A kind of sour cream product and preparation method thereof

A cream and product technology, applied in the direction of cream preparation, dairy products, applications, etc., can solve the problems of mascarpone cheese formula and process research, so as to improve the yield and the properties of sour cream products, The effect of silky texture and convenient consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

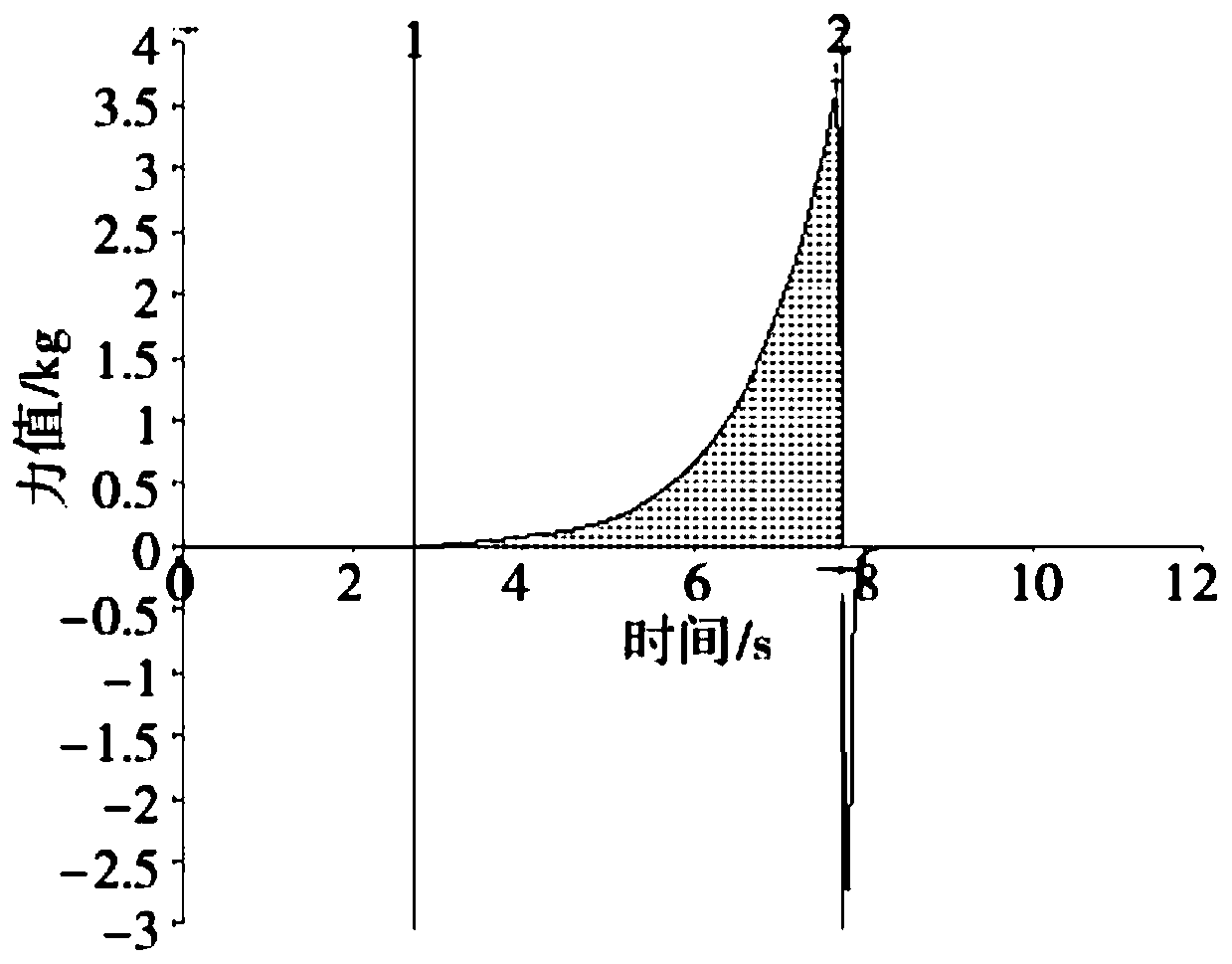

Image

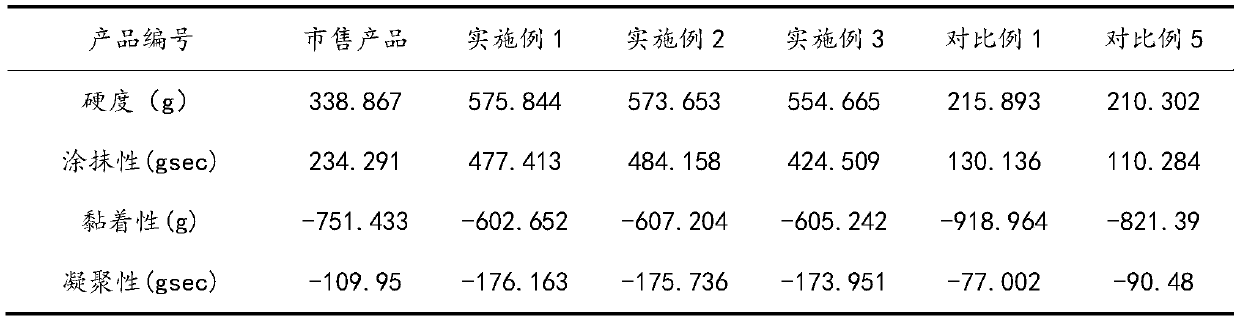

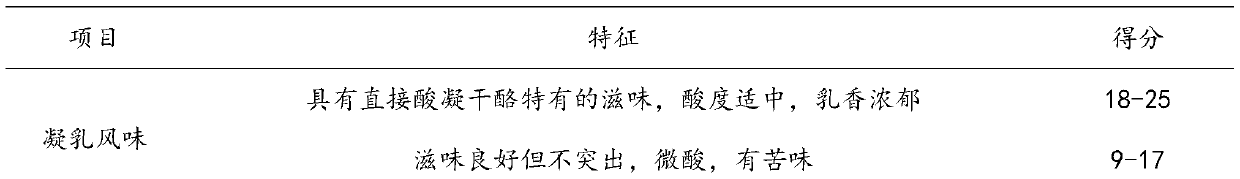

Examples

Embodiment 1

[0027] 1. The protein content of fresh milk is 2.8wt%, the fat is 3.5wt%, the carbohydrate is 4wt%, and the titrated acidity is 18°T. After preheating to 50°C, the milk fat is separated, and the fat content of the skim milk and the cream obtained after separation are 0.05wt% and 40wt% respectively;

[0028] 2. The cream and skim milk prepared in step 1 are mixed until the fat content is 20wt%, prepackaged with polyethylene material and then placed in a water-bath oscillating ultrasonic instrument for processing. The processing time is 10 minutes, and the ultrasonic output power is 400w. The cream temperature before treatment is 20°C, after treatment it is 25°C, and the particle size of fat globules is 10 microns;

[0029] 3. Adjust the acidity of the solution prepared in batches in step 2 at 20°C. Prepare the acetic acid solution with a mass fraction of 3wt%, add it to the cream while stirring, and pause when the pH is 5.8, then use probe-type ultrasonic treatment, the temper...

Embodiment 2

[0033] 1. The protein content of fresh milk is 3.5wt%, the fat is 3.0wt%, the carbohydrate is 4wt%, and the titrated acidity is 18°T. After preheating to 60°C, milk fat is separated, and the fat content of skim milk and cream obtained after separation is 0.05wt% and 50wt% respectively;

