Mineral fodder mold removing agent and preparation method thereof

A mildew remover and mineral technology, applied in the field of mineral feed mildew remover and its preparation, can solve the problems of high nutrient absorption, animal anorexia, poor taste, etc., achieve high mold inhibition rate, eliminate pollution, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

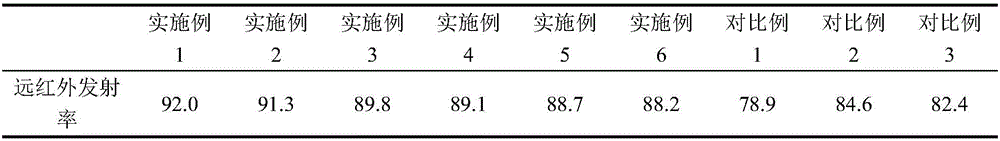

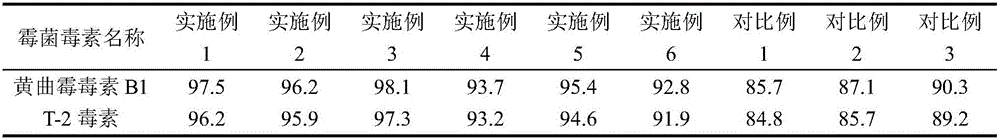

Examples

preparation example Construction

[0019] The steps of the preparation method of above-mentioned mineral feed mildew remover are:

[0020] (a) Carry out particle size downgrading treatment on attapulgite, tourmaline and iron tailings as mineral raw materials, and the particle size after downgrading treatment is 60 mesh (250 microns) to 200 mesh (74 microns);

[0021] (b) uniformly mixing the downgraded attapulgite, tourmaline and iron tailings, and calcining at 600°C for 3 hours to obtain a mineral mixture;

[0022] (c) sorbic acid is dissolved in ethanol, and the quality of ethanol is 8~15 times of sorbic acid quality, obtains sorbic acid solution;

[0023] (d) mixing the mineral mixture calcined in step (b) and the sorbic acid solution obtained in step (c), magnetically stirring, drying, and sieving to obtain a mineral feed mold remover.

[0024] The present invention also protects a feed added with the above-mentioned mineral feed mildew remover. The mineral feed mildew remover is added to the complete fee...

Embodiment 1

[0030] The weight components of the raw materials of the mineral feed mildew remover in this embodiment include: attapulgite 60%, tourmaline 25%, iron tailings 5%, sorbic acid 10%.

[0031] Preparation:

[0032] (a) Carry out particle size downgrading treatment on attapulgite, tourmaline and iron tailings as mineral raw materials, and the particle size after downgrading treatment is 60 mesh (250 microns) to 200 mesh (74 microns);

[0033] (b) uniformly mixing the downgraded attapulgite, tourmaline and iron tailings, and calcining at 600°C for 3 hours to obtain a mineral mixture;

[0034] (c) sorbic acid is dissolved in ethanol, and the quality of ethanol is 10 times of sorbic acid quality, obtains sorbic acid solution;

[0035] (d) mixing the mineral mixture calcined in step (b) and the sorbic acid solution obtained in step (c), magnetically stirring, drying, and sieving to obtain a mineral feed mold remover.

[0036] Method of use: add the above-mentioned feed mold remover ...

Embodiment 2

[0038] The weight components of the raw materials of the mildew remover in this embodiment include: attapulgite 65%, tourmaline 20%, iron tailings 5%, sorbic acid 10%. The preparation and use methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com