Anti-skid rainproof mist-resistant asphalt pavement material and preparation method thereof

A technology of asphalt pavement and asphalt gravel, which is applied in the field of pavement materials, can solve the problems of insufficient contact between tires and pavement, poor anti-skid performance of asphalt concrete, and affecting the sight of vehicles, so as to shorten production and construction time and improve durability. Abrasion resistance and compressive strength, and the effect of improving the anti-slip coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

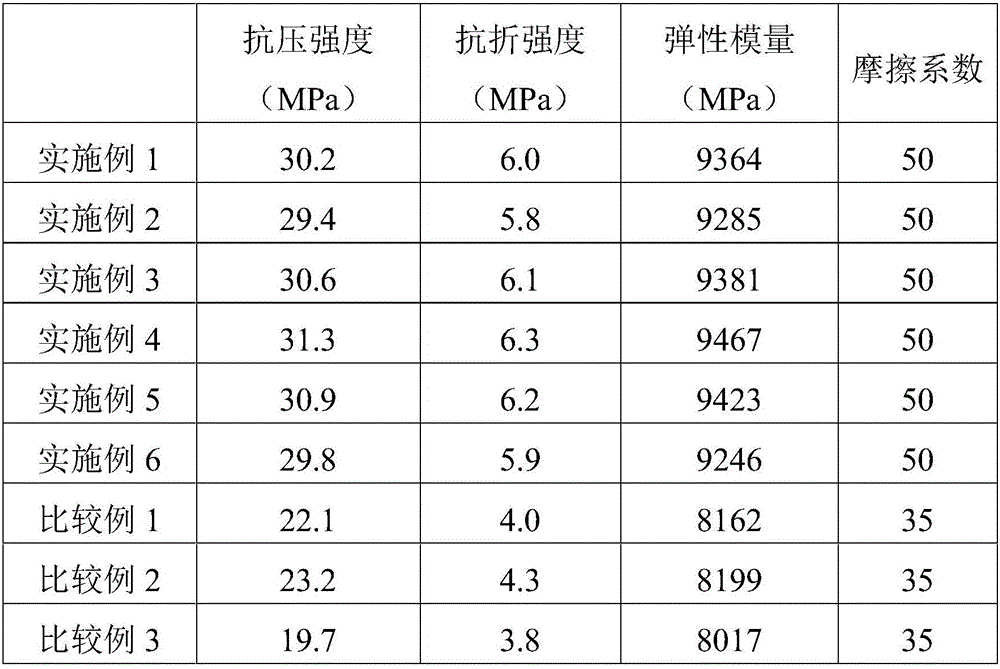

Examples

Embodiment 1

[0025] Embodiment 1: a kind of anti-skidding rain fog asphalt pavement material, the composition of described anti-skid rain fog asphalt pavement material is counted by the following parts by weight: 68 parts of asphalt gravel, 12 parts of cement, 53 parts of mineral powder, 32 parts of limestone, 7 parts of ceramsite, 15 parts of medium sand, 11 parts of emulsifier, 11 parts of smoke suppressant, 6 parts of curing agent, 5 parts of filler and 142 parts of water.

[0026] The smoke suppressant is silica powder, the particle size of the medium sand is 0.28 mm, the asphalt macadam is AM-20 hot-mix asphalt macadam, and the mineral powder is alkaline mineral powder with a fineness of 30 μm , the ceramsite is fly ash ceramsite, the medium sand is quartz sand, the emulsifier is sodium alkylbenzene sulfonate, and the curing agent is aliphatic polyamine curing agent and aromatic ring polyamines A mixture of curing agents, the filler is nano-scale aluminum oxide particles, and the ceme...

Embodiment 2

[0027] Embodiment 2: a kind of anti-skidding rain fog asphalt pavement material, the composition of described anti-skid rain fog asphalt pavement material is counted by the following parts by weight: 73 parts of asphalt gravel, 18 parts of cement, 42 parts of mineral powder, 14 parts of limestone, 1 part of ceramsite, 16 parts of medium sand, 18 parts of emulsifier, 10 parts of smoke suppressant, 7 parts of curing agent, 8 parts of filler and 127 parts of water.

[0028] The smoke suppressant is silica powder, the particle size of the medium sand is 0.34 mm, the asphalt macadam is AM-20 hot-mix asphalt macadam, and the mineral powder is alkaline mineral powder with a fineness of 50 μm , the ceramsite is a mixture of shale ceramsite and fly ash ceramsite, the medium sand is quartz sand, the emulsifier is sodium alkylbenzene sulfonate, and the curing agent is an aliphatic polyamine curing agent , the filler is nano-scale aluminum oxide particles, and the cement is composite ceme...

Embodiment 3

[0029] Embodiment 3: a kind of anti-skidding rain fog asphalt pavement material, the composition of described anti-skid rain fog asphalt pavement material is counted by the following parts by weight: 64 parts of asphalt gravel, 19 parts of cement, 74 parts of mineral powder, 25 parts of limestone, 3 parts of ceramsite, 17 parts of medium sand, 10 parts of emulsifier, 12 parts of smoke suppressant, 9 parts of curing agent, 4 parts of filler and 100 parts of water.

[0030] The smoke suppressant is silica powder, the particle size of the medium sand is 0.37 mm, the asphalt macadam is AM-20 hot-mix asphalt macadam, and the mineral powder is alkaline mineral powder with a fineness of 37 μm , the ceramsite is shale ceramsite, the medium sand is quartz sand, the emulsifier is sodium alkylbenzene sulfonate, the curing agent is an aromatic ring polyamine curing agent, and the filler is nano Class aluminum oxide particles, the cement is fly ash cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com