Method for radio frequency sterilization of low water activity food

A low-moisture, high-activity technology, applied in food preservation, dairy products, food science, etc., can solve the problems of difficult application of sterilization methods, brown and black color of spices, different flavors, etc., and achieve remarkable sterilization effect, short processing time, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Activation and cultivation of strains: inoculate Escherichia coli strains stored in cryopreservation tubes on nutrient agar plates, culture them at 37°C for 24 hours, transfer them to nutrient broth liquid medium, and shake them at 37°C and 200r / min. Bed culture 14h to the stable period;

[0027] (2) Preparation of bacteria powder: Centrifuge the cultured bacteria solution at 4°C and 6000×g for 5 minutes, discard the supernatant, redissolve the bacteria in sterile normal saline and wash twice by centrifugation. 1ml of sterile normal saline was used to redissolve the obtained bacteria, and the obtained bacterial suspension was dried in a vacuum desiccator; after 3 days, the dried bacteria were ground into powder with a mortar and placed in a polyethylene plastic bottle (previously Sterilization) in sealed standby;

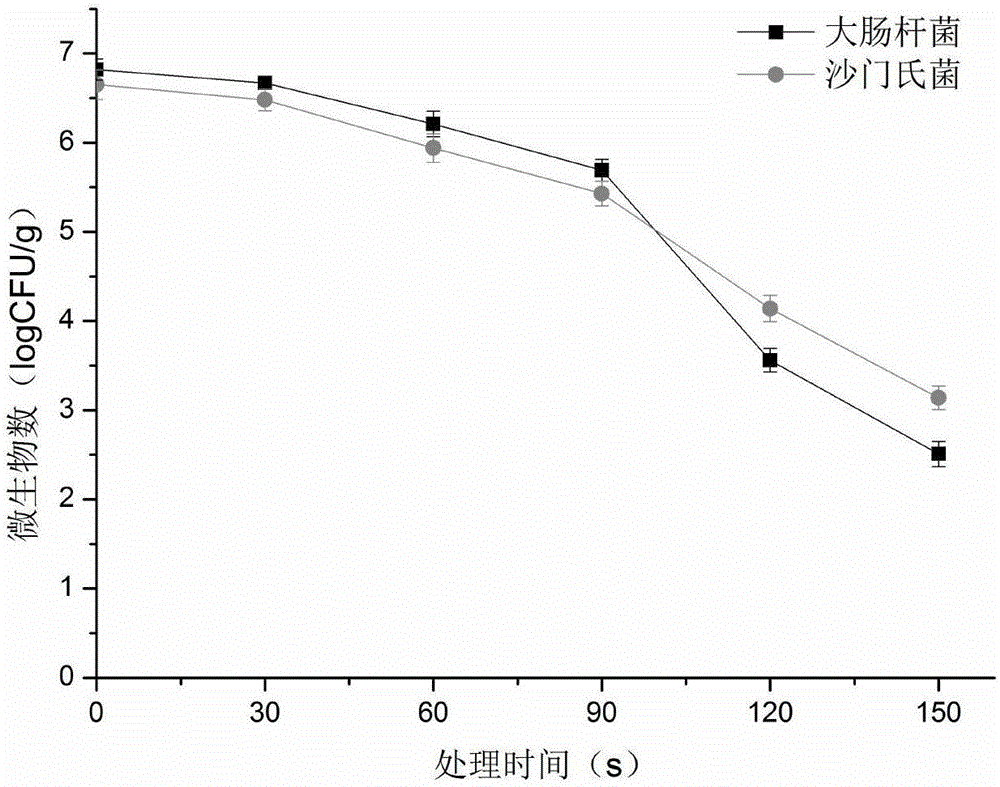

[0028] (3) Inoculation of the sample: mix the bacterium powder and black pepper powder, so that the initial microbial count in the black pepper powder i...

Embodiment 2

[0033] With reference to the method of Example 1, the black pepper powder is sterilized, and the difference is that the inoculation of the sample in step (3): an appropriate amount of bacterial powder is mixed with the black pepper powder, so that the initial microbial count is 6.2log CFU / g;

