Sustained-release pesticide fertilizer and preparation method thereof

A medicated fertilizer and slow-release technology, applied in the fields of botanical equipment and methods, pesticides, nitrogen fertilizers, etc., can solve the problems of inability to provide nutrients to crops, no slow-release effect, time-consuming and labor-intensive, etc., saving manpower and improving crop quality. , the effect of improving soil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

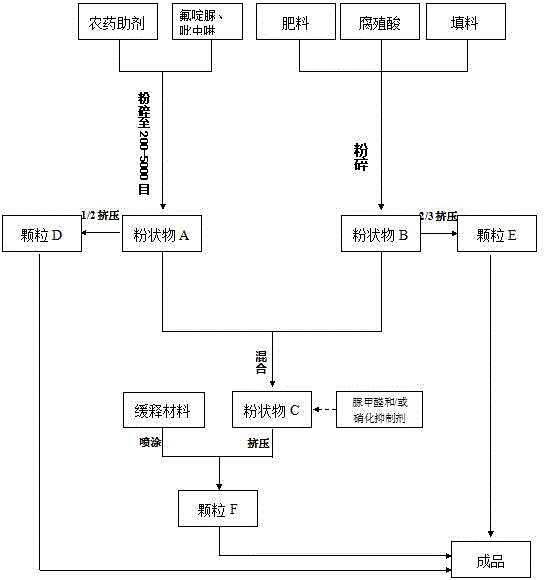

Method used

Image

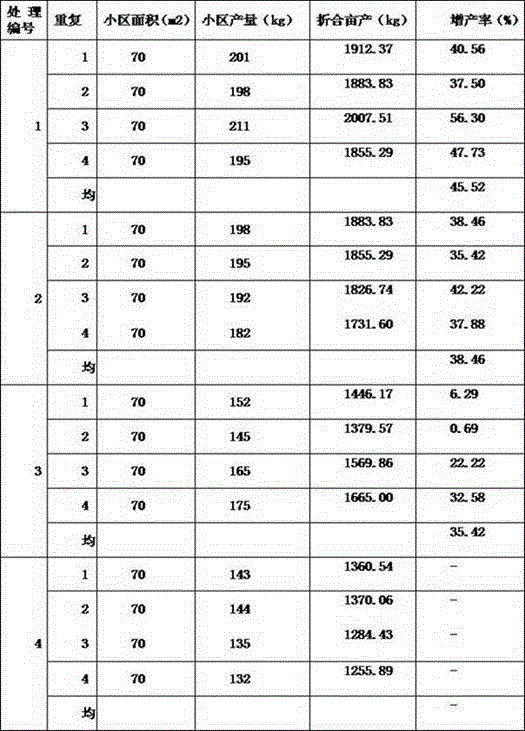

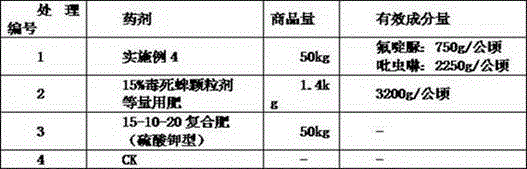

Examples

Embodiment 1

[0023] Chlorfluazuron 0.02kg

[0024] Imidacloprid 0.1kg

[0025] Urea 30kg

[0026] Diammonium phosphate 16kg

[0028] Humic acid 10kg

[0029] Urea formaldehyde 5kg

[0031] Urea-formaldehyde resin 1.88kg

[0032] The preparation method is as follows:

[0033] (1) Accurately weigh the above raw materials for later use;

[0034] (2) Grind 0.02kg of chlorfluazuron, 0.1kg of imidacloprid and 8kg of talc powder with a jet mill to a particle size of 200 mesh to 5000 mesh, then mix evenly to obtain powder A, and 1 / 2 of it is powdered The substance A is extruded and granulated by an extrusion granulator to obtain the medicament granule D;

[0035] (3) Grind 30kg of urea, 16kg of diammonium phosphate, 29kg of potassium sulfate, and 10kg of humic acid and mix them uniformly to obtain powder B. Extrude and granulate 2 / 3 of powder B to obtain fertilizer granules E;

[0036] (4) Mix the remaining 1 / 2 powder A and 1 / 3 pow...

Embodiment 2

[0039] Chlorfluazuron 0.08kg

[0040] Imidacloprid 0.08kg

[0041] Urea 15kg

[0042] Diammonium phosphate 6kg

[0044] Humic acid 40kg

[0045] Urea formaldehyde 10kg

[0046] Talc powder 8kg

[0047] Urea-formaldehyde resin 0.84kg

[0048] The preparation method is as follows:

[0049] (1) Accurately weigh the above raw materials for later use;

[0050] (2) Grind 0.08kg of chlorfluazuron, 0.08kg of imidacloprid and 8kg of talc powder with a jet mill until the particle size is 200 mesh to 5000 mesh, and then mix evenly to obtain powder A, and 1 / 2 of it is powdered The substance A is extruded and granulated by an extrusion granulator to obtain the medicament granule D;

[0051] (3) Grind 15kg of urea, 6kg of diammonium phosphate, 20kg of potassium sulfate, and 40kg of humic acid and mix them uniformly to obtain powder B. Extrude and granulate 2 / 3 of powder B to obtain fertilizer granules E;

[0052] (4) Mix the remaining 1 / 2 powder A i...

Embodiment 3

[0055] Chlorfluazuron 0.2kg

[0056] Imidacloprid 0.2kg

[0057] Urea 30kg

[0058] Diammonium phosphate 16kg

[0059] Potassium sulfate 29kg

[0060] Humic acid 10kg

[0061] Talc powder 8kg

[0062] Nitrification inhibitor 6.6kg

[0063] The preparation method is as follows:

[0064] (1) Accurately weigh the above raw materials for later use;

[0065] (2) Grind 0.2kg of chlorfluazuron, 0.2kg of imidacloprid and 8kg of talc powder with a jet mill until the particle size is 200 mesh to 5000 mesh, and then mix evenly to obtain powder A, and 1 / 2 of it is powdered The substance A is extruded and granulated by an extrusion granulator to obtain the medicament granule D;

[0066] (3) Grind 30kg of urea, 16kg of diammonium phosphate, 29kg of potassium sulfate, and 10kg of humic acid and mix them uniformly to obtain powder B. Extrude and granulate 2 / 3 of powder B to obtain fertilizer granules E;

[0067] (4) Mix the remaining 1 / 2 powder A and 1 / 3 powder B to obtain powder C, ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com