Quick-frozen steamed and stuffed bun as well as preparation method and application thereof

A steamed bun and steamed bun skin technology, which is applied in the field of quick-frozen steamed buns and its preparation, can solve the problems of difficulty in proofing, skin embrittlement, steamed bun taste and loss of nutritional components, etc., to improve sensory quality, nutritional value, and water holding rate and high expansion rate, the effect of improving rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

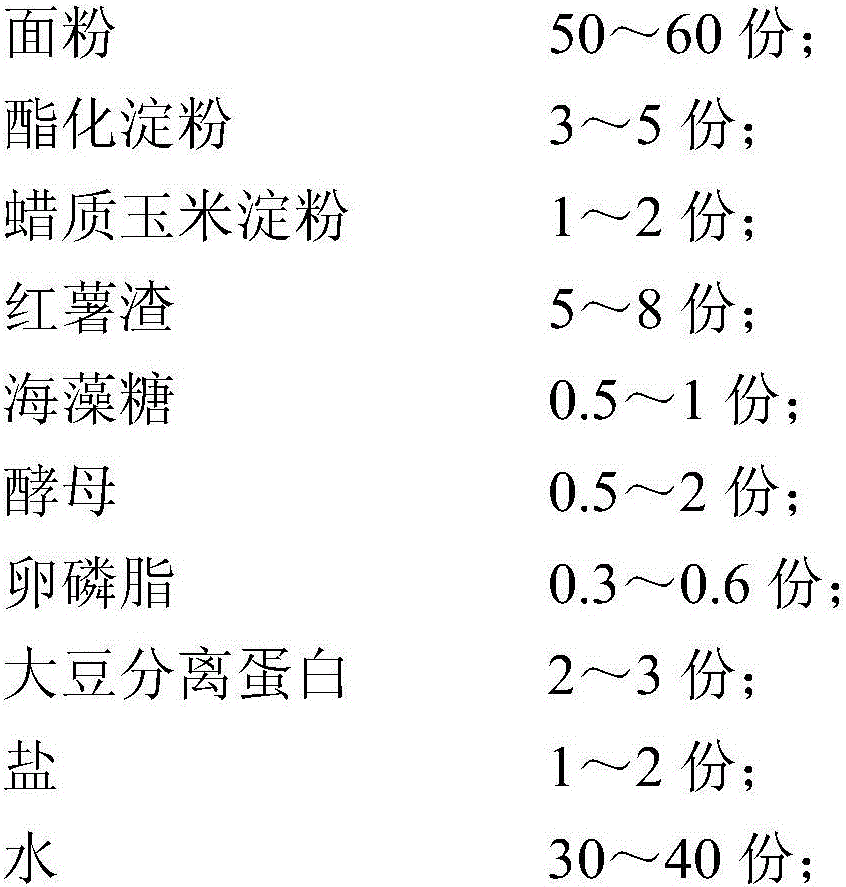

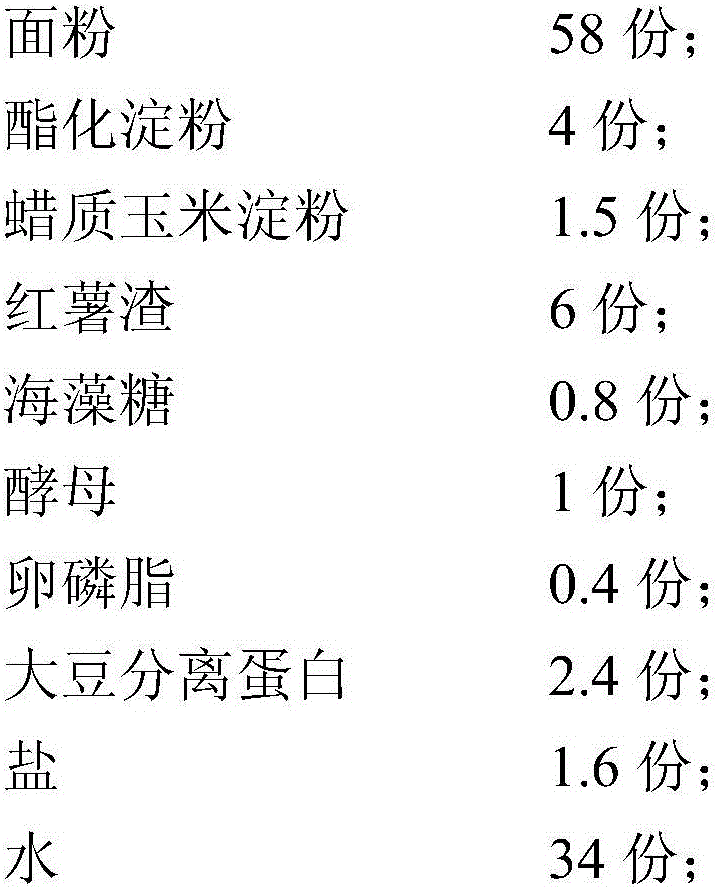

[0041] A kind of quick-frozen steamed stuffed bun, is made up of steamed stuffed bun skin and steamed bun stuffing; Wherein, steamed stuffed bun skin comprises the following components by mass parts:

