Silver phosphate-titanium dioxide/potassium salt tetratitanate compound and preparation method thereof and application

A technology of titanium dioxide and potassium tetratitanate, which is applied in the fields of chemical instruments and methods, chemical/physical processes, special compound water treatment, etc., can solve the problem of low solar energy utilization rate, low efficiency of photogenerated electron and hole separation of potassium tetratitanate, Catalytic activity limitations and other issues, to achieve the effect of simple preparation method, improve catalytic degradation efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

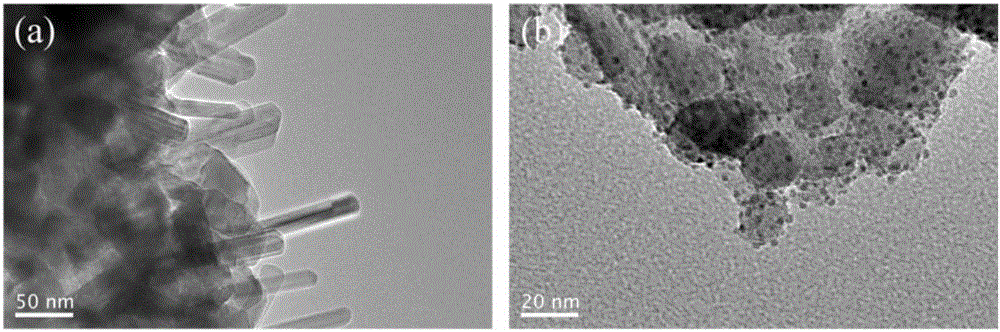

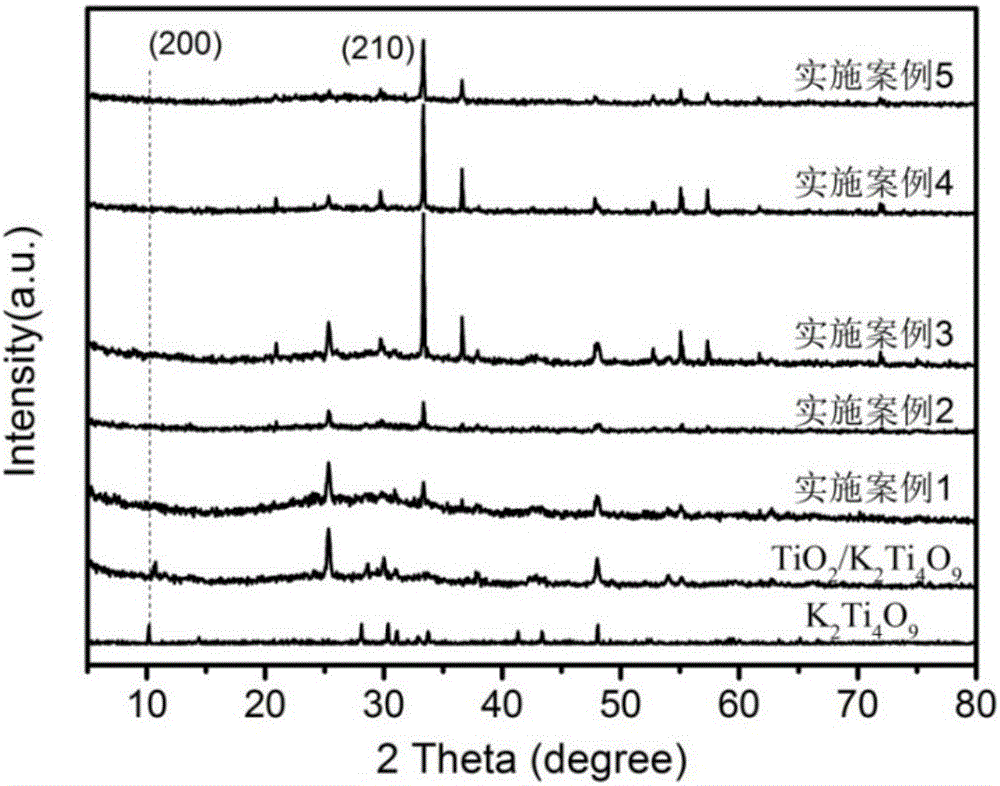

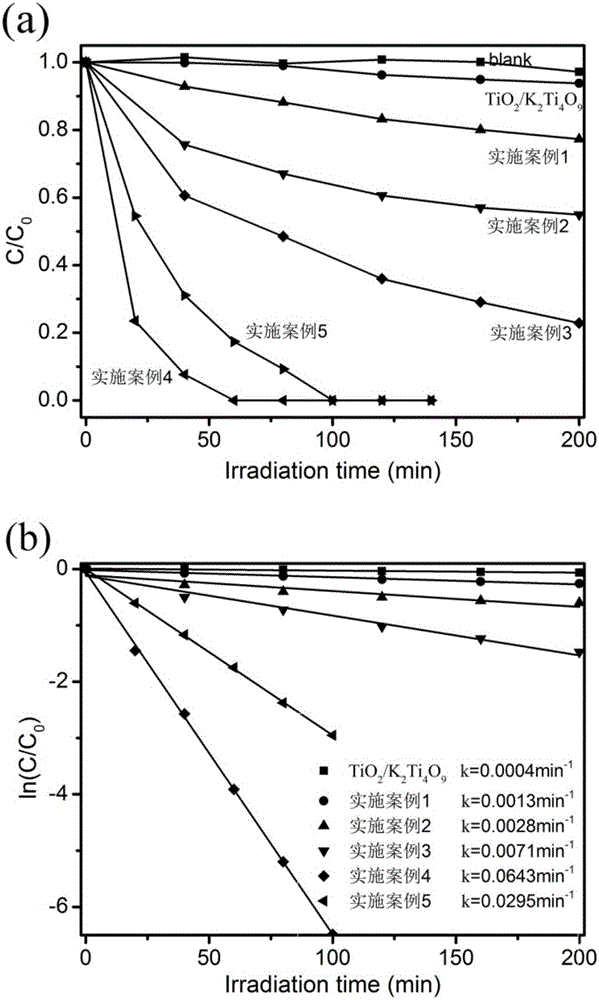

[0027] In the first step, 1g K 2 Ti 4 o 9 Disperse with 3g of isopropyl titanate in 40mL of ethanol and stir for 4h, then dry the mixed solution to obtain a white solid, then grind the obtained white solid, put it into a muffle furnace for calcination, the calcination temperature is 450°C, keep warm The time is 4h, the heating rate is 2°C / min, and finally TiO 2 / K 2 Ti 4 o 9 Complex.

[0028] In the second step, 500mg TiO 2 / K 2 Ti 4 o 9 The complex was ultrasonically dispersed in 50 mL of water, 125 mg of AgNO 3 Dubbed the solution which was slowly added and stirred for 30min.

[0029] In the third step, 63mg NaH 2 PO 4 The prepared solution was slowly added dropwise to the solution in the second step, then stirred for 12 hours, centrifuged and washed several times with deionized water, and finally the product was dried to obtain Ag 3 PO 4 -TiO 2 / K 2 Ti 4 o 9 Complex.

[0030] The fourth step, weigh 20mg Ag 3 PO 4 -TiO 2 / K 2 Ti 4 o 9 The complex wa...

Embodiment 2

