A stabilizer agent for lead-zinc waste rock tailings and its preparation and application

A stabilization and tailings technology, applied in the field of contaminated soil remediation, can solve the problems of complex operability of the treatment process, non-heat resistance of the product, and high product capacity ratio, so as to control the risk of secondary pollution without causing The effect of secondary pollution and reduction of dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The stabilizing agent of the present invention consists of powder and liquid. The powder is composed of the following components: quicklime, sodium bentonite, ammonium phosphate and sodium trithiosulfate. The solution consists of sodium dihydrogen phosphate and water.

[0034] In order to illustrate the practical application effect of the present invention, according to the treatment method and the ratio of the medicaments of the invention, the waste rock tailings in a certain lead-zinc mining area are treated and repaired. According to the detection results of the heavy metal content of waste rock tailings in this mining area, the average content of zinc (Zn) is 24200mg / kg; the average content of lead (Pb) is 22400mg / kg.

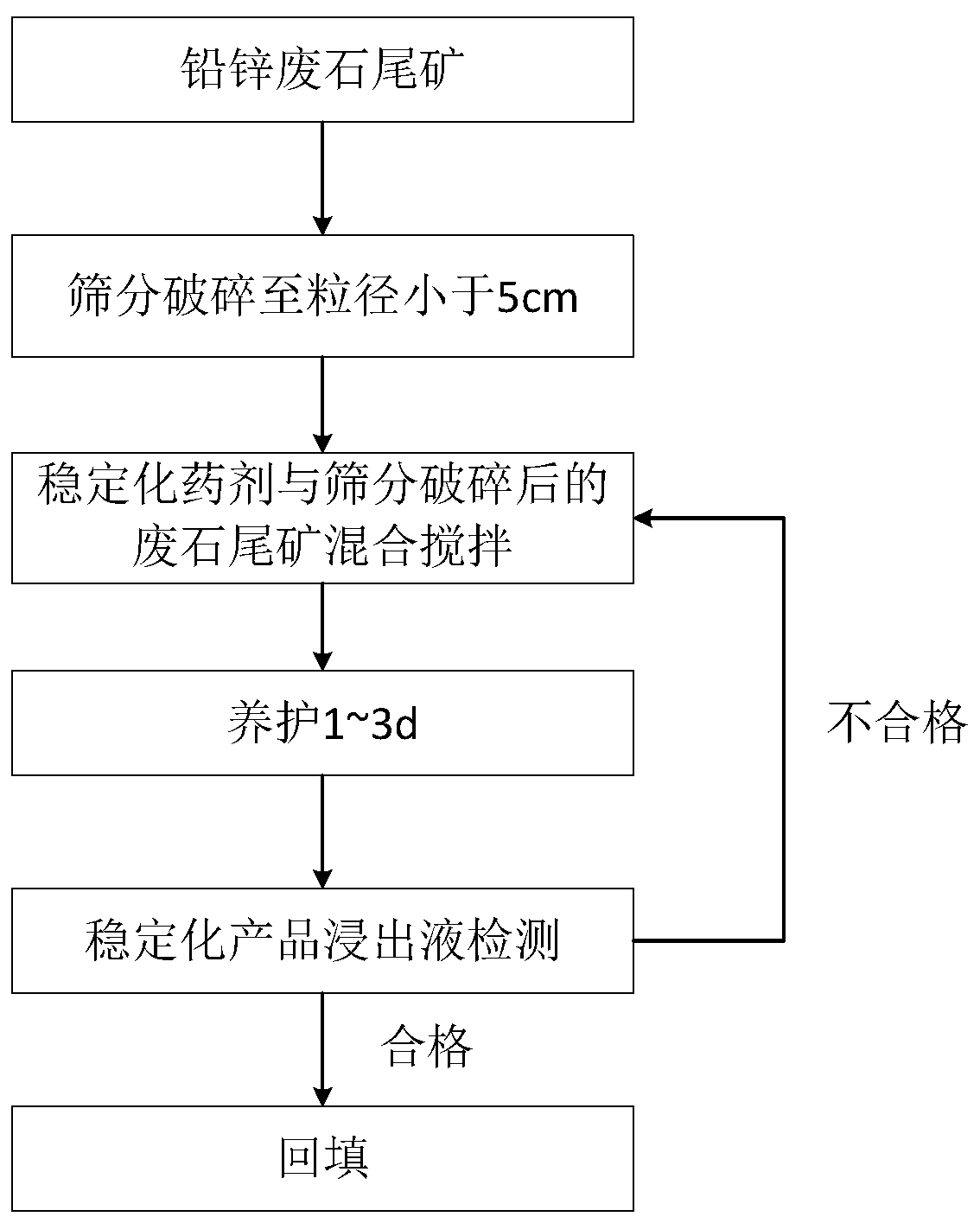

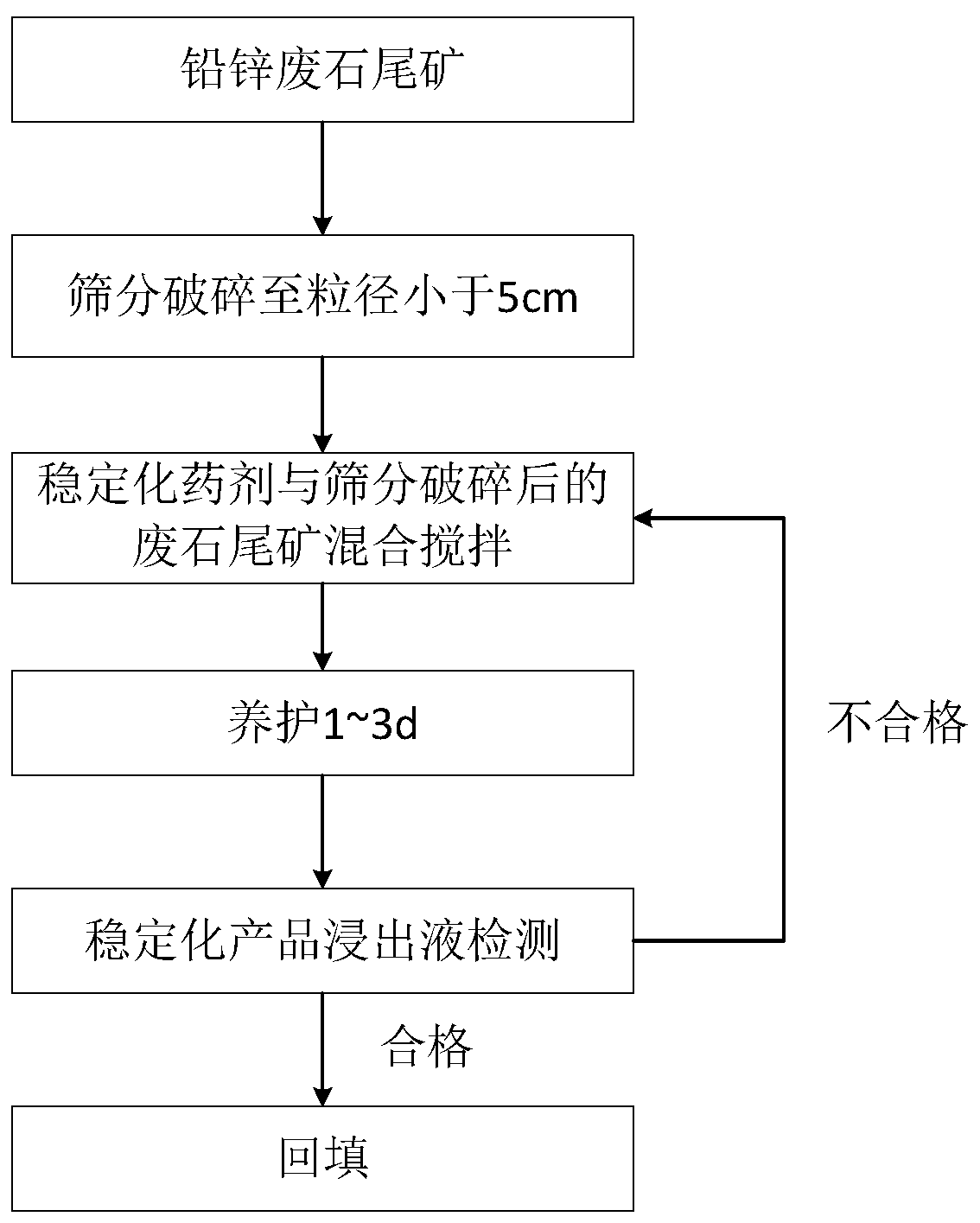

[0035] to combine figure 1 , the method for processing the lead-zinc waste rock tailings by using the stabilizing agent prepared in the present embodiment is as follows:

[0036] (1) Use a vibrating screen to separate the crushed stones with a par...

Embodiment 2

