Preparation method for hydrogel with stepped hole structure

A technology of stepped holes and structured water, applied in medical science, tissue regeneration, prostheses, etc., can solve problems such as single pore size and pore structure, single composition and structure, mechanics, and biology that cannot meet the needs of articular cartilage repair, etc., to achieve The process is stable, the process is simple and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the stepped pore structure hydrogel of the present embodiment:

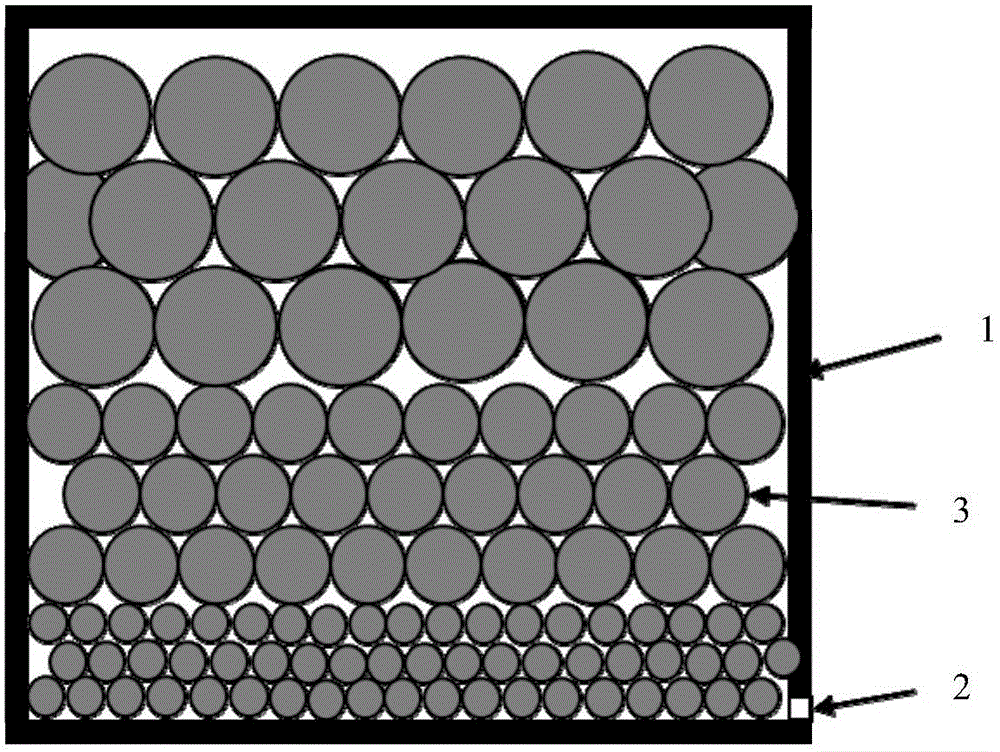

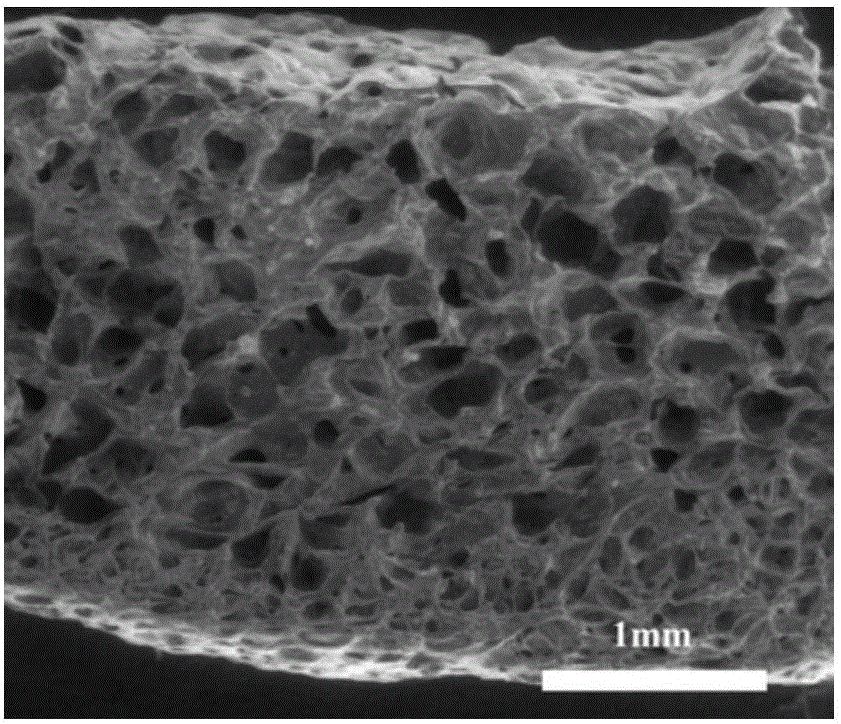

[0027] (1) The mold used in this embodiment is as figure 1 As shown, there is an exhaust port 2 at the bottom of the mold 1, and each NaCl particle 3 with a size range of 50-100 μm, 200-300 μm, and 400-500 μm is weighed 0.1 g each, and the NaCl particles are weighed in the order of small particles first and then large particles. 3. Spread on the mold one by one and compact it; the porogen in the mold is spread in layers according to the particle size, and the holes at the bottom of the mold are conducive to the discharge of air during the molding process.

[0028] (2) Weigh 6g of PVA and pour it into 34mL of DMSO solvent, stir at 110°C for 3 hours to dissolve it completely, then pour the solution into the mold, and shape it under a pressure of 10MPa until there is solution in the hole at the bottom of the mold Release pressure when flowing out;

[0029] (3) Place the mold in a f...

Embodiment 2

[0032] The preparation method of the stepped pore structure hydrogel of the present embodiment:

[0033] (1) Weigh 1 g of NaCl particles with sizes ranging from 1 to 50 μm, 300 to 400 μm, and 500 to 800 μm, respectively, spread the NaCl particles on the mold in the order of small particles first and then large particles and compact them;

[0034] (2) Weigh 6g of PVA and pour it into 30mL of DMSO solvent, stir at 110°C for 2 hours to dissolve it completely, then pour the solution into the mold, and shape it under a pressure of 5MPa until there is solution in the hole at the bottom of the mold Release pressure when flowing out;

[0035] (3) Place the mold in a freezer for 8 hours, then thaw it at room temperature for 16 hours, and cycle 9 times like this to make cross-linking between PVA molecules;

[0036] (4) Take the hydrogel out of the mold and put it into deionized water for stirring, and change the water every 2 hours until the NaCl particles are fully dissolved to obtain...

Embodiment 3

[0039] The preparation method of the stepped pore structure hydrogel of the present embodiment:

[0040] (1) Weigh 1 g of sucrose granules with sizes ranging from 1 to 50 μm, 300 to 400 μm, and 500 to 800 μm respectively, spread the sucrose granules on the mold and compact them sequentially in the order of small granules first and then large granules;

[0041] (2) Weigh 6g of PLGA and pour it into 40mL of DMSO solvent, stir at 110°C for 3 hours to dissolve it completely, then pour the solution into the mold, and shape it under a pressure of 20MPa until there is solution in the hole at the bottom of the mold Release pressure when flowing out;

[0042] (3) Place the mold in a freezer for 8 hours, then thaw it at room temperature for 16 hours, and cycle 10 times like this to make cross-linking between PLGA molecules;

[0043] (4) The hydrogel was taken out from the mold and put into deionized water for stirring, and the water was changed every 2 hours until the sucrose particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com