Thermal-wind whirling rapid scenting method of camellia sinensis flowers

A technology of tea tree flower and quick scenting, which is applied in the field of A23F3/34: tea substitutes, can solve the problems of nutrient consumption of tea tree flower, achieve the effect of improving fragrance, promoting drying and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

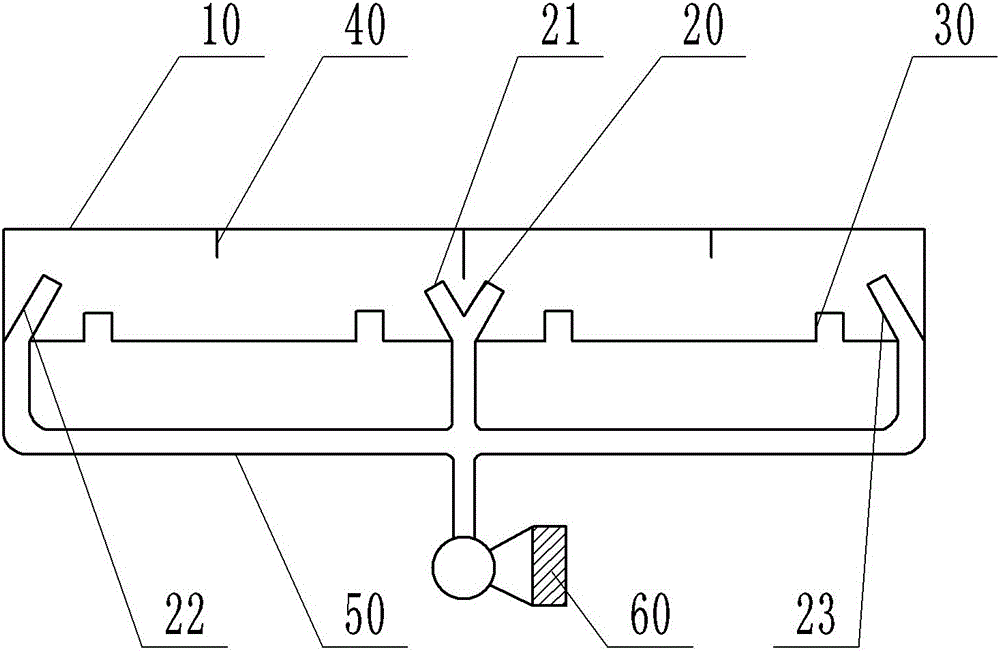

Image

Examples

Embodiment 1

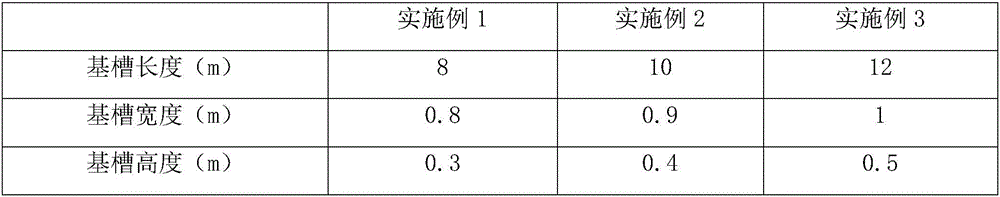

[0034] In concrete implementation process, take embodiment 1 as example, specifically illustrate the method for tea tree flower hot air whirling speed scenting of the present invention, step is as follows:

[0035] The method for tea tree flower hot air whirling speed scenting comprises the following steps:

[0036] The first step is picking, picking the tea tree flowers within 2 days before and after the pollination of the tea tree flowers;

[0037] The second step is to remove impurities and select the residual flowers and rotten flowers;

[0038] The third step is to set up the speed-sensing facility and dig a base tank. The size of the base tank is: 8m in length, 0.8m in width, and 0.3m in height. The injection port, the third injection port and the fourth injection port, the first injection port and the second injection port are arranged in the middle of the side wall, and are respectively located on both sides of the center line of the side wall, and the third injection...

