Core-shell double-layer microsphere employing poly(p-dioxanone) as core and preparation method and application of core-shell double-layer microsphere

A technology of poly-dioxanone and microspheres, applied in the field of biomedicine, can solve the problems of low burst release and encapsulation rate of single-layer microspheres, inability to control sustained release time, fast degradation time, etc. Good repeatability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

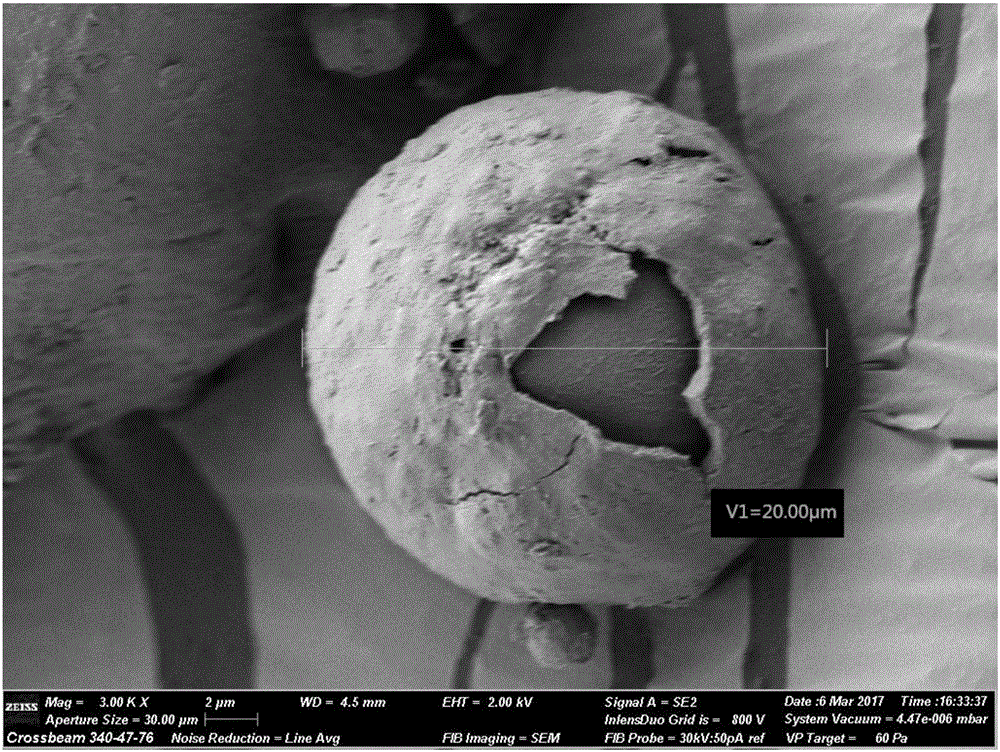

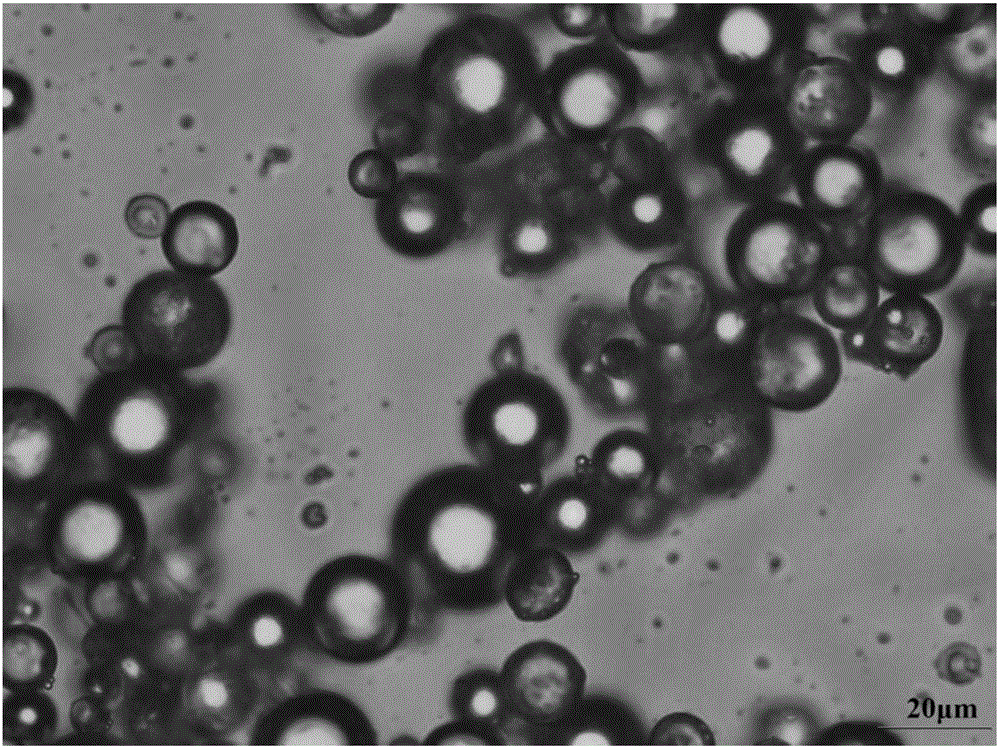

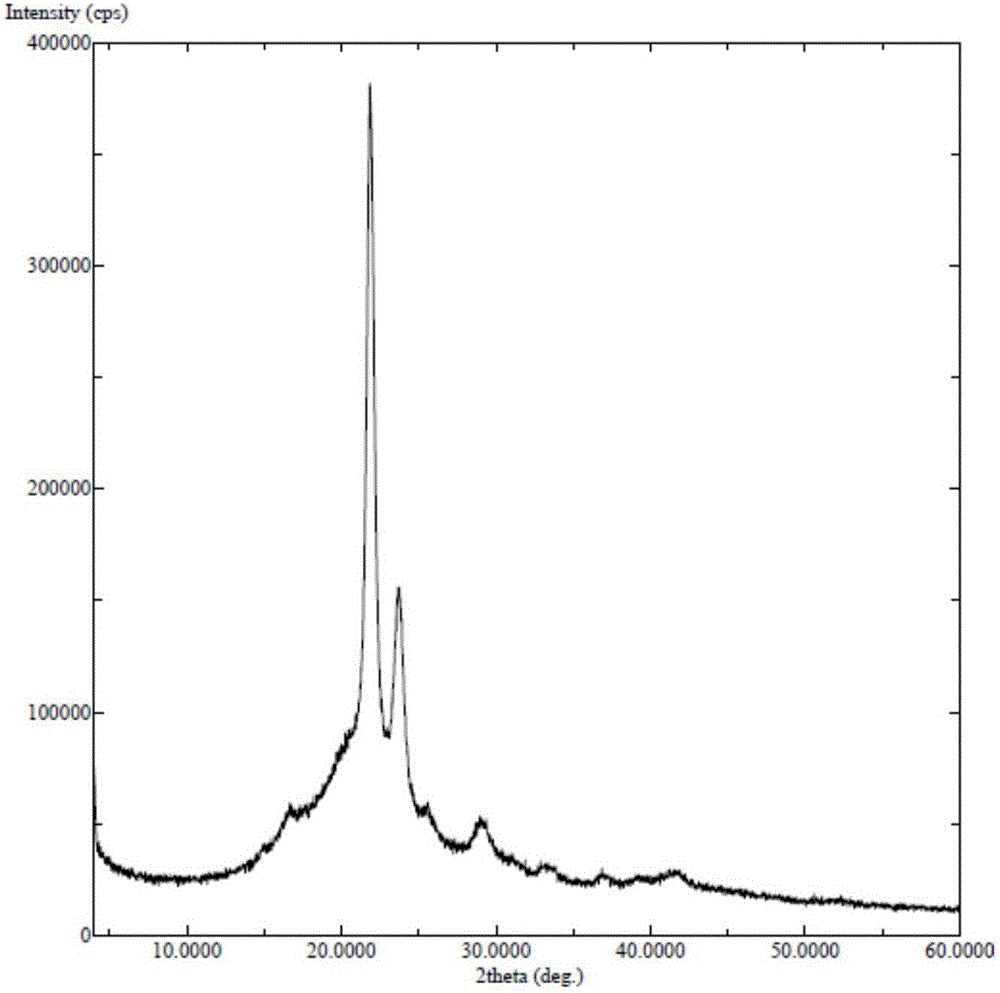

[0034] (1) According to the mass volume ratio (g / mL) of polydioxanone and hexafluoroisopropanol as 8:100, add polydioxanone to hexafluoroisopropanol to the polydioxanone Dioxanone is completely dissolved, and after adding chloroform and stirring, it is added dropwise in the polyvinyl alcohol aqueous solution to obtain a mixed solution. At this time, the volume ratio of hexafluoroisopropanol and chloroform in the mixed solution is 2.5:1. The mass ratio of polydioxanone and polyvinyl alcohol in the aqueous solution of polyvinyl alcohol is 1:1, and the mixed solution is homogeneously stirred at 6000 rpm until the emulsification is complete, and then water solidified with a volume twice the volume of the mixed solution is added. Microspheres, the temperature of the water is 2°C, and an emulsion containing polydioxanone microspheres is prepared;

[0035] (2) Distill the emulsion prepared in step (1) at 55° C. and 0.08 MPa for 30 minutes until the hexafluoroisopropanol and chlorofor...

Embodiment 2

