation and application of a yttrium oxide-ferric oxide composite nano antibacterial material of the present invention includes the following steps in sequence:

[0056] ⑴Add 8mmol FeSO 4 ·7H 2 O was dissolved in 15 mL of deionized water to prepare solution I;

[0057] ⑵The 1.6mmol NaClO 3 Dissolve in 16mL of deionized water to prepare solution II;

[0058] ⑶ Add solution II to solution I drop by drop, stir while adding, to prepare solution III;

[0059] ⑷ Transfer solution III to the autoclave and react at 180°C for 12 hours;

[0060] ⑸After the solution is cooled, collect the precipitate and wash it with deionized water and absolute ethanol three times, and then dry it in an oven at 60°C for 10 hours to obtain nano-Fe 2 O 3 ;

[0061] ⑹ Weigh 1.552gY(NO 3 ) 3 ·6H 2 O, 0.5 g PVP and weighing 45 mg of the product of step ⑸ into the system containing 14 mL of water and 66 mL of ethanol and stirring uniformly, then transfer the solution to the autoclave, and react at 180°C f...

Embodiment 3

[0072] The preparation and application of a yttrium oxide-ferric oxide composite nano antibacterial material of the present invention includes the following steps in sequence:

[0073] ⑴Add 8mmol FeSO 4 ·7H 2 O was dissolved in 15 mL of deionized water to prepare solution I;

[0074] ⑵ Put 1.6mmol of NaClO 3 Dissolve in 16mL of deionized water to prepare solution II;

[0075] ⑶ Add solution II to solution I drop by drop, stir while adding, to prepare solution III;

[0076] ⑷ Transfer solution III to the autoclave and react at 180°C for 12 hours;

[0077] ⑸After the solution is cooled, collect the precipitate and wash it with deionized water and absolute ethanol three times, and then dry it in an oven at 60°C for 10 hours to obtain nano-Fe 2 O 3 ;

[0078] ⑹ Weigh 1.552gY(NO 3 ) 3 ·6H 2 O, 0.5 g PVP and weighing 45 mg of the product of step ⑸ into the system containing 14 mL of water and 66 mL of ethanol and stirring uniformly, then transfer the solution to the autoclave, and react at 180...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com