Reverse osmosis membrane containing aquaporins and preparation method of reverse osmosis membrane

An aquaporin and reverse osmosis membrane technology, applied in the field of water treatment, can solve the problem of weak binding force between the support membrane and the active membrane, and achieve the effects of long service life, good stability and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

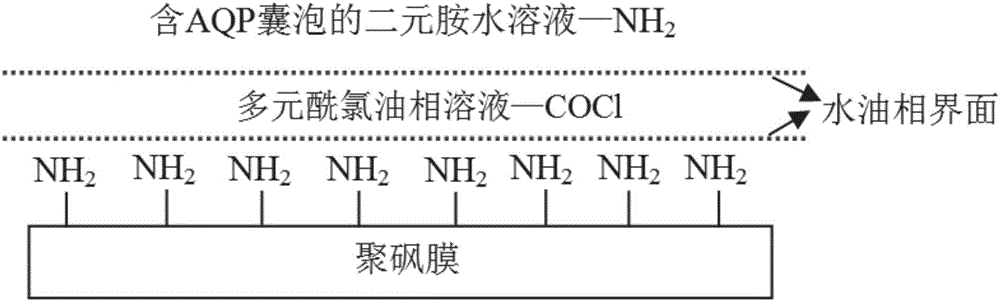

Method used

Image

Examples

Embodiment 1

[0036]Spray dichloromethane evenly on the surface of polysulfone support membrane to dissolve the upper surface of polysulfone, then evenly spray 1,4-dichloromethoxybutane and catalyst SnCl 4 , place the membrane on a shaker and shake slightly, react at room temperature (25° C.) for 6 hours, and obtain a chloromethylated polysulfone membrane after post-treatment.

[0037] At room temperature (25° C.), soak the chloromethylated polysulfone membrane in ethylenediamine for a reaction time of 60 minutes, and obtain an ammoniated polysulfone membrane after post-treatment.

[0038] Prepare an aqueous solution of m-phenylenediamine with a mass fraction of 5.5wt%, 0.1mg / mL aquaporin vesicles, 0.2wt% NaOH, and 0.1wt% SDS, add 0.05mol of 4-dimethylaminopyridine, and stir for 10min .

[0039] Soak the ammoniated polysulfone membrane in 0.1% trimesoyl chloride-n-hexane solution for 3 minutes, take out and soak in the m-phenylenediamine aqueous solution of the vesicles containing aquapori...

Embodiment 2

[0041] Spray dichloromethane evenly on the surface of polysulfone support membrane to dissolve the upper surface of polysulfone, then evenly spray trimethylchlorosilane and catalyst SnCl 4 , add paraformaldehyde, place the membrane on a shaker and shake slightly, react at 35°C for 12 hours, and obtain a chloromethylated polysulfone membrane after post-treatment.

[0042] At room temperature (25° C.), soak the chloromethylated polysulfone membrane in ethylenediamine for a reaction time of 60 minutes, and obtain an ammoniated polysulfone membrane after post-treatment.

[0043] Prepare an aqueous solution of m-phenylenediamine with a mass fraction of 5.5wt%, 0.1mg / mL aquaporin vesicles, 0.2wt% NaOH, and 0.1wt% SDS, add 0.05mol of 4-dimethylaminopyridine, and stir for 10min .

[0044] Soak the ammoniated polysulfone membrane in 0.1wt% trimesoyl chloride-n-hexane solution for 3 minutes, take it out and soak it in the m-phenylenediamine aqueous solution of the vesicles containing a...

Embodiment 3

[0046] Spray dichloromethane evenly on the surface of polysulfone supporting membrane to dissolve the upper surface of polysulfone, then evenly spray chloromethyl alkyl ether and catalyst anhydrous zinc oxide, place the membrane on an oscillator for slight vibration, and react at 40°C After 5 hours, the chloromethylated polysulfone membrane was obtained after post-treatment.

[0047] At room temperature (25° C.), soak the chloromethylated polysulfone membrane in ethylenediamine for a reaction time of 60 minutes, and obtain an ammoniated polysulfone membrane after post-treatment.

[0048] Prepare an aqueous solution of m-phenylenediamine with a mass fraction of 5.5wt%, 0.1mg / mL aquaporin vesicles, 0.2wt% NaOH, and 0.1wt% SDS, add 0.05mol of 4-dimethylaminopyridine, and stir for 10min .

[0049] Soak the ammoniated polysulfone membrane in 0.1wt% trimesoyl chloride-n-hexane solution for 3 minutes, take it out and soak it in the m-phenylenediamine aqueous solution of the vesicles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com