Detergent for ammonium diuranate, and method for deflorinating ammonium diuranate

A technology of ammonium diuranate and detergent, which is applied in chemical instruments and methods, uranium compounds, inorganic chemistry, etc., can solve the problems of oxide film passivation, corrosion damage, and reducing the safe operation and life of nuclear fuel, so as to reduce the Blunt, reduced corrosion damage, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A detergent for ammonium diuranate comprising ammonium carbonate and hydrogen peroxide.

[0027] In this scheme, ammonium carbonate is used as a buffer to prevent the dissolution of ammonium diuranate; hydrogen oxide and UO 2 2- Strong ion coordination ability, can replace F ion in ammonium diuranate to achieve the technical effect of washing and defluorination. That is, the program provides a solute solution including ammonium carbonate and hydrogen peroxide as a detergent, which contains and UO 2 2- The ionic components with strong coordination ability can effectively remove the fluorine ions in ADU by washing the ADU filter cake with a certain washing method to reduce the fluorine content in ADU. The mass fraction of fluorine in ADU after the traditional ADU defluorination method is About 3%, the mass fraction of fluorine in the ADU can be reduced to 0.7% or less after washing by the detergent, and the buffer provides technical guarantee for the optimization of th...

Embodiment 2

[0029] This embodiment is further limited on the basis of Example 1: the detergent is mixed by ammonium carbonate solution and hydrogen peroxide solution, and the volume ratio ratio of ammonium carbonate solution and hydrogen peroxide solution is 1.5 to 3, the mass of ammonium carbonate solution The percentage concentration is 8%-10%, and the mass percentage concentration of the hydrogen peroxide solution is 3%-5%. In this scheme, the hydrogen peroxide solution is the aqueous solution of hydrogen peroxide. The limitation of the amount of ammonium carbonate and hydrogen peroxide in the detergent can make the detergent provided in this case able to ensure the stable existence of ammonium diuranate in the washing environment. Obtain higher washing defluorination ability.

[0030] As a preferred proportioning mode, the volume ratio ratio of the ammonium carbonate solution and the hydrogen peroxide solution is 2. Using the detergent provided by this solution, after one wash, the m...

Embodiment 3

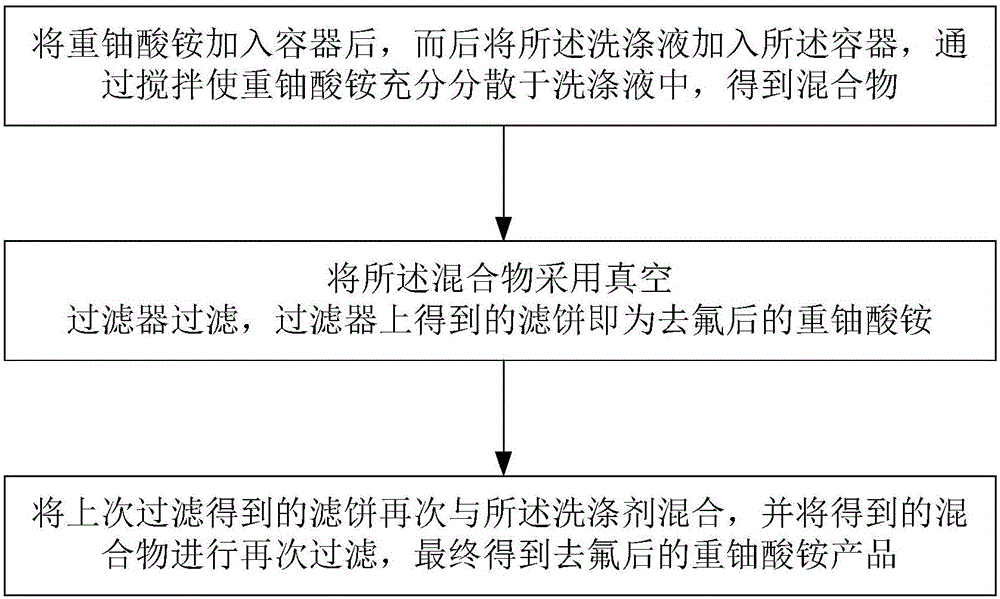

[0032] Such as figure 1 As shown, this embodiment provides a method for defluorination of sodium oleate: at the same time, the present invention also discloses a method for defluorination of ammonium diuranate, which uses any of the detergent solutions provided above for A defluorination wash for ammonium diuranate comprising the following steps in sequence:

[0033] S1. Mix ammonium diuranate with the detergent, so that the ammonium diuranate is dispersed in the detergent to obtain a mixture A;

[0034] S2. The mixture A is filtered, and the filter cake obtained by filtering is ammonium diuranate after defluorination.

[0035] The above method provided in this case is simple to operate and can effectively wash out the fluoride ions in ADU. The fluorine content in ADU can be reduced to 0.7% after washing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com