Special scale inhibitor for integrated membrane system

A scale inhibitor and integrated membrane technology, applied in the field of scale inhibitors, can solve the problems of high price, no effect of antibacterial and scale inhibition, and water quality hazards, and achieve easy biodegradation, inhibition of slime deposition, and inhibition of insoluble salts The effect formed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

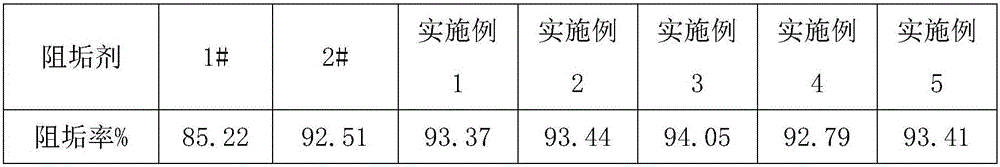

Examples

Embodiment 1

[0018] A special scale inhibitor for integrated membrane system, the components are calculated by weight: 15 parts of tannic acid, 40 parts of polyaspartic acid, 20 parts of vinyl methyl ether / maleic anhydride copolymer, dodecyl dimethyl 5 parts of benzyl ammonium chloride and 20 parts of distilled water.

[0019] The preparation method is as follows: add distilled water, tannic acid, polyaspartic acid, vinyl methyl ether / maleic anhydride copolymer, and dodecyldimethylbenzyl ammonium chloride into the reaction kettle in sequence, and stir at room temperature , the stirring speed of the kettle is 100r / min, and the stirring time is 1.5h, and the finished product is obtained.

Embodiment 2

[0021] A special scale inhibitor for integrated membrane system, the components are calculated by weight: 35 parts of tannic acid, 20 parts of polyaspartic acid, 10 parts of vinyl methyl ether / maleic anhydride copolymer, dodecyl dimethyl 10 parts of benzyl ammonium chloride and 25 parts of distilled water.

[0022] The preparation method is as follows:

[0023] Add distilled water, tannic acid, polyaspartic acid, vinyl methyl ether / maleic anhydride copolymer, and dodecyldimethylbenzyl ammonium chloride into the reaction kettle in sequence, stir at room temperature, and stir the kettle The speed is 150r / min, the stirring time is 1.7h, and the finished product is obtained.

Embodiment 3

[0025] A special antiscalant for integrated membrane system, the components are calculated by weight: 30 parts of tannic acid, 30 parts of polyaspartic acid, 15 parts of vinyl methyl ether / maleic anhydride copolymer, dodecyl dimethyl 2 parts of benzyl ammonium chloride and 23 parts of distilled water.

[0026] The preparation method is as follows:

[0027] Add distilled water, tannic acid, polyaspartic acid, vinyl methyl ether / maleic anhydride copolymer, and dodecyldimethylbenzyl ammonium chloride into the reaction kettle in sequence, stir at room temperature, and stir the kettle The speed is 130r / min, the stirring time is 2h, and the finished product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com