Embodiment 2

[0049] The difference from Example 1 is that the processing data is the data of Example 2 in Table 1, the length of the base groove is 10m, the width of the base groove is 0.9m, the height of the base groove is 0.4m, the thickness of the pattern is 2.5cm, and the air flow The temperature is 47°C, the time for quick scenting is 1.7h, the temperature for curing is 210°C, the time for curing is 1.3min, the temperature for drying is 22°C, the time for drying is 10min, the drying temperature for the first time is 190°C, and the drying time for the first time is 190°C. The drying time is 6.5min, the second drying temperature is 175°C, the second drying time is 6.5min, the third drying temperature is 165°C, the third drying time is 6.5min, the fourth The drying temperature is 155°C, the fourth drying time is 12.5 minutes, and the cooling temperature is 22.5°C.

Embodiment 3

[0051] The difference with Example 1 is that the processing data is the data of Example 3 in Table 1, the length of the base groove is 12m, the width of the base groove is 1m, the height of the base groove is 0.5m, the thickness of the pattern is 3cm, and the airflow temperature is 55°C, the speed scenting time is 1.7h, the finishing temperature is 210°C, the killing time is 1.3min, the airing temperature is 22°C, the airing time is 10min, the first drying temperature is 190°C, the first drying The drying time is 6.5min, the second drying temperature is 175°C, the second drying time is 6.5min, the third drying temperature is 165°C, the third drying time is 6.5min, the fourth drying The temperature is 155°C, the fourth drying time is 12.5min, and the cooling temperature is 22.5°C.

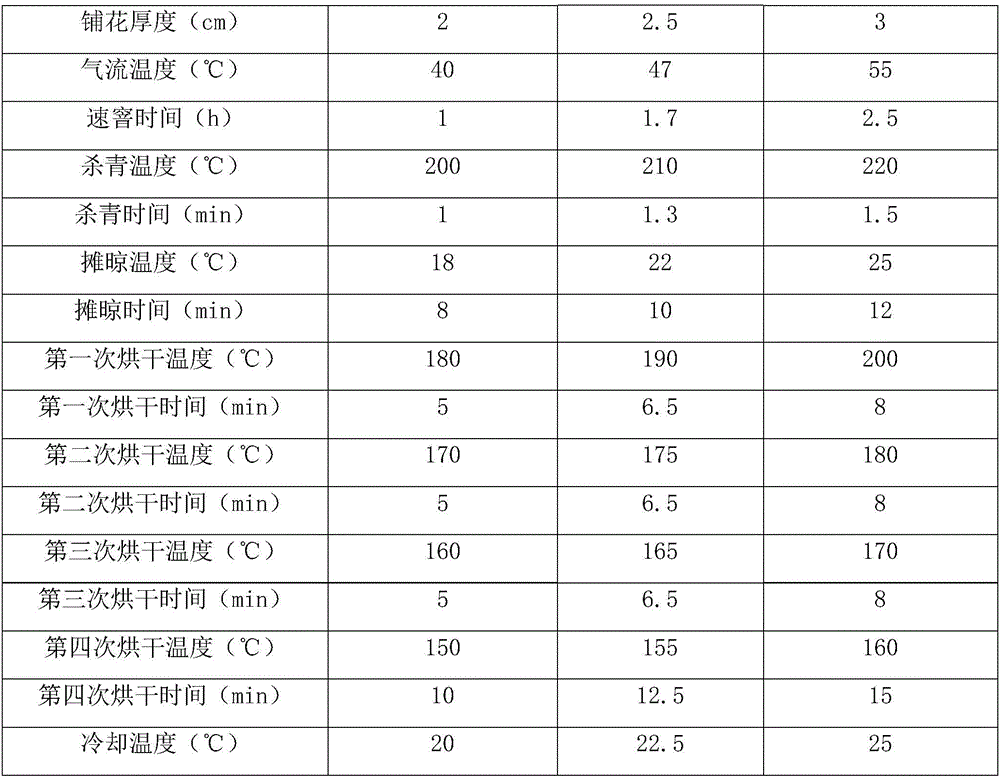

[0052] Following is the amount of loss of nutritive substance in the tea tree flower among the present invention:

[0053] Select 4 frames of tea tree flowers to process at the same time, wherein 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com