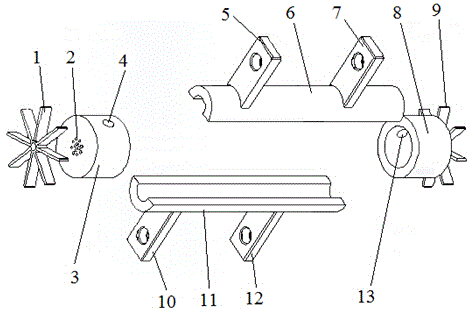

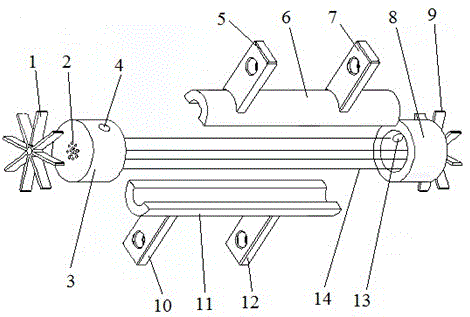

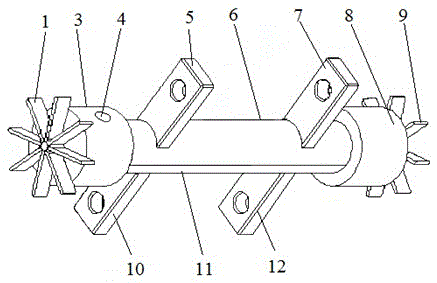

Multi-channel nerve repair catheter and mold with tissue inductive function

A nerve repair and inductive technology, applied in the medical field, can solve problems such as easy inactivation, affect nerve regeneration, biocompatibility differences, etc., achieve good degradability and biocompatibility, repair peripheral nerve defects, and mechanical strength. guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] According to the mass ratio of 1:5, salidroside and chitosan were respectively taken, mixed uniformly, and chitosan-coated salidroside microspheres were prepared by using the tripolyphosphate method; the microspheres were treated with 1% genipin Cross-link at 37°C for 1 hour, vacuum freeze-dry for later use; dissolve polylactic acid-polyglycolic acid copolymer in chloroform to obtain a saturated solution, add 10 mg of prepared microspheres, stir with a magnetic stirrer at 50 rpm for 2 hours, and volatilize in a fume hood Remove chloroform, centrifuge at 4°C and 15,000rpm for 10 minutes, add appropriate amount of distilled water to disperse to obtain compound salidroside sustained-release microspheres, dry at room temperature for later use; use light microscope, laser particle size analyzer and scanning electron microscope to evaluate compound salidroside respectively Morphology, particle size characteristics and characterization of sustained-release microspheres; in vitr...

Embodiment 2

[0073]According to the mass ratio of 1:10, salidroside and chitosan were respectively taken, mixed evenly, and chitosan-coated salidroside microspheres were prepared by using the tripolyphosphate method; the microspheres were treated with 1% genipin Cross-link at 37°C for 1 hour, vacuum freeze-dry for later use; dissolve polylactic acid-polyglycolic acid copolymer in chloroform to obtain a saturated solution, add 10 mg of the prepared microspheres, stir with a magnetic stirrer at 60 rpm for 2 hours, and place in a fume hood Remove chloroform in the medium, centrifuge at 4°C and 15000rpm for 10min, add appropriate amount of distilled water to disperse to obtain composite salidroside sustained-release microspheres, dry at room temperature for later use; use light microscope, laser particle size analyzer and scanning electron microscope to evaluate composite rhodiola respectively Morphology, particle size characteristics and characterization of glucoside sustained-release microsph...

Embodiment 3

[0075] According to the mass ratio of 1:50, salidroside and chitosan were respectively taken, mixed evenly, and chitosan-coated salidroside microspheres were prepared by using the tripolyphosphate method; the microspheres were treated with 1% genipin Cross-link at 37°C for 1 hour, vacuum freeze-dry for later use; dissolve polylactic acid-polyglycolic acid copolymer in chloroform to obtain a saturated solution, add 10 mg of microspheres, stir with a magnetic stirrer at 55 rpm for 2 hours, and volatilize in a fume hood Remove chloroform, centrifuge at 4°C and 15,000 rpm for 10 minutes at high speed, add appropriate amount of distilled water to disperse to obtain composite salidroside sustained-release microspheres, dry at room temperature for later use; use light microscope, laser particle size analyzer and scanning electron microscope to evaluate composite rhodiola Morphology, particle size characteristics and characterization of glucoside sustained-release microspheres; in vitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com