Preparation method of ZTA particle enhanced steel-based composite liner plate based on chemical activation treatment

A technology of activation treatment and particle reinforcement, which is applied in the field of preparation of wear-resistant materials, can solve the problems of reinforcement, poor binding between ZTA particles and iron base, and ZTA ceramic particles cannot be used to enhance interface bonding, improve bonding strength, and improve The effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Ball mill liner

[0024] 1) Mix titanium powder and inorganic salt, add ZTA particles and stir evenly to carry out high-temperature salt bath plating. The temperature of high-temperature salt bath is 750 ° C, and keep warm for 15 minutes to obtain a uniform coating; wherein, the mass ratio of titanium powder to inorganic salt is 10%, The mass fraction of ZTA ceramic particles in salt bath plating is 80%.

[0025] 2) Put the titanium-plated ZTA particles into the chemical plating solution, stir with a magnetic stirrer and heat to 70°C for 2 hours to obtain a nickel layer;

[0026] 3) Sinter the coated ZTA particles, raise the temperature from room temperature to 1200°C at a heating rate of 10-15°C / min, then raise the temperature to 1400°C at a heating rate of 5-8°C / min and sinter for 1 hour, then cool with the furnace , ZTA particles are interconnected to form a pore-like prefabricated body;

[0027] 4) Fix the prefabricated body in the sand mold, and then u...

Embodiment 2

[0028] Example 2: Roller Mill Liner

[0029] 1) Mix titanium powder and inorganic salt, add ZTA particles and stir evenly to carry out salt bath plating. The mass fraction of ZTA ceramic particles in bath plating is 80%.

[0030] 2) Put the titanium-plated ZTA particles into the chemical plating solution, stir with a magnetic stirrer and heat to 90°C for 4 hours to obtain a nickel layer;

[0031] 3) Sinter the coated ZTA particles, raise the temperature from room temperature to 1200°C at a heating rate of 10-15°C / min, then raise the temperature to 1400°C at a heating rate of 5-8°C / min and sinter for 1 hour, then cool with the furnace , ZTA particles are interconnected to form a pore-like prefabricated body;

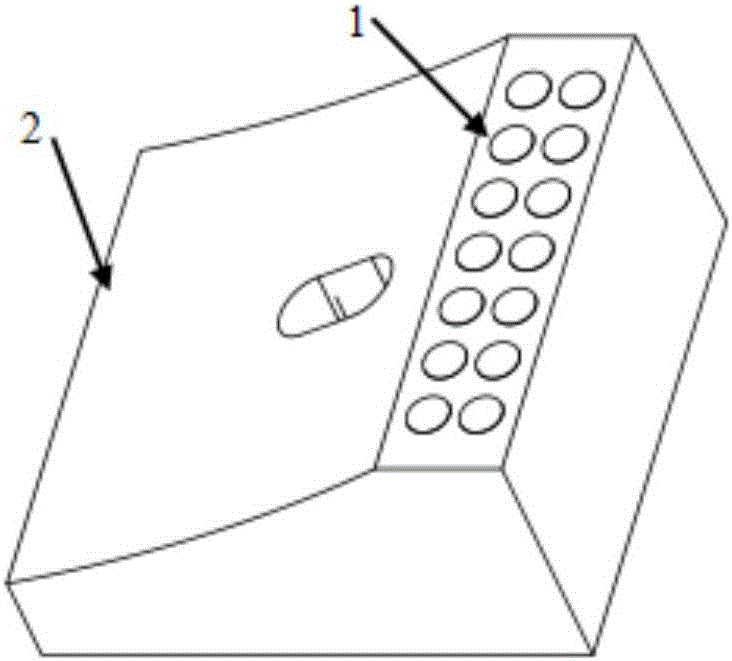

[0032] 4) Fix the prefabricated body in the sand mold, and then use the cast infiltration process to pour the molten metal of the steel matrix material, and obtain figure 1 The ZTA particle reinforced steel matrix composite liner is shown.

Embodiment 3

[0033] Example 3: column mill liner

[0034] 1) Mix titanium powder and inorganic salt, add ZTA particles and stir evenly to carry out salt bath plating. The mass fraction of ZTA ceramic particles in bath plating is 80%.

[0035] 2) Put the titanium-plated ZTA particles into the chemical plating solution, stir with a magnetic stirrer and heat to 80° C. for 6 hours to obtain a nickel layer;

[0036] 3) Sinter the coated ZTA particles, raise the temperature from room temperature to 1200°C at a rate of 10-15°C / min, and then increase the rate of temperature to 1400°C at a rate of 5-8°C / min for sintering for 1 hour, then cool with the furnace , ZTA particles are interconnected into a pore-like prefabricated body.

[0037] 4) Fix the prefabricated body in the sand mold, and then use the cast infiltration process to pour the molten metal of the steel matrix material, and obtain figure 1 The ZTA particle reinforced steel matrix composite liner is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com