[0034] In the first step, 1g K 2 Ti 4 o 9 and 3 g of isopropyl titanate were dispersed in 40 mL of ethanol solution and stirred for 4.5 h, then the mixed solution was dried to obtain a white solid, which was ground and then calcined in a muffle furnace at a temperature of 450 ℃, the holding time is 5h, the heating rate is 2℃ / min, and finally TiO 2 / K 2 Ti 4 o 9 Complex.

[0035] In the second step, 500mg TiO 2 / K 2 Ti 4 o 9 The complex was ultrasonically dispersed in 50 mL of water, 250 mg of AgNO 3 Dubbed solution was added slowly, and stirred for 35min.

[0036] In the third step, 125mg NaH 2 PO 4 The prepared solution was slowly added dropwise to the solution in the second step, then stirred for 12 hours, centrifuged and washed with deionized water several times, and finally the product was oven-dried at 60°C to obtain Ag 3 PO 4 -TiO 2 / K 2 Ti 4 o 9 Complex.

[0037] The fourth step, weigh 20mg Ag 3 PO 4 -TiO 2 / K 2 Ti 4 o 9 The complex was placed ...

Embodiment example 3

[0041] In the first step, 1 g of K prepared by high-temperature solid-phase method 2 Ti 4 o 9 Disperse 2g of isopropyl titanate in 40mL ethanol solution and stir for 5h, then dry the mixed solution to obtain a white solid, grind the obtained white solid, and then put it into a muffle furnace for calcination at a temperature of 500°C , the holding time is 4.5h, the heating rate is 2℃ / min, and finally TiO 2 / K 2 Ti 4 o 9 Complex.

[0042] In the second step, 500mg TiO 2 / K 2 Ti 4 o 9 The complex was ultrasonically dispersed in 50 mL of water, 500 mg of AgNO 3 Dubbed into the solution which was slowly added, and stirred for 40min.

[0043] In the third step, 250mg NaH 2 PO 4 The prepared solution was slowly added dropwise to the solution in the second step, then stirred for 12 hours, centrifuged and washed several times with deionized water, and finally the product was dried to obtain Ag 3 PO 4 -TiO 2 / K 2 Ti 4 o 9 Complex.

[0044] The fourth step, weigh 20mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com