[0034] 2. The cream and skim milk prepared in step 1 are mixed until the fat content is 30wt%, prepackaged in a glass bottle, and then placed in a water-bath oscillating ultrasonic instrument for processing. The processing time is 20 minutes, and the output power of the ultrasonic wave is 400w. The temperature of the pre-cream is 25°C, and the temperature after treatment is 30°C, and the particle size of the fat globule is 3 microns;

[0035] 3. Adjust the acidity of the solution prepared in batches in step 2 at 30°C. Configure a citric acid solution with a mass fraction of 10wt%, add it to the cream while stirring, pause when the pH is 6.2, and then use a probe-type ultrasonic treatment. 10...

Embodiment 3

[0039] 1. The protein content of fresh milk is 3.0wt%, the fat is 3.2wt%, the carbohydrate is 5.0wt%, and the titrated acidity is 18°T. After preheating to 55°C, the milk fat is separated, and the fat content of the skim milk and the cream obtained after separation are 0.05wt% and 45wt% respectively;

[0040] 2. The cream and skim milk prepared in step 1 are mixed until the fat content is 25wt%, pre-packaged in a TT tank, and then placed in a water-bath oscillating ultrasonic instrument for processing. The processing time is 15 minutes, and the output power of the ultrasonic wave is 500w. The temperature of the pre-cream is 25°C, and the temperature after treatment is 30°C, and the particle size of the fat globule is 5 microns;

[0041] 3. Adjust the acidity of the solution prepared in batches in step 2 at 25°C. Configure a solution of citric acid and tartaric acid with a mass fraction of 7wt%, add it to the cream while stirring, and pause when the pH is 6.0, and then use a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com