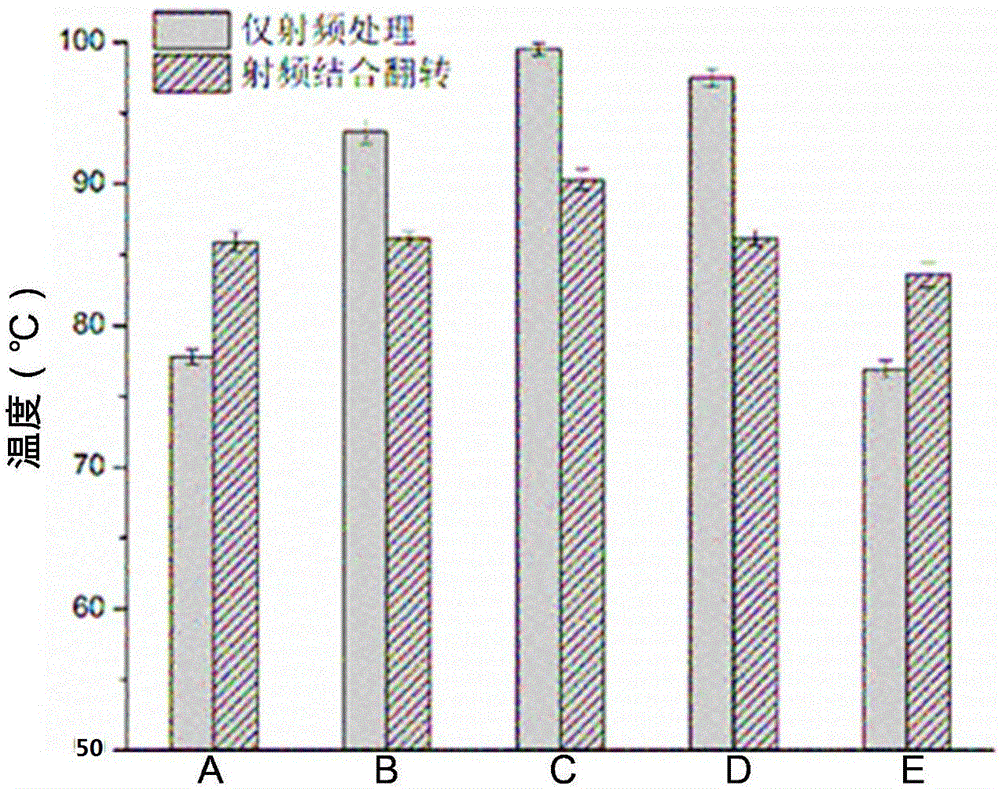

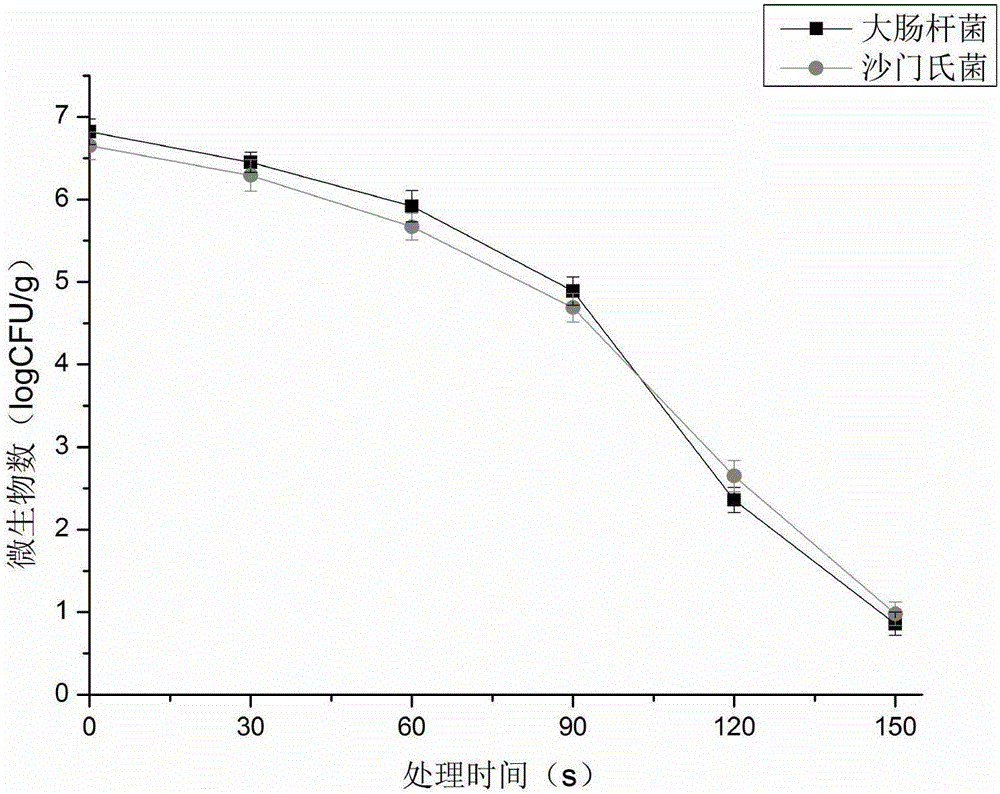

[0034] (4) Radio frequency treatment: Place the sample sealed and packaged in a nano-titanium dioxide antibacterial PE bag in the center of the lower electrode of the radio frequency treatment chamber for sterilization, and turn on the ultraviolet lamp during the radio frequency treatment process. The working frequency of the RF processing device is 27.12MHz, the power of the RF heating system is 6Kw, the distance between the plates is 90mm, the thickness of the sample is 40mm, the processing time is 100s, and the auxiliary temperature in the field strength processing chamber is 55°C. Flip and mix the sample once every 30s to improve the uniformity of radio frequency heating;

[0035] (5...

Embodiment 3

[0038] With reference to the method of embodiment 1, the cabbage powder is sterilized, and the difference is that the inoculation of the sample in step (3): an appropriate amount of bacteria powder is mixed with the cabbage powder, so that the initial microbial count is 7.1log CFU / g;

[0039](4) Radio frequency treatment: Place the sample sealed and packaged in a nano-titanium dioxide antibacterial PE bag in the center of the lower electrode of the radio frequency treatment chamber for sterilization, and turn on the ultraviolet lamp during the radio frequency treatment process. The working frequency of the RF processing device is 27.12MHz, the power of the RF heating system is 9Kw, the distance between the plates is 90mm, the thickness of the sample is 25mm, the processing time is 40s, and the auxiliary temperature in the field intensity processing chamber is 55°C. Invert and mix the sample once every 20s to improve the uniformity of radio frequency heating;

[0040] (5) Cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com