[0042]

[0043]

[0044] The preparation method of described quick-frozen steamed stuffed bun comprises the steps:

[0045] (1) The components of the bun skin: 58 parts by mass of flour, 4 parts by mass of esterified starch (the mass ratio of octenyl succinic esterified starch and acetate starch is 3:1), 1.5 parts by mass of wax High-quality cornstarch, sweet potato dregs of 6 parts by mass, trehalose of 0.8 parts by mass, yeast powder of 1 part by mass, soybean lecithin of 0.4 parts by mass, soybean protein isolate of 2.4 parts by mass and salt of 1.6 parts by mass were mixed uniformly, and added 34 parts by mass of water were stirred and kneaded. After stirring, the dough was allowed to stand at 30° C. for proofing for 2 hours, and the proofed dough was made into dough s...

Embodiment 2

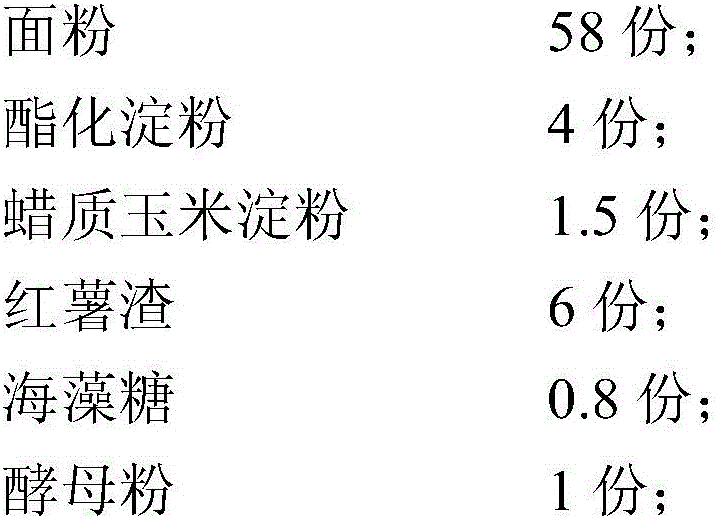

[0050] A kind of quick-frozen steamed stuffed bun, is made up of steamed stuffed bun skin and steamed bun stuffing; Wherein, steamed stuffed bun skin comprises the following components by mass parts:

[0051]

[0052]

[0053] The preparation method of described quick-frozen steamed stuffed bun comprises the steps:

[0054](1) The components of the bun skin: 50 parts by mass of flour, 5 parts by mass of acetate starch, 2 parts by mass of waxy cornstarch, 5 parts by mass of sweet potato residue, 0.5 parts by mass of trehalose, 0.5 parts by mass of trehalose, Yeast powder, 0.6 parts by mass of soybean lecithin, 2 parts by mass of soybean protein isolate and 1 part by mass of salt were mixed evenly, and 30 parts by mass of water were added to stir the dough, and after stirring, the dough was allowed to rest at 20°C for 6 hours. The proofed dough is made into a dough sheet with a thickness of 1.0 cm to obtain the bun skin;

[0055] (2) Add 30 parts by mass of leeks, 10 part...

Embodiment 3

[0059] A kind of quick-frozen steamed stuffed bun, is made up of steamed stuffed bun skin and steamed stuffed bun stuffing; Wherein, steamed stuffed bun skin comprises the following components by mass parts:

[0060]

[0061] The preparation method of described quick-frozen steamed stuffed bun comprises the steps:

[0062] (1) The components of the bun skin: 60 parts by mass of flour, 3 parts by mass of octenyl succinic esterified starch, 1 part by mass of waxy cornstarch, 8 parts by mass of sweet potato residue, 1 part by mass of seaweed Sugar, 2 parts by mass of yeast powder, 0.3 parts by mass of soybean lecithin, 3 parts by mass of soybean protein isolate and 2 parts by mass of salt are mixed evenly, add 40 parts by mass of water to stir and knead the dough, and after stirring, leave the dough for 37 Proof for 1 hour at ℃, make dough sheet with a thickness of 0.5 cm from the proofed dough to obtain bun skin;

[0063] (2) Add 30 parts by mass of pork paste, 15 parts by m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com