A kind of safety, environmental protection, anti-fouling and anti-slip agent and preparation method thereof

A safe, environmentally friendly, anti-slip agent technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of matt, high cost, weak penetration, etc., to improve the anti-skid coefficient, lasting effect, and maintain gloss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

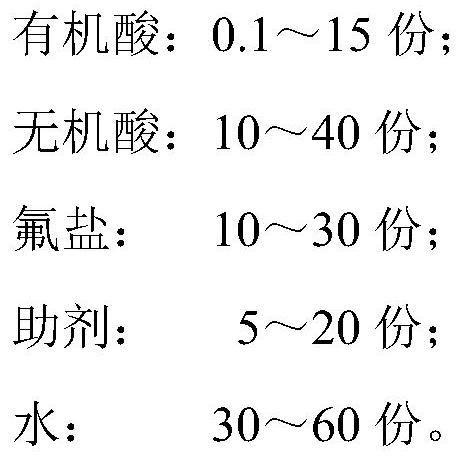

[0026] As a preferred embodiment, the anti-slip agent comprises the following components in parts by weight:

[0027]

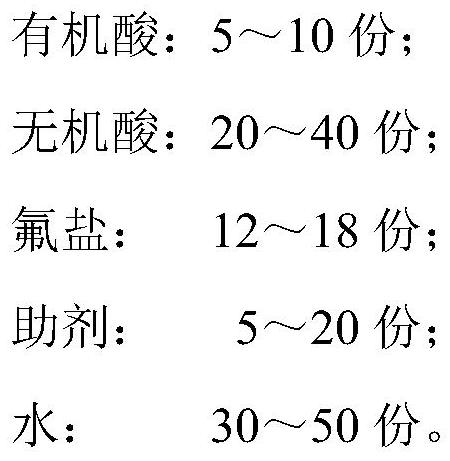

[0028] As a preferred embodiment, the anti-slip agent comprises the following components in parts by weight:

[0029]

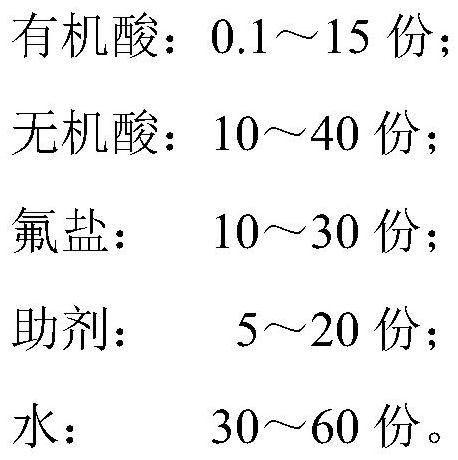

[0030]

[0031] organic acid

[0032] As a preferred embodiment, the organic acid is selected from at least one of citric acid, oxalic acid and tartaric acid.

[0033] The citric acid is a white crystalline powder and is a tricarboxylic acid compound. The ionization constant of citric acid is: pK 1 = 3.13, pK 2 =4.76, pK 3 =6.40.

[0034] Described oxalic acid has another name called oxalic acid, is colorless columnar crystal. An aqueous solution of oxalic acid contains the following ions: C 2 o 4 2- (oxalate ion), H + (hydrogen ion), HC 2 o 4 - (hydrogen oxalate ion). Oxalic acid begins to sublimate at 100°C, rapidly sublimates at 125°C, sublimates in large quantities at 157°C, and begins to decompose.

[0035] Ther...

Embodiment 1

[0097] A safe, environment-friendly, stain-resistant, anti-skid agent, comprising the following components by weight:

[0098]

[0099] Described organic acid is tartaric acid;

[0100] Described mineral acid is made up of 5 parts of nitric acid and 5 parts of hydrofluoric acid;

[0101] The fluoride salt is ammonium fluoride;

[0102] The auxiliary agent is composed of 2.5 parts of triethanolamine and 2.5 parts of silicone oil; the silicone oil is a silane coupling agent modified silicone oil.

[0103] The preparation method of described silane coupling agent modified silicone oil comprises the following steps in parts by weight:

[0104] (l) Pass nitrogen in the three-necked flask for 5 to 10 minutes, remove the original air in the three-necked flask, and then weigh 33.8 parts of methyl hydrogen-containing silicone oil and 33.8 parts of N'-[3-(trimethoxysilyl) propane Base]-N-[(vinylphenyl)methyl]ethylenediamine;

[0105] (2) Dissolve N'-[3-(trimethoxysilyl)propyl]-N-...

Embodiment 2

[0114] A safe, environment-friendly, stain-resistant, anti-skid agent, comprising the following components by weight:

[0115]

[0116] Described organic acid is tartaric acid;

[0117] Described mineral acid is made up of 20 parts of nitric acid and 20 parts of hydrofluoric acid;

[0118] The fluoride salt is ammonium fluoride;

[0119] The auxiliary agent is composed of 10 parts of triethanolamine and 10 parts of silicone oil; the silicone oil is a silane coupling agent modified silicone oil.

[0120] The preparation method of described silane coupling agent modified silicone oil comprises the following steps in parts by weight:

[0121] (l) Pass nitrogen in the three-necked flask for 5 to 10 minutes, remove the original air in the three-necked flask, and then weigh 33.8 parts of methyl hydrogen-containing silicone oil and 33.8 parts of N'-[3-(trimethoxysilyl) propane Base]-N-[(vinylphenyl)methyl]ethylenediamine;

[0122] (2) Dissolve N'-[3-(trimethoxysilyl)propyl]-N-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com