[0041] (1) According to the mass volume ratio (g / mL) of polydioxanone and hexafluoroisopropanol as 1:100, add polydioxanone to hexafluoroisopropanol to the polydioxanone Dioxanone was completely dissolved, then added dichloromethane and stirred, then added dropwise to polyethylene glycol aqueous solution to obtain a mixed solution. At this time, the volume ratio of hexafluoroisopropanol and dichloromethane in the mixed solution was 1:1 , the mass ratio of polydioxanone and polyethylene glycol in aqueous solution of polyethylene glycol is 2:1, the mixed solution is homogeneously stirred at 4000rpm until the emulsification is complete, and the added volume is 3 times of the mixed solution water-cured microspheres, the temperature of the water is 5°C, and an emulsion containing polydioxanone microspheres is obtained;

[0042] (2) Distill the emulsion prepared in step (1) at 55° C. and 0.08 MPa for 50 minutes until the hexafluoroisopropanol and dichloromethane in the emulsion are ...

Embodiment 3

[0048] (1) According to the mass volume ratio (g / mL) of polydioxanone and hexafluoroisopropanol as 4:100, add polydioxanone to hexafluoroisopropanol to the polydioxanone Dioxanone is completely dissolved, and after adding dichloromethane and stirring, it is added dropwise in the polyvinyl alcohol aqueous solution to obtain a mixed solution. At this time, the volume ratio of hexafluoroisopropanol and dichloromethane in the mixed solution is 1:1. The mass ratio of polydioxanone and polyvinyl alcohol in the aqueous polyvinyl alcohol solution is 1:2, and the mixed solution is homogeneously stirred at 7000 rpm until the emulsification is complete, and then water solidified with a volume 4 times that of the mixed solution is added. Microspheres, the temperature of the water is 1°C, and an emulsion containing polydioxanone microspheres is prepared;

[0049] (2) Distill the emulsion prepared in step (1) at 55° C. and 0.06 MPa for 60 minutes until the hexafluoroisopropanol and dichloro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com