[0048]According to the detection results of the heavy metal content of waste rock tailings in this mining area, the average content of zinc (Zn) is 24200mg / kg; the average content of lead (Pb) is 22400mg / kg. The amount of powder added per 100Kg of waste rock tailings is 4Kg, and the amount of liquid agent added is 1L. The powder composition and its percentage by weight in the powder in the number 1# experimental group are quicklime 54%, kaolinite 18%, ammonium phosphate 20%, sodium trithiosulfate 4%; The percentage by weight in the solution is 4% sodium dihydrogen phosphate and 96% moisture. The powder composition and its percentage by weight in the powder in the number 2# experimental group are quicklime 54%, kaolinite 22%, ammonium phosphate 18%, sodium trithiosulfate 6%; The percentage by weight in the solution is 8% sodium dihydrogen phosphate and 92% moisture. The powder composition and its percentage by weight in the powder in the number 3# experimental group are quick...

Embodiment 3

[0052] According to the detection results of the heavy metal content of waste rock tailings in this mining area, the average content of zinc (Zn) is 24200mg / kg; the average content of lead (Pb) is 22400mg / kg. The amount of powder added per 100Kg of waste rock tailings is 4Kg, and the amount of liquid agent added is 1L. The powder composition and its percentage by weight in the powder in the number 1# experimental group are quicklime 55%, montmorillonite 22%, ammonium phosphate 15%, sodium trithiosulfate 8%, the liquid composition and its The percentage by weight in the solution is 4% sodium dihydrogen phosphate and 96% moisture. The powder composition and its percentage by weight in the powder in the number 2# experimental group are quicklime 54%, montmorillonite 22%, ammonium phosphate 18%, sodium trithiosulfate 6%, the liquid composition and its The percentage by weight in the solution is 8% sodium dihydrogen phosphate and 92% moisture. The powder composition and its perce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com