Preparation method for 3DOM WO3 material with adjustable pore size and application thereof

A 3DOMWO3, aperture technology, applied in material resistance, tungsten oxide/tungsten hydroxide, etc., to achieve high sensitivity, high selectivity, and efficient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

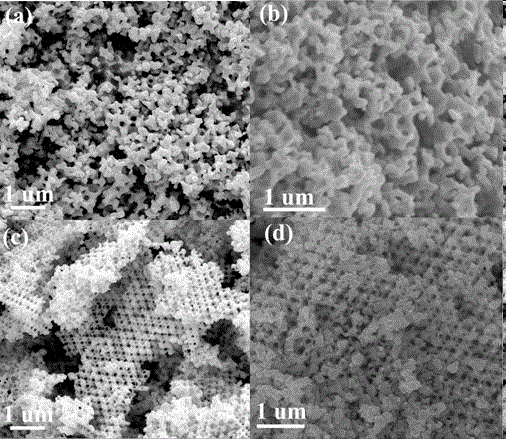

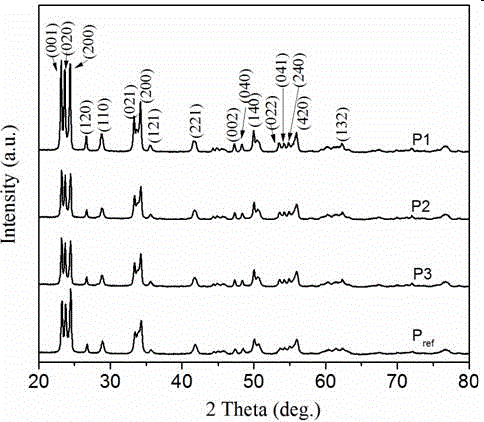

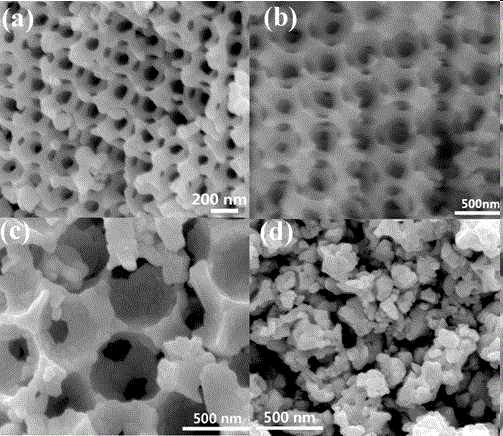

[0033] A 3DOM WO with adjustable aperture 3 The preparation method of material comprises the following steps:

[0034] S1. Preparation of polystyrene template:

[0035] S1.1. Add 200 mL of deionized water into the four-necked flask, then add 5 mL of styrene purified by vacuum distillation into the flask, and then heat it in an oil bath, while passing Nitrogen protection gas, remove the air in the four-necked flask, when the reaction temperature reaches 70 °C, add 0.15 g K 2 S 2 o 8 , reacted for 8 h, after the reaction, the polystyrene mother liquor with a particle size of 340 nm was obtained;

[0036] S1.2. Ultrasonicate the polystyrene mother liquor for 10 min to obtain a uniform emulsion, then centrifuge at 3000 rpm for 10 h, and then place it in a 60°C oven for 12 h to obtain a polystyrene template;

[0037] S2. Dissolve ammonium tungstate in 30 wt% hydrogen peroxide to obtain a precursor solution with a concentration of 2.4 mol / L in terms of tungsten. Immerse the pol...

Embodiment 2

[0040] The difference from Example 1 is that the concentration of the precursor solution in S2 is 4.8 mol / L.

Embodiment 3

[0042] The difference from Example 1 is that the concentration of the precursor solution in S2 is 9.6 mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com